Concept explainers

Suppose production requirements in Solved Problem 9.2 (see page 383) increase and require a reduction in cycle time from 3 minutes to 7 minutes. Balance the line once again, using the new cycle time. Note that it is not possible to combine task times so as to group tasks into the minimum number of workstations. This condition occurs in actual balancing problems fairly often.

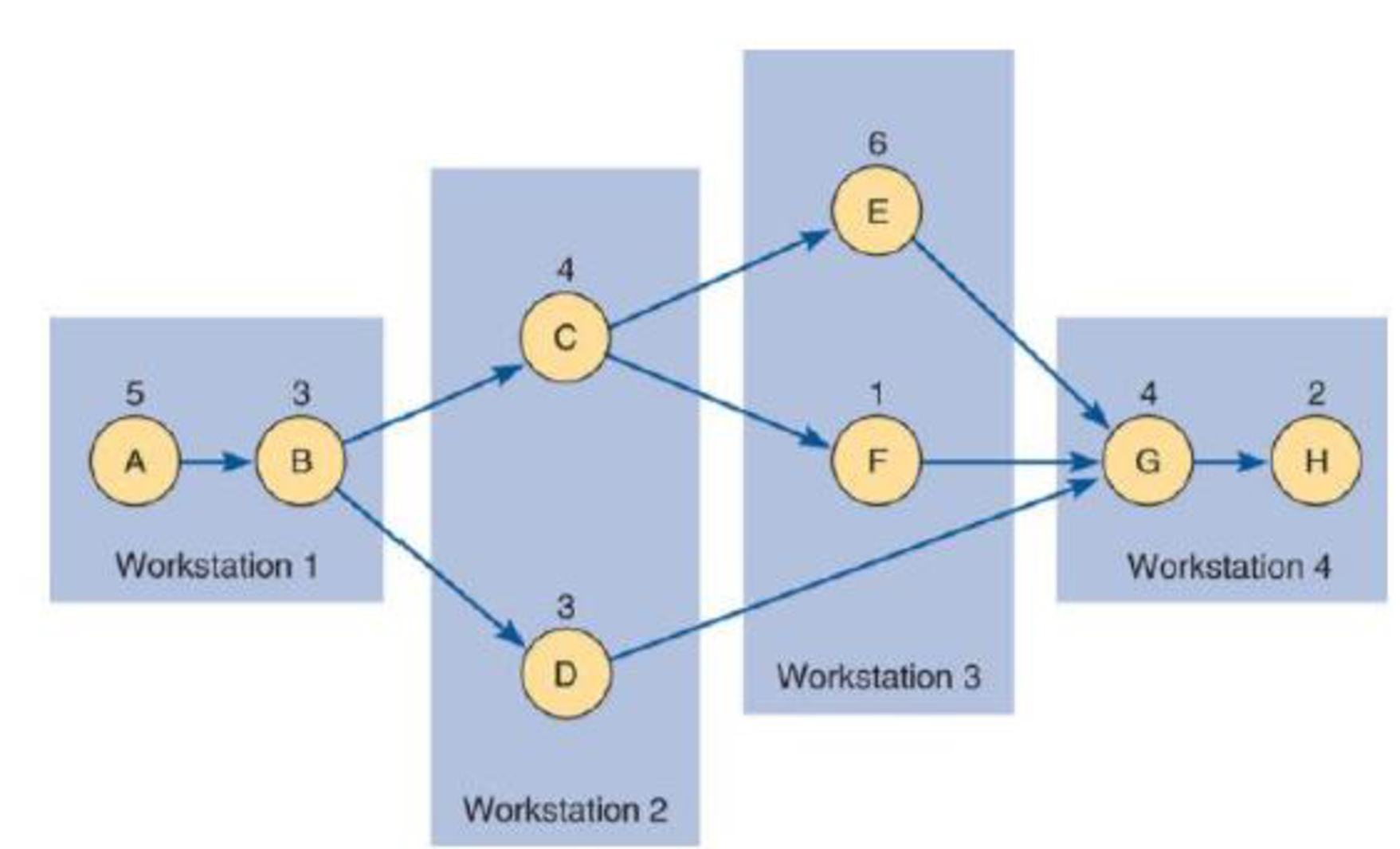

The assembly line whose activities are shown in Figure 9.18 has an 8-minute cycle time. Draw the precedence graph and find the minimum possible number of one-person workstations. Then arrange the work activities into workstations so as to balance the line. What is the efficiency of your line balance?

| TASK | PERFORMANCE TIME (MINUTES) | TASK MUST FOLLOW THIS TASK |

| A | 5 | — |

| B | 3 | A |

| C | 4 | B |

| D | 3 | B |

| E | 6 | C |

| F | 1 | C |

| G | 4 | D,E,F |

| H | 2 | G |

| 28 |

Figure 9.18 Four-Station Solution to the Line-Balancing Problem

Solution

The theoretical minimum number of workstations is:

The precedence graph and one good layout are shown in Figure 9.18:

Want to see the full answer?

Check out a sample textbook solution

Chapter 9 Solutions

Mylab Operations Management With Pearson Etext -- Access Card -- For Operations Management: Sustainability And Supply Chain Management (13th Edition)

- An assembly line for inkjet printers is composed of 8 persons performing different tasks. Compute forthe cycle time if the line has an 8-hour shift and requires 95 units to be finished in one shift.arrow_forwardThe trim line at PW is a small subassembly line that, alongwith other such lines, feeds int1, o the final chassis line.The entire assembly line, which consists of more than 900workstations, is to make PW’s new E cars. The trim line itselfinvolves only 13 work elements and must handle 20 cars perhour. Work-element data are as follows:Work Element Time (Sec) Immediate Predecessor(s)A 2.4 NoneB 0.5 NoneC 2.1 NoneD 1.8 CE 1.1 BF 0.9 A G 2 AH 0.7 FI 0.7 DJ 1.8 H, EK 1.3 JL 1.9 GM 1.1 L, I, Ka. Draw a precedence diagram.b. What cycle time (in minutes) results in the desired outputrate?c. What is the theoretical minimum number of stations?d. Use the longest work element decision rule to balance theline and calculate the efficiency of your solution.e. Use the most followers work element decision rule tobalance the line and calculate the efficiency of yoursolution.arrow_forwardAn assembly plant for the Blood Pressure RX, a portable blood pressure device, has 400 minutes available daily in the plant for the device, and the average demand is 80 units per day. Final assembly requires 6 separate tasks. Information concerning these tasks is given in the following table. Task Performance Time (minutes) Task Must Follow Task Listed Below A 4 - B 1 - C 1 A, B D 3 C E 4 D F 2 E b) Given the demand, what is the cycle time for this operation? The cycle time for this operation is enter your response here minutes/unit (enter your response as a whole number). c) What is the theoretical minimum number of workstations? The theoretical minimum number of workstations is enter your response here stations (enter your response as a whole number and, if your unrounded answer includes decimal values,…arrow_forward

- An assembly line with 17 tasks is to be balanced. The longest task is 2.4 minutes, and the totaltime for all tasks is 18 minutes. The line will operate for 450 minutes per day.a. What are the minimum and maximum cycle times?arrow_forwardThe route shcet for a part is as follows: A - F - E -D - C – B – A - F Two hundred picces will flow through from the first machine A to the final machine F based on the given sequencec of operations. A unit load size of 50 is initially specified at the first machine. However, duc to lot sizing decisions, the unit load size is doubled after processing on machine D. If one vehicle (c.g., lift truck) is used to transport the unit loads from machinc to machine, determine the total number of trips that the vchicle has to make, assuming that the vehicle capacity is one unit load.arrow_forwardDefine process batch and transfer batch and their meaning in each of these applications: MRP, JIT, and bottleneck or constrained resource logic.arrow_forward

- The following table contains order-dependent setup times for four jobs. For safety reasons, jobC cannot follow job A, nor can job A follow job C. Determine the processing sequence that willminimize the total setup time. (Hint: There are 12 alternatives.)Following Job’sSetup Time (hrs.)SetupTime (hrs.) A B C DPrecedingjobA 2 — 5 × 4B 1 7 — 3 2C 3 x 2 — 2D 2 4 3 6 —arrow_forwardA production process at Kenneth Day Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). Q 2.1 units/hr Sawing 5 units/hr Sanding Drilling 5 units/hr Welding 2.5 units/hr a) Sawing is the bottleneck. b) The bottleneck time is 28.57 minutes per unit (round your response to two decimal places). c) The throughput time of the overall system is minutes (round your response to two decimal places). Assembly 0.8 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hrarrow_forwardFrancis Johnson's plant needs to design an efficient assembly line to make a new product. The assembly line needs to produce 15 units per hour, and there is room for only five workstations. The tasks and the order in which they must be performed are shown in th following table. Tasks cannot be split, and it would be too expensive to duplicate any task. TASK TIME (MINUTES) IMMEDIATE PREDECESSOR rint TASK A 2.0 B 2.0 3.0 1.0 А, В, с 3.0 2.0 G 3.0 b. What is the workstation cycle time required to produce 15 units per hour? (Round your answer to 1 decimal place.) Workstation cycle time minutes d. Balance the line to use the fewest possible workstations to meet the cycle time found in part b. Use whatever method you feel is appropriate. What is the efficiency of your line balance, assuming the line operates at the cycle time from part b? (Round your answer to 1 decimal place.)arrow_forward

- A manager wants to assign tasks to workstations as efficiently as possible, and achieve an hourly output of 4 units. The department uses a working time of 56 minutes per hour. Assign the tasks shown in the accompanying precedence diagram (times are in minutes) to workstations using the following rules:arrow_forwardA production process at Kenneth Day Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). 2.1 units/hr Sawing 5 units/hr Sanding Drilling 5 units/hr Welding 2.5 units/hr a) Sawing is the bottleneck. b) The bottleneck time is 28.57 minutes per unit (round your response to two decimal places). c) The throughput time of the overall system is 89.58 minutes (round your response to two decimal places). Assembly Q 0.8 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hrarrow_forwardA firm uses a serial assembly system and needs answers to the following: An output of 900 units per shift (7.5 hours) is desired for a new processing system. The system requires product to pass through four stations where the work content at each station is 30 seconds. What is the required cycle time for such a system?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,