Concept explainers

Yost-Perry Industries (YPI) manufactures a mix of afford able guitars

Want to see the full answer?

Check out a sample textbook solution

Chapter 5 Solutions

Operations Management: Processes and Supply Chains (12th Edition) (What's New in Operations Management)

- The Goodparts Company produces a component that is subsequently used in the aerospace industry. The component consists of three parts (A, B, and C) that are purchased from outside and cost 35, 30, and 10 cents per piece, respectively. Parts A and B are assembled first on assembly line 1, which produces 185 components per hour. Part C undergoes a drilling operation before being finally assembled with the output from assembly line 1. There are, in total, six drilling machines, but at present only three of them are operational. Each drilling machine drills part C at a rate of 80 parts per hour. In the final assembly, the output from assembly line 1 is assembled with the drilled part C. The final assembly line produces at a rate of 205 components per hour. At present, components are produced eight hours a day and five days a week. Management believes that if the need arises, it can add a second shift of eight hours for the assembly lines. The cost of assembly labor is 30 cents per part for…arrow_forwardMotorking Corporation, a market leader in the production of specialized engine additives, is considering introducing a new "gas extender" product. This product is added to an automobile’s gasoline to extend mileage and reduce exhasut emissions. Motorking's manufacturing facility can produce 50,000 cases of the new product per year with a set-up cost of $100,000. The average variable cost per case would be $5. Large orders, (i.e., above 50,000 cases) will be subcontracted to a local refining company. Motorking has signed a secrecy agreement with the vendor that guards the basic process. The variable cost per case, if the new product is produced outside, is $9. Whether the product is manufactured by Motorking or by the vendor, there is a $12 per case cost for marketing and overhead. Motorking's production manager is considering three production levels for the new product: 50,000 cases, 75,000 cases, and 100,000 cases. The level of sales will depend on the state of the economy. Sales…arrow_forwardXYZ Leather Company manufactures and sells two products, wallets and belts, in its two-department plant. Operating data pertaining to the two products are as follows: Wallets Belts Selling price per unit P30 P50 Cost per unit: Variable manufacturing costs P8 P15 Variable marketing costs P2 P3 Fixed manufacturing costs P5 P5 Fixed marketing costs P6 P1 Cutting Finishing…arrow_forward

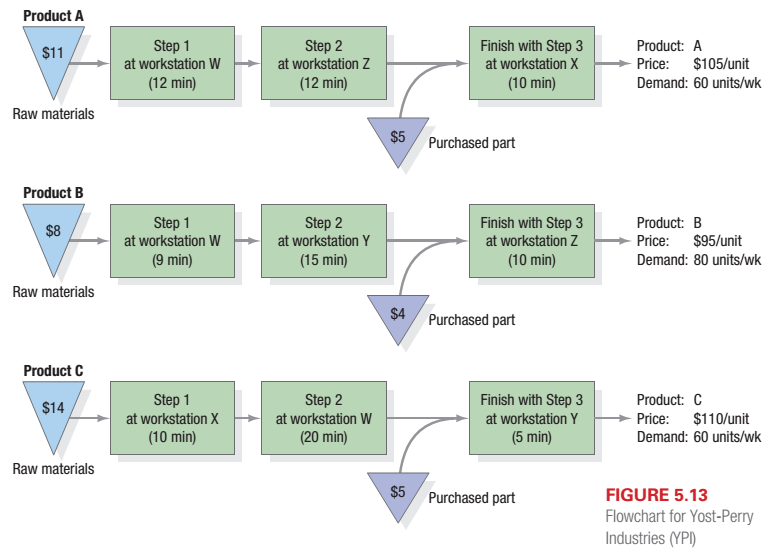

- York-Perry Industries (YPI) manufactures a mix of affordable guitars (A, B, C) that are fabricated and assembled at four different processing stations (W, X, Y, Z). The operation is a batch process with small setup times that can be considered negligible. The product information (price, weekly demand, and processing times) and process sequences are shown below. Purchased parts and raw materials (shown as a per-unit consumption rate) are represented by inverted triangles. YPI is able to make and sell up to the limit of its demand per week with no penalties incurred for not meeting the full demand. Each workstation is staffed by one highly skilled worker who is dedicated to work on that workstation alone and is paid $17 per hour. The plant operates one 8-hour shift per day and operates on a 5-day work week (i.e., 40 hours of production per person per week). Overhead costs are $9,000/week. Product A $11 Step 1 Station W (14 min) Step 2 Station Z (10 min) Raw materials $5 Purchased part…arrow_forwardWhich among the following is a basic information required for Manufacturing Planning and Control O a. Time study data O b. Routing data O c. All the Options O d. Work measurement dataarrow_forward(a) T. Smunt Manufacturing Corp. has the process displayed below. The drilling operation occurs separately from and simultaneously with the sawing and sanding operations. The product only needs to go through one of the three assembly operations (the assembly operations are "parallel"). ASSEMBLY SAWING SANDING 78 min/unit 15 min/unit 15 min/unit WELDING ASSEMBLY DRILLING 25 min/unit 78 min/unit 27 min/unit ASSEMBLY 78 min/unit 1. Which operation is the bottleneck? 2. What is the throughput time for the overall system? 3. If the firm operates 8 hours per day, 22 days per month, what is the monthly capacity of the manufacturing process? 4. Suppose that a second drilling machine is added, and it takes the same time as the original frilling machine. What is the new bottleneck time of the system? 5. Suppose that a second drilling machine is added, and it takes the same time as the original drilling machine. What is the new throughput time?arrow_forward

- Tuff-Rider, Inc., manufactures touring bikes and mountainbikes in a variety of frame sizes, colors, and component com-binations. Identical bicycles are produced in lots of 100. Theprojected demand, lot size, and time standards are shown inthe following table: Item Touring MountainDemand forecast 5,000 units/year 10,000 units/yearLot size 100 units 100 unitsStandard processing time .25 hour/unit .50 hour/unitStandard setup time 2 hours/lot 3 hours/lot The shop currently works 8 hours a day, 5 days a week,50 weeks a year. It operates five workstations, each producingone bicycle in the time shown in the table. The shop main-tains a 15 percent capacity cushion. How many workstationswill be required next year to meet expected demand withoutusing overtime and without decreasing the firm’s currentcapacity cushion?arrow_forwardTRX company involved with purely manual assembly process is planning to produce 820 units of output per month. The standard time for the product is 115 min per unit. The company is currently employing 6 workers and having a working period of 8 hours per day with 24 days per month.Average salary for each worker is RM1850 per month. Evaluate the available data and propose the number of operators that must be arranged to perform the overtime work daily in order to meet the production output. The overtime is executed 3 hours every day over the 24 days periodarrow_forwardCarCity is a big retailer for car parts and accessories. The store stocks different types and sizes of car tire. One of the best selling tires is the Tiger Model R125, which is currently purchased from a factory in Indonesia. An analysis of the purchasing operation shows that approximately 3 labor hours are required to process a purchase order, regardless of the quantity purchased. Salaries in the purchasing Department average OMR 12 per hour, including employee benefits. In addition, a detailed analysis of 15 previous purchase orders showed that OMR 132 was spent on telephone, paper, and other consumables directly related to the ordering process . Shipping cost from Indonesia is OMR 230 for a container. A container has a capacity of 800 tires. The lead time for shipments from Indonesia is 15 days. Finally, CarCity’s financial analysts established a holding cost of 20% for this type of tire. The annual demand for the R125 tire is constant at a rate of 8400 units. The store purchases…arrow_forward

- A process loop or machine cycle has these four elements. What parts of machine cycles are valued? Does replacing machine cycle components matter? Do more modules assist with switching?arrow_forwardThe process train functions as a visual instrument that allows stakeholders to get a thorough comprehension of the production system and its dynamics. A process train has numerous advantages and may be applied in various ways. What are the important advantages and applications of employing a process trainarrow_forwardJudy’s Cake Shop makes fresh cakes to customer orders. After receiving the order by Judy’s assistant, which takes 2 minutes, Judy then takes 8 minutes tomix the ingredients for the cake and loads a cake pan for baking. Then the cake is put into the oven for 30 minutes. The oven can hold three cakes at one time. When the cake is taken out of the oven, it is cooled for 1 hour. The assistant then takes 2 minutes to pack the cake for pickup and bills the customer, which takes 3 minutes.a. What is the capacity of the process, and what is the bottleneck?b. What is the throughput time for a typical cake?c. If on average five orders are taken per hour, how many cakes are there in the process (on average)?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,