Laser News Technology, Inc. manufactures computerized laser printing equipment used by newspaper publishers throughout North America. In recent years, the company’s market share has been eroded by stiff competition from Asian and European competitors. Price and product quality are the two key areas in which companies compete in this market.

Ben McDonough, Laser News Technology’s president, decided to devote more resources to the improvement of product quality after learning that his company’s products had been ranked fourth in product quality in a recent survey of newspaper publishers. He believed that the company could no longer afford to ignore the importance of product quality. McDonough set up a task force that he headed to implement a formal quality-improvement program. Included on the task force were representatives from engineering, sales, customer service, production, and accounting, as McDonough believed this was a companywide program and all employees should share the responsibility for its success.

After the first meeting of the task force, Sheila Hayes, manager of sales, asked Tony Reese, the production manager, what he thought of the proposed program. Reese replied, “I have reservations. Quality is too abstract to be attaching costs to it and then to be holding you and me responsible for cost improvements. I like to work with goals that I can see and count! I don’t like my annual income to be based on a decrease in quality costs; there are too many variables that we have no control over!”

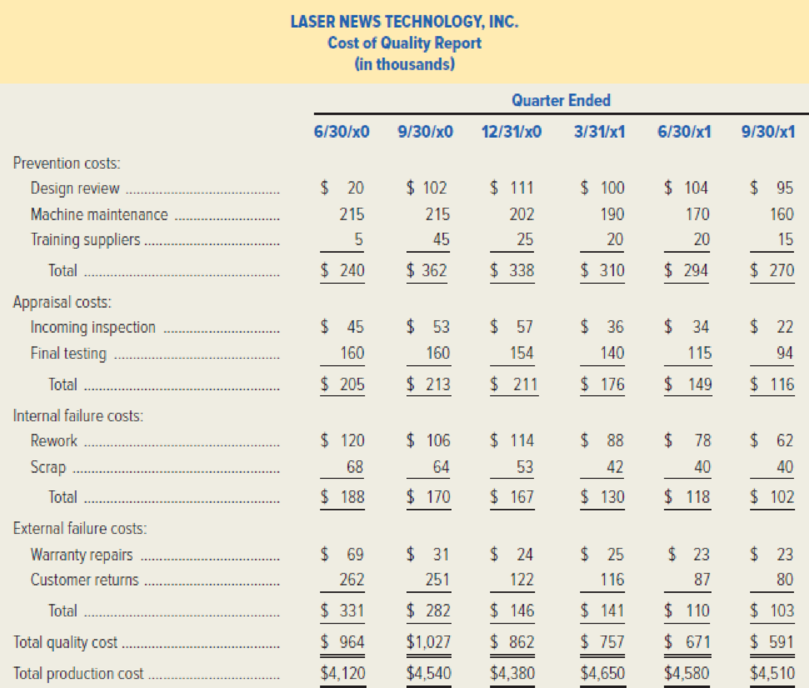

Laser News Technology’s quality-improvement program has now been in operation for 18 months, and the following quality cost report has recently been issued. As they were reviewing the report, Hayes asked Reese what he thought of the quality program now. “The work is really moving through the Production Department,” replied Reese. “We used to spend time helping the Customer Service Department solve their problems, but they are leaving us alone these days. I have no complaints so far. I’ll be anxious to see how much the program increases our bonuses.”

Required:

- 1. Identify at least three factors that should be present for an organization to successfully implement a quality improvement program.

- 2. By analyzing the cost of quality report presented, determine if Laser News Technology’s quality improvement program has been successful. List specific evidence to support your answer.

- 3. Discuss why Tony Reese’s current reaction to the quality improvement program is more favorable than his initial reaction.

- 4. Laser News Technology’s president believed that the quality improvement program was essential and that the firm could no longer afford to ignore the importance of product quality. Discuss how the company could measure the opportunity cost of not implementing the quality-improvement program.

Want to see the full answer?

Check out a sample textbook solution

Chapter 8 Solutions

Managerial Accounting: Creating Value in a Dynamic Business Environment

- Maxwell Company produces a variety of kitchen appliances, including cooking ranges and dishwashers. Over the past several years, competition has intensified. In order to maintainand perhaps increaseits market share, Maxwells management decided that the overall quality of its products had to be increased. Furthermore, costs needed to be reduced so that the selling prices of its products could be reduced. After some investigation, Maxwell concluded that many of its problems could be traced to the unreliability of the parts that were purchased from outside suppliers. Many of these components failed to work as intended, causing performance problems. Over the years, the company had increased its inspection activity of the final products. If a problem could be detected internally, then it was usually possible to rework the appliance so that the desired performance was achieved. Management also had increased its warranty coverage; warranty work had been increasing over the years. David Haight, president of Maxwell Company, called a meeting with his executive committee. Lee Linsenmeyer, chief engineer; Kit Applegate, controller; and Jeannie Mitchell, purchasing manager, were all in attendance. How to improve the companys competitive position was the meetings topic. The conversation of the meeting was recorded as seen on the following page: DAVID: We need to find a way to improve the quality of our products and at the same time reduce costs. Lee, you said that you have done some research in this area. Would you share your findings? LEE: As you know, a major source of our quality problems relates to the poor quality of the parts we acquire from the outside. We have a lot of different parts, and this adds to the complexity of the problem. What I thought would be helpful would be to redesign our products so that they can use as many interchangeable parts as possible. This will cut down the number of different parts, make it easier to inspect, and cheaper to repair when it comes to warranty work. My engineering staff has already come up with some new designs that will do this for us. JEANNIE: I like this idea. It will simplify the purchasing activity significantly. With fewer parts, I can envision some significant savings for my area. Lee has shown me the designs so I know exactly what parts would be needed. I also have a suggestion. We need to embark on a supplier evaluation program. We have too many suppliers. By reducing the number of different parts, we will need fewer suppliers. And we really dont need to use all the suppliers that produce the parts demanded by the new designs. We should pick suppliers that will work with us and provide the quality of parts that we need. I have done some preliminary research and have identified five suppliers that seem willing to work with us and assure us of the quality we need. Lee may need to send some of his engineers into their plants to make sure that they can do what they are claiming. DAVID: This sounds promising. Kit, can you look over the proposals and their estimates and give us some idea if this approach will save us any money? And if so, how much can we expect to save? KIT: Actually, I am ahead of the game here. Lee and Jeannie have both been in contact with me and have provided me with some estimates on how these actions would affect different activities. I have prepared a handout that includes an activity table revealing what I think are the key activities affected. I have also assembled some tentative information about activity costs. The table gives the current demand and the expected demand after the changes are implemented. With this information, we should be able to assess the expected cost savings. Additionally, the following activity cost data are provided: Purchasing parts: Variable activity cost: 30 per part number; 20 salaried clerks, each earning a 45,000 annual salary. Each clerk is capable of processing orders associated with 100 part numbers. Inspecting parts: Twenty-five inspectors, each earning a salary of 40,000 per year. Each inspector is capable of 2,000 hours of inspection. Reworking products: Variable activity cost: 25 per unit reworked (labor and parts). Warranty: Twenty repair agents, each paid a salary of 35,000 per year. Each repair agent is capable of repairing 500 units per year. Variable activity costs: 15 per product repaired. Required: 1. Compute the total savings possible as reflected by Kits handout. Assume that resource spending is reduced where possible. 2. Explain how redesign and supplier evaluation are linked to the savings computed in Requirement 1. Discuss the importance of recognizing and exploiting internal and external linkages. 3. Identify the organizational and operational activities involved in the strategy being considered by Maxwell Company. What is the relationship between organizational and operational activities?arrow_forwardLisa currently manages the polished chrome division of Whispering Broadway, a business that specializes in ceiling light fixtures. Its performance has been stable for the past few years. However, the crystal division has been losing market share, while the rustic iron and chrome divisions have been growing. For the most part, executives feel that these changes are a result of customer preferences and current trends versus the quality or prices of their products. While they expect preferences to return to the crystal product line in the next five years, a short-term decision must be made now. Budgeted financial information for Whispering Broadway's upcoming fiscal year is presented below for each division Sales Variable costs Contribution margin Fixed costs Operating income Chrome $1,230,000 753,000 477,000 236.000 Crystal $424.000 298.000 126.000 236,000 $241.000 $(110,000) Iron $752,000 313,000 All foxed costs are currently assigned evenly to all divisions. 439,000 236,000 $203.000arrow_forwardAt the beginning of the last quarter of 20x1, Youngston, Inc., a consumer products firm, hired Maria Carrillo to take over one of its divisions. The division manufactured small home appliances and was struggling to survive in a very competitive market. Maria immediately requested a projected income statement for 20x1. In response, the controller provided the following statement: After some investigation, Maria soon realized that the products being produced had a serious problem with quality. She once again requested a special study by the controllers office to supply a report on the level of quality costs. By the middle of November, Maria received the following report from the controller: Maria was surprised at the level of quality costs. They represented 30 percent of sales, which was certainly excessive. She knew that the division had to produce high-quality products to survive. The number of defective units produced needed to be reduced dramatically. Thus, Maria decided to pursue a quality-driven turnaround strategy. Revenue growth and cost reduction could both be achieved if quality could be improved. By growing revenues and decreasing costs, profitability could be increased. After meeting with the managers of production, marketing, purchasing, and human resources, Maria made the following decisions, effective immediately (end of November 20x1): a. More will be invested in employee training. Workers will be trained to detect quality problems and empowered to make improvements. Workers will be allowed a bonus of 10 percent of any cost savings produced by their suggested improvements. b. Two design engineers will be hired immediately, with expectations of hiring one or two more within a year. These engineers will be in charge of redesigning processes and products with the objective of improving quality. They will also be given the responsibility of working with selected suppliers to help improve the quality of their products and processes. Design engineers were considered a strategic necessity. c. Implement a new process: evaluation and selection of suppliers. This new process has the objective of selecting a group of suppliers that are willing and capable of providing nondefective components. d. Effective immediately, the division will begin inspecting purchased components. According to production, many of the quality problems are caused by defective components purchased from outside suppliers. Incoming inspection is viewed as a transitional activity. Once the division has developed a group of suppliers capable of delivering nondefective components, this activity will be eliminated. e. Within three years, the goal is to produce products with a defect rate less than 0.10 percent. By reducing the defect rate to this level, marketing is confident that market share will increase by at least 50 percent (as a consequence of increased customer satisfaction). Products with better quality will help establish an improved product image and reputation, allowing the division to capture new customers and increase market share. f. Accounting will be given the charge to install a quality information reporting system. Daily reports on operational quality data (e.g., percentage of defective units), weekly updates of trend graphs (posted throughout the division), and quarterly cost reports are the types of information required. g. To help direct the improvements in quality activities, kaizen costing is to be implemented. For example, for the year 20x1, a kaizen standard of 6 percent of the selling price per unit was set for rework costs, a 25 percent reduction from the current actual cost. To ensure that the quality improvements were directed and translated into concrete financial outcomes, Maria also began to implement a Balanced Scorecard for the division. By the end of 20x2, progress was being made. Sales had increased to 26,000,000, and the kaizen improvements were meeting or beating expectations. For example, rework costs had dropped to 1,500,000. At the end of 20x3, two years after the turnaround quality strategy was implemented, Maria received the following quality cost report: Maria also received an income statement for 20x3: Maria was pleased with the outcomes. Revenues had grown, and costs had been reduced by at least as much as she had projected for the two-year period. Growth next year should be even greater as she was beginning to observe a favorable effect from the higher-quality products. Also, further quality cost reductions should materialize as incoming inspections were showing much higher-quality purchased components. Required: 1. Identify the strategic objectives, classified by the Balanced Scorecard perspective. Next, suggest measures for each objective. 2. Using the results from Requirement 1, describe Marias strategy using a series of if-then statements. Next, prepare a strategy map. 3. Explain how you would evaluate the success of the quality-driven turnaround strategy. What additional information would you like to have for this evaluation? 4. Explain why Maria felt that the Balanced Scorecard would increase the likelihood that the turnaround strategy would actually produce good financial outcomes. 5. Advise Maria on how to encourage her employees to align their actions and behavior with the turnaround strategy.arrow_forward

- Paterson Company, a U.S.-based company, manufactures and sells electronic components worldwide. Virtually all its manufacturing takes place in the United States. The company has marketing divisions throughout Europe, including France. Debbie Kishimoto, manager of this division, was hired from a competitor 3 years ago. Debbie, recently informed of a price increase in one of the major product lines, requested a meeting with Jeff Phillips, marketing vice president. Their conversation follows. Debbie: Jeff, I simply dont understand why the price of our main product has increased from 5.00 to 5.50 per unit. We negotiated an agreement earlier in the year with our manufacturing division in Philadelphia for a price of 5.00 for the entire year. I called the manager of that division. He said that the original price was still acceptablethat the increase was a directive from headquarters. Thats why I wanted to meet with you. I need some explanations. When I was hired, I was told that pricing decisions were made by the divisions. This directive interferes with this decentralized philosophy and will lower my divisions profits. Given current market conditions, there is no way we can pass on the cost increase. Profits for my division will drop at least 600,000 if this price is maintained. I think a midyear increase of this magnitude is unfair to my division. Jeff: Under normal operating conditions, headquarters would not interfere with divisional decisions. But as a company, we are having some problems. What you just told me is exactly why the price of your product has been increased. We want the profits of all our European marketing divisions to drop. Debbie: What do you mean that you want the profits to drop? That doesnt make any sense. Arent we in business to make money? Jeff: Debbie, what you lack is corporate perspective. We are in business to make money, and thats why we want European profits to decrease. Our U.S. divisions are not doing well this year. Projections show significant losses. At the same time, projections for European operations show good profitability. By increasing the cost of key products transferred to Europeto your division, for examplewe increase revenues and profits in the United States. By decreasing your profits, we avoid paying taxes in France. With losses on other U.S. operations to offset the corresponding increase in domestic profits, we avoid paying taxes in the United States as well. The net effect is a much-needed increase in our cash flow. Besides, you know how hard it is in some of these European countries to transfer out capital. This is a clean way of doing it. Debbie: Im not so sure that its clean. I cant imagine the tax laws permitting this type of scheme. There is another problem, too. You know that the companys bonus plans are tied to a divisions profits. This plan could cost all of the European managers a lot of money. Jeff: Debbie, you have no reason to worry about the effect on your bonusor on our evaluation of your performance. Corporate management has already taken steps to ensure no loss of compensation. The plan is to compute what income would have been if the old price had prevailed and base bonuses on that figure. Ill meet with the other divisional managers and explain the situation to them as well. Debbie: The bonus adjustment seems fair, although I wonder if the reasons for the drop in profits will be remembered in a couple of years when Im being considered for promotion. Anyway, I still have some strong ethical concerns about this. How does this scheme relate to the tax laws? Jeff: We will be in technical compliance with the tax laws. In the United States, Section 482 of the Internal Revenue Code governs this type of transaction. The key to this law, as well as most European laws, is evidence of an arms-length price. Since youre a distributor, we can use the resale price method to determine such a price. Essentially, the arms-length price for the transferred good is backed into by starting with the price at which you sell the product and then adjusting that price for the markup and other legitimate differences, such as tariffs and transportation. Debbie: If I were a French tax auditor, I would wonder why the markup dropped from last year to this year. Are we being good citizens and meeting the fiscal responsibilities imposed on us by each country in which we operate? Jeff: Well, a French tax auditor might wonder about the drop in markup. But, the markup is still within reason, and we can make a good argument for increased costs. In fact, weve already instructed the managers of our manufacturing divisions to legitimately reassign as many costs as they can to the European product lines. So far, they have been very successful. I think our records will support the increase that you are receiving. You really do not need to be concerned with the tax authorities. Our tax department assures me that this has been carefully researchedits unlikely that a tax audit will create any difficulties. Itll all be legal and above board. Weve done this several times in the past with total success. Required: 1. Do you think that the tax-minimization scheme described to Debbie Kishimoto is in harmony with the ethical behavior that should be displayed by top corporate executives? Why or why not? What would you do if you were Debbie? 2. Apparently, the tax department of Paterson Company has been strongly involved in developing the tax-minimization scheme. Assume that the accountants responsible for the decision are CMAs and members of the IMA, subject to the IMA standards of ethical conduct. Review the IMA standards for ethical conduct in Chapter 1. Are any of these standards being violated by the accountants in Patersons tax department? If so, identify them. What should these tax accountants do if requested to develop a questionable taxminimization scheme?arrow_forwardZodiac Sound Company manufactures audio systems, both made-to-order and mass-produced systems that are typically sold to large- scale manufacturers of electronics equipment. For competitive reasons, the company is trying to increase its manufacturing cycle efficiency (MCE) measure. As a strategy for improving its MCE performance, the company is considering a switch to JIT manufacturing. While the company managers have a fairly good feel for the costs of implementing JIT, they are unsure about the benefits of such a move, both in financial and nonfinancial terms. To help inform the ultimate decision regarding a move to a JIT system, you've been asked to provide some input. Fortunately, you've recently attended a continuing professional education (CPE) workshop on the costs and benefits of moving to JIT and therefore feel comfortable responding to management's request. Required: 3. Given the estimated data below, calculate the MCE for both the current manufacturing process and the…arrow_forwardZodiac Sound Company manufactures audio systems, both made-to-order and mass-produced systems that are typically sold to large- scale manufacturers of electronics equipment. For competitive reasons, the company is trying to increase its manufacturing cycle efficiency (MCE) measure. As a strategy for improving its MCE performance, the company is considering a switch to JIT manufacturing. While the company managers have a fairly good feel for the costs of implementing JIT, they are unsure about the benefits of such a move, both in financial and nonfinancial terms. To help inform the ultimate decision regarding a move to a JIT system, you've been asked to provide some input. Fortunately, you've recently attended a continuing professional education (CPE) workshop on the costs and benefits of moving to JIT and therefore feel comfortable responding to management's request. Required: 3. Given the estimated data below, calculate the MCE for both the current manufacturing process and the…arrow_forward

- Quality Industries manufactures large workbenches for industrial use. Yewell Hartnet, the Vice President for marketing at Quality Industries, concluded from market analysis that sales were dwindling for Quality's workbenches due to aggressive pricing by competitors. Quality's workbench sells for $1,690 whereas the competition's comparable workbench sells for $1,500. Yewell determined that a price drop to $1,500 would be necessary to protect its market share and maintain an annual sales level of 14,100 workbenches. Cost data based on sales of 14,100 workbenches: Budgeted Quantity Actual Quantity Actual Cost Direct materials (pounds) 180,500 173,500 $ 3,455,500 Direct labor (hours) 75,000 74,250 827,750 Machine setups (no. of setups) 1,450 1,100 255,500 Mechanical assembly (machine hours) 31,150 284,000 3,761,000 If the profit per unit is maintained, the target cost per unit is (rounded to the nearest whole dollar):arrow_forwardABC Corporation has recently completed a project to reduce total production costs by 5%. Net income has risen as a result, but the stock price has suffered from recent public disclosures about faulty products. The vice president for manufacturing and the controller are concerned that their successful cost-cutting efforts have resulted in lower market valuation. They are beginning to understand that product quality has a cost component and they have asked you, a CMA, to explain the concept of “cost of quality'" to them. A. Define, categorize, and give examples of the "cost of quality." B. What is value chain analysis and how could this impact the company's evaluation of costs? C. What other business process improvement tools may benefit the company?arrow_forwardAsbury Coffee Enterprises (ACE) manufactures two models of coffee grinders: Personal and Commercial. The Personal grinders have a smaller capacity and are less durable than the Commercial grinders. ACE only recently began producing the Commercial model. Since the Introduction of the new product, profits have been steadily declining, although sales have been increasing. The management at ACE belleves that the problem might be in how the accounting system allocates costs to products. The current system at ACE allocates manufacturing overhead to products based on direct labor costs. For the most recent year, which Is representative, manufacturing overhead totaled $2,091,000 based on production of 30,000 Personal grinders and 10,000 Commercial grinders. Direct costs were as follows: Direct materials Direct labor Personal $ 1,448,200 1,034,000 Commercial $ 661,000 708,500 Total $ 2,109,200 1,742,500 Management has determined that overhead costs are caused by three cost drivers. These…arrow_forward

- Tool Industries manufactures large workbenches for industrial use. Sam Hartnet, the Vice President for marketing at Tool Industries, concluded from market analysis that sales were dwindling for Tool's workbenches due to aggressive pricing by competitors. Tool's workbench sells for $1,440 whereas the competition's comparable workbench sells for $1,300. Sam determined that a price drop to $1,300 would be necessary to protect its market share and maintain an annual sales level of 13,600 workbenches. Cost data based on sales of 13,600 workbenches: Budgeted Quantity Actual Quantity Actual Cost Direct materials (pounds) 178,000 171,000 $ 3,453,000 Direct labor (hours) 74,000 73,000 826,500 Machine setups (number of setups) 1,200 1,000 253,000 Mechanical assembly (machine hours) 29,400 282,750 3,756,000 The current cost per unit is (rounded to the nearest whole dollar): Multiple Choice $560. $495. $437. $609. $417.arrow_forwardTool Industries manufactures large workbenches for industrial use. Sam Hartnet, the Vice President for marketing at Tool Industries, concluded from market analysis that sales were dwindling for Tool's workbenches due to aggressive pricing by competitors. Tool's workbench sells for $1,140 whereas the competition's comparable workbench sells for $1,060. Sam determined that a price drop to $1,060 would be necessary to protect its market share and maintain an annual sales level of 13,000 workbenches.Cost data based on sales of 13,000 workbenches: Budgeted Quantity Actual Quantity Actual Cost Direct materials (pounds) 175,000 168,000 $ 3,450,000 Direct labor (hours) 72,800 71,500 825,000 Machine setups (number of setups) 900 880 250,000 Mechanical assembly (machine hours) 273,000 281,250 3,750,000 If the profit per unit is maintained, the target cost per unit is (rounded to the nearest whole dollar): Multiple Choice $489. $557. $516. $424.…arrow_forwardWheelco, Inc., manufactures automobile and truck wheels. The company produces four basic, high-volume wheels used by each of the large automobile and pickup truck manufacturers. Wheelco also has two specialty wheel lines. These are fancy, complicated wheels used inexpensive sports cars. Lately, Wheelco's profits have been declining. Foreign competitors have been undercutting Wheelco's prices in three of its bread-and-butter product lines, and Wheelco's sales volume and market share have declined. In contrast, Wheelco's specialty wheels have been selling steadily, although in relatively small numbers, in spite of three recent price increases. At a recent staff meeting, Wheelco's president made the following remarks: "Our profits are going down the tubes, folks. It costs us 29 dollars to manufacture our A22 wheel. That's our best-seller, with a volume last year of 17,000 units. But our chief competitor is selling basically the same wheel for 27 bucks. I don't see how they can…arrow_forward

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning,

Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning, Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning