Foundations of Materials Science and Engineering

6th Edition

ISBN: 9781259696558

Author: SMITH

Publisher: MCG

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

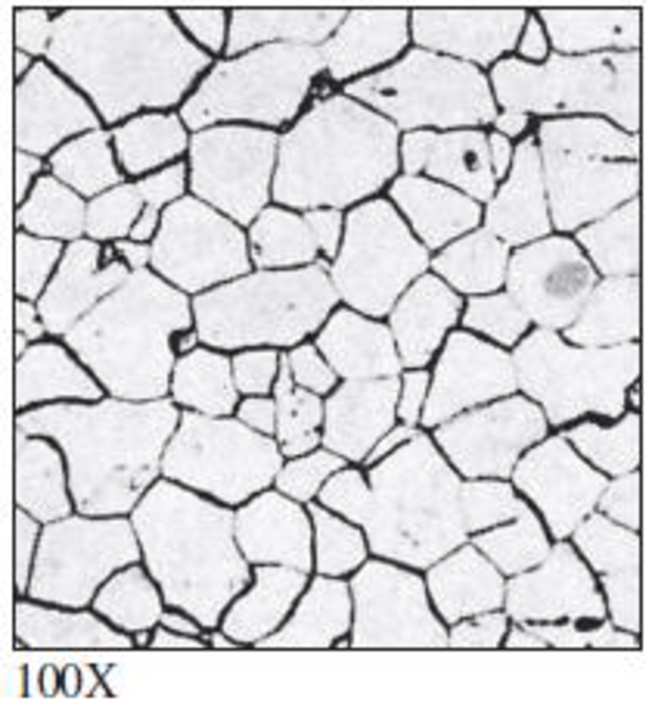

Chapter 4.8, Problem 43AAP

Determine, by counting, the ASTM grain-size number of the low-carbon sheet steel shown in Figure P4.43. This micrograph is at 100×. Classify the grain size according to the value of n, that is, coarse, medium, fine, or ultrafine grain size. Measure the area of the image for your calculations.

Figure P4.43

(©ASM International)

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

In an engineering application, the material is a strip of iron with a fixed crystallographic structure subject

to a tensile load during operation. The part failed (yielded) during operation and needs to be replaced with

a component with better properties. You are told that two other iron strips had failed at yield stresses of

110 and 120 MPa, with grain sizes of 30 microns and 25 microns respectively. The current strip has a grain

size of 20 microns. The diameter of the rod is 1 mm and the load applied is 100 N. What is the yield stress of

the new part C and would you recommend it for operation?

Select one:

a. 140.5, no

Ob. 129.5, yes

OC.

120.5 MPa, no

O d. 133.5 MPa, yes

O e. 123.5 MPa, yes

In an engineering application, the material is a strip of iron with a fixed crystallographic structure subject to a tensile load during operation. The part failed (yielded) during operation and needs to be replaced with a component with better properties. You are told that two other iron strips had failed at yield stresses of 110 and 120 MPa, with grain sizes of 30 microns and 25 microns respectively. The current strip has a grain size of 20 microns. The diameter of the rod is 1 mm and the load applied is 100 N. What is the yield stress of the new part C and would you recommend it for operation?

Select one:

a.120.5 MPa, no

b.140.5, no

c.129.5, yes

d.123.5 MPa, yes

e.133.5 MPa, yes

In an engineering application, the material is a strip of iron with a fixed crystallographic structure subject to a tensile load during operation.

The part failed (yielded) during operation and needs to be replaced with a component with better properties. You are told that two other iron

strips had failed at yield stresses of 110 and 120 MPa, with grain sizes of 30 microns and 25 microns respectively. The current strip has a grain

size of 20 microns. The diameter of the rod is 1 mm and the load applied is 100 N. What is the yield stress of the new part C and would you

recommend it for operation?

Select one:

a.

O b. 129.5, yes

C.

133.5 MPa, yes

e.

120.5 MPa, no

d. 140.5, no

123.5 MPa, yes

Chapter 4 Solutions

Foundations of Materials Science and Engineering

Ch. 4.8 - Prob. 1KCPCh. 4.8 - Define the homogeneous nucleation process for the...Ch. 4.8 - In the solidification of a pure metal, what are...Ch. 4.8 - In the solidification of a metal, what is the...Ch. 4.8 - During solidification, how does the degree of...Ch. 4.8 - Distinguish between homogeneous and heterogeneous...Ch. 4.8 - Describe the grain structure of a metal ingot that...Ch. 4.8 - Distinguish between equiaxed and columnar grains...Ch. 4.8 - How can the grain size of a cast ingot be refined?...Ch. 4.8 - Prob. 10KCP

Ch. 4.8 - Prob. 11KCPCh. 4.8 - Prob. 12KCPCh. 4.8 - Distinguish between a substitutional solid...Ch. 4.8 - What are the conditions that are favorable for...Ch. 4.8 - Prob. 15KCPCh. 4.8 - Prob. 16KCPCh. 4.8 - Prob. 17KCPCh. 4.8 - Prob. 18KCPCh. 4.8 - Describe the structure of a grain boundary. Why...Ch. 4.8 - Describe and illustrate the following planar...Ch. 4.8 - Prob. 21KCPCh. 4.8 - Describe the optical metallography technique. What...Ch. 4.8 - Prob. 23KCPCh. 4.8 - Prob. 24KCPCh. 4.8 - Prob. 25KCPCh. 4.8 - Prob. 26KCPCh. 4.8 - Prob. 27KCPCh. 4.8 - Prob. 28KCPCh. 4.8 - Prob. 29KCPCh. 4.8 - Prob. 30KCPCh. 4.8 - Prob. 31KCPCh. 4.8 - Calculate the size (radius) of the critically...Ch. 4.8 - Prob. 33AAPCh. 4.8 - Prob. 34AAPCh. 4.8 - Calculate the number of atoms in a critically...Ch. 4.8 - Prob. 36AAPCh. 4.8 - Prob. 37AAPCh. 4.8 - Prob. 38AAPCh. 4.8 - Prob. 39AAPCh. 4.8 - Prob. 40AAPCh. 4.8 - Prob. 41AAPCh. 4.8 - Prob. 42AAPCh. 4.8 - Determine, by counting, the ASTM grain-size number...Ch. 4.8 - Prob. 44AAPCh. 4.8 - For the grain structure in Problem 4.43, estimate...Ch. 4.8 - Prob. 46AAPCh. 4.8 - Prob. 47SEPCh. 4.8 - Prob. 48SEPCh. 4.8 - Prob. 49SEPCh. 4.8 - Prob. 50SEPCh. 4.8 - In Chapter 3 (Example Problem 3.11), we calculated...Ch. 4.8 - Prob. 52SEPCh. 4.8 - Prob. 53SEPCh. 4.8 - Prob. 54SEPCh. 4.8 - Prob. 55SEPCh. 4.8 - Prob. 56SEPCh. 4.8 - Prob. 57SEPCh. 4.8 - Prob. 58SEPCh. 4.8 - Prob. 59SEPCh. 4.8 - Prob. 60SEPCh. 4.8 - Prob. 61SEPCh. 4.8 - Prob. 62SEPCh. 4.8 - Prob. 63SEPCh. 4.8 - Prob. 64SEPCh. 4.8 - Prob. 65SEPCh. 4.8 - Prob. 66SEP

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- In an engineering application, the material is a strip of iron with a fixed crystallographic structure subject to a tensile load during operation. The part failed (yielded) during operation and needs to be replaced with a component with better properties. You are told that two other iron strips had failed at yield stresses of 110 and 120 MPa, with grain sizes of 30 microns and 25 microns respectively. The current strip has a grain size of 20 microns. The diameter of the rod is 1 mm and the load applied is 100 N. What is the yield stress of the new part C and would you recommend it for operation?arrow_forwardUsing the values found in the previous two questions, use the Hall-Petch equation and the graph below for a 70 Cu-30 Zn cartridge brass to predict the yield strength (in MPa) of this alloy when the average grain diameter is 1.0 x 10³ mm. Enter only the numerical value, do not include the unit. Grain size, d (mm) 10- 10-2 5 x 103 200 150 100 50 4 8. 12 16 d1/2 (mm-1/2) Yield strength (MPa)arrow_forwardProblem2: Figure 10 is a micrograph of an alloy at a magnification of 200x. Find the ASTM grain size. 8 cmarrow_forward

- 4.48 Determine the ASTM grain-size number if 30 grains per square inch are measured at a mag- nification of 250X.arrow_forwardDetermine the ASTM grain size number of a metal specimen if 25 grains per square inch are measured at a magnification of 100x Solution please. Thankyouarrow_forwardQ2. Using the intercept method, determine the average grain size, in millimeters, of the specimen whose microstructure is shown in Figure c use at least seven straight- line segments. Assume the length of each segment is 80 mm, consider the magnification is 300 X. 6 Q3. Use the ASTM method to find the grain size for figure d, consider the magnification is 200X. darrow_forward

- The following is a schematic micrograph that represents the microstructure of some hypothetical metal. 100 μη Determine the following: (a) Mean intercept length (b) ASTM grain size number, Garrow_forwardIf 32 grains per square inch are measured at a magnification of 800x in a hypothetical metal's micrograph, Determine the ASTM grain size number. Round-off to the nearest whole number. How many grains would there be per square inch if the magnification is 200x? Round-off to the nearest whole number.arrow_forwardChromium (Cr) has the Body-Centered Cubic (BCC) crystal structure. The edge length is a 0.288 nm. What is the linear density in atoms/nm along direction [111P Select one: O a. 7.48 b. 3.18 c. 6.37 d. 4.50 O e. 4.01 Europium has the Body-Centered Cubic (BCC) crystal structure shown in the figure below The radius of the Europium atom is r= 0.204 nm. What is the planar density in atoms/nm im plane (200)2 Plare(200)arrow_forward

- 9. Consider a metal rod, whose grain size can be adjusted by different processing techniques. The graph below shows how the yield stress changes with grain size d; the x-axis is logarithmic. The curve reaches a limiting value of 60 MPa as indicated by the horizontal dashed line on the y-axis, for very large grain sizes. Also, you are given the information that at d = 25 microns (vertical dashed line), the yield stress is 100 MPa. Using this information, what will be the yield stress at d = 5 microns? Select the closest numerical value. Use the Hall-Petch relation in working out your answer. Yield stress (MPa) ● ● 228882S 130 120 110 100 60 10⁰ 10¹ 10² Grain size d (microns) 132.4 MPa 149.4 MPa 165.2 MPa 156.3 MPa 10arrow_forwardBriefly explain the ASTM grain-size standardarrow_forward4. The average grain diameter for a brass material was measured as a function of time at T, which is tabulated below at two different times: Time (min) Grain Diameter (mm) 30 90 3.9 × 10-2 6.6 × 10-2 (a) What was the original grain diameter (using n=2)? (b) What grain diameter would you predict after time, t, at temperature, T? Use T = 650 °C; t = 150 min; n = 2 in the grain size equationarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY

Explanation of Solidification of Metals & Alloys | Manufacturing Processes; Author: Magic Marks;https://www.youtube.com/watch?v=G5z9KknF_s8;License: Standard Youtube License