Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

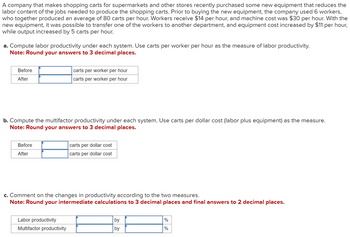

A company that makes shopping carts for supermarkets and other stores recently purchased some new equipment that reduces the labor content of the jobs needed to produce the shopping carts. Prior to buying the new equipment, the company used 6 workers, who together produced an average of 80 carts per hour. Workers receive $14 per hour, and machine cost was $30 per hour. With the new equipment, it was possible to transfer one of the workers to another department, and equipment cost increased by $11 per hour, while output increased by 5 carts per hour.

Transcribed Image Text:A company that makes shopping carts for supermarkets and other stores recently purchased some new equipment that reduces the

labor content of the jobs needed to produce the shopping carts. Prior to buying the new equipment, the company used 6 workers,

who together produced an average of 80 carts per hour. Workers receive $14 per hour, and machine cost was $30 per hour. With the

new equipment, it was possible to transfer one of the workers to another department, and equipment cost increased by $11 per hour,

while output increased by 5 carts per hour.

a. Compute labor productivity under each system. Use carts per worker per hour as the measure of labor productivity.

Note: Round your answers to 3 decimal places.

Before

After

carts per worker per hour

carts per worker per hour

b. Compute the multifactor productivity under each system. Use carts per dollar cost (labor plus equipment) as the measure.

Note: Round your answers to 3 decimal places.

Before

After

carts per dollar cost

carts per dollar cost

c. Comment on the changes in productivity according to the two measures.

Note: Round your intermediate calculations to 3 decimal places and final answers to 2 decimal places.

Labor productivity

Multifactor productivity

by

%

by

%

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Chairs are made in a process with a single resource. There are two types of chairs. The resource's processing time for the first type is 30 minutes and demand for this type is 2.3 chairs per hour. The resource's processing time for the second type is 23 minutes and demand for this type is 2.8 chairs per hour. There is 1 worker at this resource. Instruction: Round your answer to one decimal place. What is the implied utilization (%) of this resource?arrow_forwardConsider the following data: observed time/unit = 6 minutes Performed Rating = 110% Allowance = 25% of normal time shift duration = 6hours Calculate the standard outputs/shift 2) An employee processes 6 insurance policies/day. The company employs 4 employees,each working 8 hours/day.Employee wage/day=620 dollar and daily overhead expanse = 480 dollar.The company is now considering a purchase of new technology which will enable each employee to process 9 insurance policies/day with an increase of 65 dollars in the daily overhead expanse.The company is aiming for at least 30 percent increase in both labor and multifactor productivity after this purchase.Should the company go for this purchase?arrow_forwardA recurring maintenance job in a factory is being done by a three-man crew. Due to the nature of the job and space limitations, it was observed that two of the men were idle 37% of the time; one of the men was also idle an additional of the time, and at any given time only one man was required. The men were each paid P24.00 per hour. Each time the job was performed a set of tools and equipment with a value equivalent to P36.00 per hour was used. If the three-men crew could complete the work in 5 hours, which crew size would be the most economicalarrow_forward

- Four employees at a fast-food restaurant each perform one of the four activities in serving a customer: greet customer, take order, process order, and deliver order. The processing time for each activity is given as follows: Greet customer Take order Process order Deliver order A) 50% Assume demand is unlimited. What is the average labor utilization? B) 68% C) 40% Activity D) 162% Processing time per customer 2 seconds 30 seconds 60 seconds 5 secondsarrow_forward. In the welding operations of a bicycle manufacturer, a bike frame has a flow time of about 11.5 hours. The time in the welding operation is spent as follows: 2 hours waiting in front of the cutting machine for the batch to start, 2 hours waiting for the setupof the machine, 1 hour waiting for the other pieces of the batch to go through cutting, 1 minute at the cutting machine, and 3 hours waiting for the transfer to the welding machine. Then, at the welding machine, the unit spends 1 hour waiting in front of the welding machine for the batch to start, 1 hour waiting for the setup of the welding machine, 0.5 hour waiting for the other pieces of the batch to go through welding, 0.5 minute at the welding machine, and 1 hour waiting for the transfer to the next department. Determine the exact flow time. What is the value-added percentage of the flow time?arrow_forwardPrevost Chemicals manufactures an industrial solvent at its only processing plant. A liquid chemical and labor are the two primary inputs. All other resources are included in manufacturing overhead. The plant never has any work-in-process or finished goods inventories. Information from the previous four periods of production follows: Chemical input (gallons) Labor input (hours) Solvent sales (gallons) Average price of chemical per gallon Average wage rate per hour Average sales price per gallon Manufacturing overhead (total) Required A Required B Required C Required: a. Compute the partial productivity measures for chemical for the four periods. b. Compute the partial productivity measures for labor for the four periods. c. Compute the total factor productivity for the four periods. Complete this question by entering your answers in the tabs below. Period Period 1 125,000 12,500 110,000 Period 1 $ 2.00 28.00 10.26 236,000 Compute the partial productivity measures for chemical for the…arrow_forward

- Navern Corporation manufactures and sells custom home elevators. From the time an order is placed until the time the elevator is installed in the customer's home averages 141 days. The 141 days are spent as follows: Wait time Inspection time Process time Move time Queue time What is Navern's manufacturing cycle efficiency (MCE) for its elevators? Multiple Choice O O 41.1% 30.4% 58.9% 29 days 24 days 34 days 31 days 23 days 57.4%arrow_forwardThe cost of computer equipment does not include the consultant's fee to supervise installation of the equipment. True or Falsearrow_forward.A team of 10 unloaders is employed in good reception bay of a large warehouse. During an 8 hour day 40 lorries arrive and it takes the team 10 minutes to unload each lorry. Each team member is paid RM3 per hour and it costs RM10 per hour to keep lorries waiting. Studies show that increasing the team to 14 men would reduce the unloading time to 7 minutes. Would it be worthwhile increasing the team to 14?arrow_forward

- Benny the Barber owns a one-chair shop. At barber college, they told Benny that his customers would exhibit a Poisson arrival distribution and that he would provide an exponential service distribution. His market survey data indicate that customers arrive at a rate of 4.0 per hour. It will take Benny an average of 8 minutes to give a haircut. Based on these figures, find the following: a. The average number of customers waiting. Note: Round your intermediate calculations to 3 decimal places and final answer to 2 decimal places. Average number of customers waiting b. The average time a customer waits. Note: Round your answer to 2 decimal places. Average waiting time minutesarrow_forwardIn a job shop, effective capacity is only 79 percent of design capacity, and actual output is 53 percent of effective output. What design capacity would be needed to achieve an actual output of 11 jobs per week? What is its effective capacity? a. The Design Capacity needed to achieve the required actual job outputs Blank 1 (round to whole number) b. The Effective Capacity needed to achieve the required actual job outputs = Blank 2 (round to whole number) Blank 1 Add your answerarrow_forwardThe consumer loan division of a major bank wants to determine the size of the staff it would need to process up to 200 loan applications per day. It estimated that each loan officer can process a loan application in approximately 15 minutes. If the utilization of a loan officer is 0.70 (70 percent) and each loan officer works seven hours each day, how many loan officers would be needed to handle that volume of business? Round your answer up to the nearest whole number. loan officersarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.