Consolidated Electric: Inventory Control

Joe Henry, the sole owner and president of the Consolidated Electric Company, reflected on his inventory management problems. He was a major wholesale supplier of equipment and supplies to electrical contractors, and his business hinged on the efficient management of inventories to meet his customers' needs. While Henry had built a very successful business, he was nearing retirement age and wanted to pass along a good inventory management system.

Henry's two sons-in-law were employed in the company. Carl Byerly, the older of the two, had a college degree in mathematics and was very interested in Inventory formulas and computers. The other son-in-law, Edward Wright, had a degree in biology and was manager of one of the company’s wholesale warehouses.

Joe Henry started the Consolidated Electric Company in the 1940s and built it Into a highly profitable business. In 2016 the company had achieved S10 million in sales and earned SI million in pretax profits. Consolidated Electric was currently the twelfth largest electrical wholesaler in the country.

Consolidated Electric operates through four warehouses in Iowa (Des Moines, Cedar Rapids, Sioux City, and Davenport). From these sites, contractors in Iowa, Minnesota, Nebraska, Wisconsin, Illinois, and Missouri are supplied with a wide range of electrical equipment, including wire, electrical boxes, connectors, lighting fixtures, and electrical controllers. The company stocks 20,000 separate line items In Its Inventory purchased from 200 different manufacturers. (A line Item is defined as a particular item carried at a particular location.) These items range from less than 1 cent each to several hundred dollars for the largest electrical controllers.

Of the 20,000 line items, a great many are carried to provide a full line of service. For example, the top 2,000 items account for 50 percent of the sales and the bottom 10,000 items for only 20 percent. The remaining 8,000 items account for 30 percent of the sales.

The company has continually purged its 20,000 inventory items to carry only those that are demanded at least once a year. As Henry says, “We live and die by good customer service at a reasonable selling price. If we do not meet this objective, the customer will go to another wholesaler or buy directly from the manufacturer.”

Henry explained that he currently managed inventory by using an "earn and turn" concept. According to this concept, the earnings margin multiplied by the inventory turn ratio must equal a constant value of 2.0. For example, if a particular electrical item costs $6 to purchase wholesale and is sold for $10, then the earnings margin is $4 and the earn ratio for this item is $4/$10 = .40. If this item has a turn ratio of 5 times a year (sales are 5 times the average inventory carried), then the product of earn and turn is .4(5) = 2.0. If another item earns more, it can turn slower; if it earns less, it must turn faster.

Each year, Henry sets a target earn-tum ratio for the entire business and a value for each product line. These targets are based on the estimated costs of operations and the return-on-investment goal for the company. As stated above, the current target ratio for the business is 2.0. The purchasing agents and inventory managers at each location are measured by their ability to meet the target earn-turn ratios on their product lines. The actual ratios are reported monthly.

Although earn-turn ratios work quite well in controlling profitability of the business and entire product lines, they do not work very well for individual inventory items. Some line items tend to be in excess supply, while others are often out of stock.

The inventory is currently managed by use of a small computer system. A record for each item is kept and a clerk posts transactions on the record as units are received or issued, thus keeping a running on-hand inventory balance. Periodically, a purchasing agent reviews the records for a particular supplier. Then, using the order point and quantity stored on the record, the purchasing agent places an order for all items that are below their reorder point.

If the total quantities of all items required from a supplier do not meet the purchase discount minimums or a truckload lot, additional items near their reorder points are added to the order. This is not done when the total order size is too far from the minimums, since excessive Inventories would build up.

The order quantity and reorder point on each record are based on judgment and past experience. Generally speaking, a three-month supply is ordered for low-cost items and as little as a one-month supply for expensive items. Most lines are reviewed on a weekly basis.

Consolidated Electric had been converting its inventory records to a new software system. At the present time, an on-hand balance is maintained on the computer, and an accurate history of all orders placed, receipts, and issues is kept.

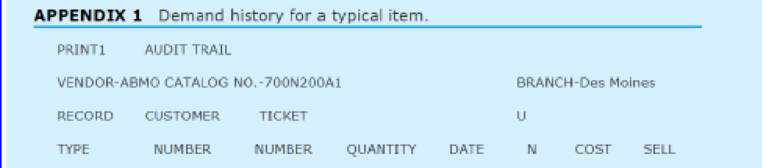

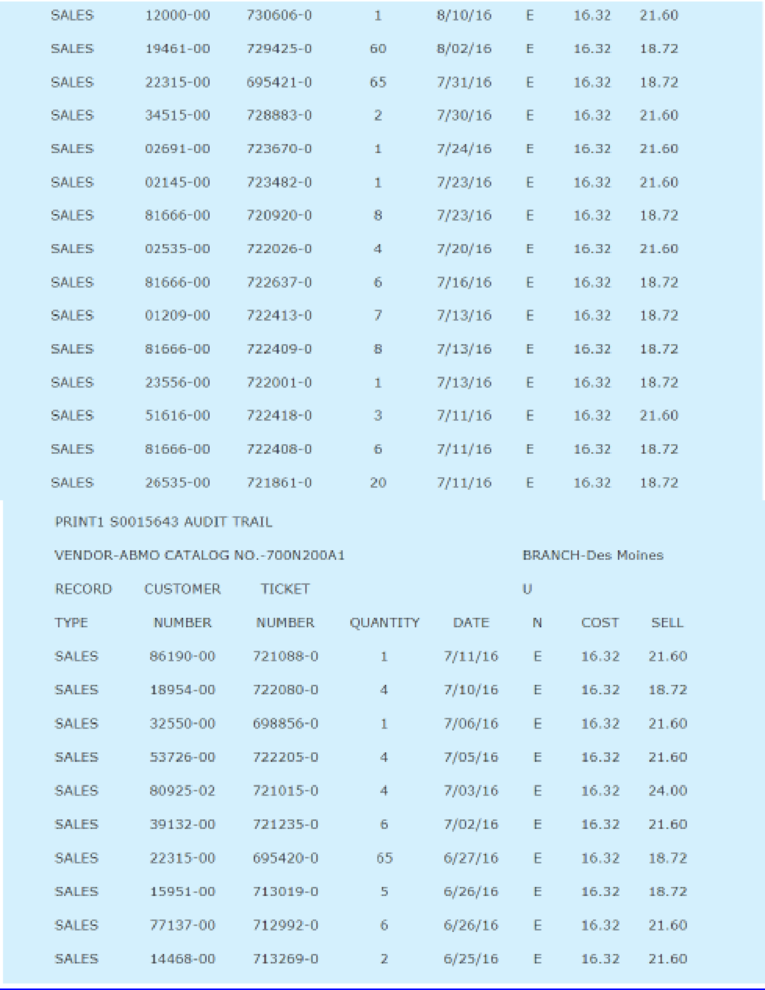

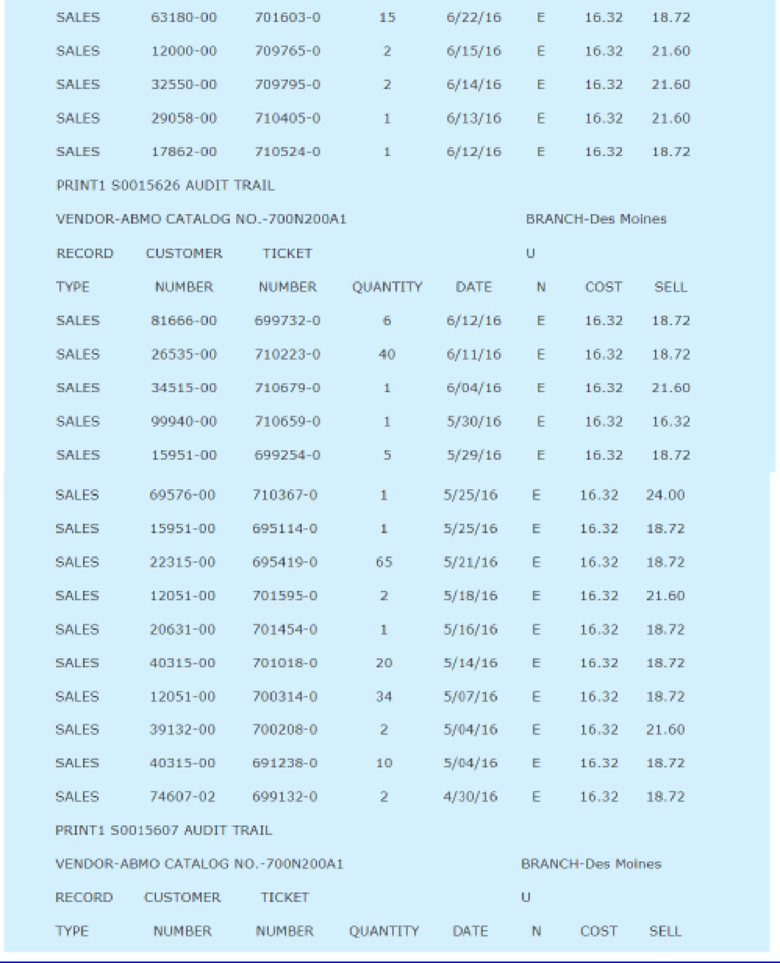

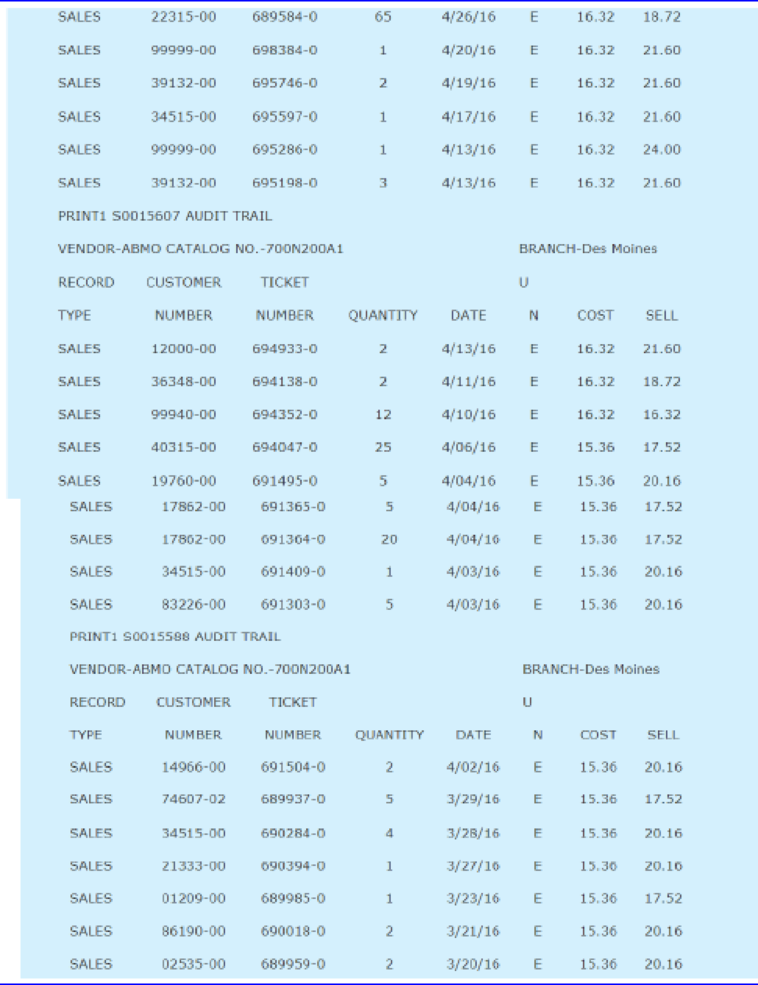

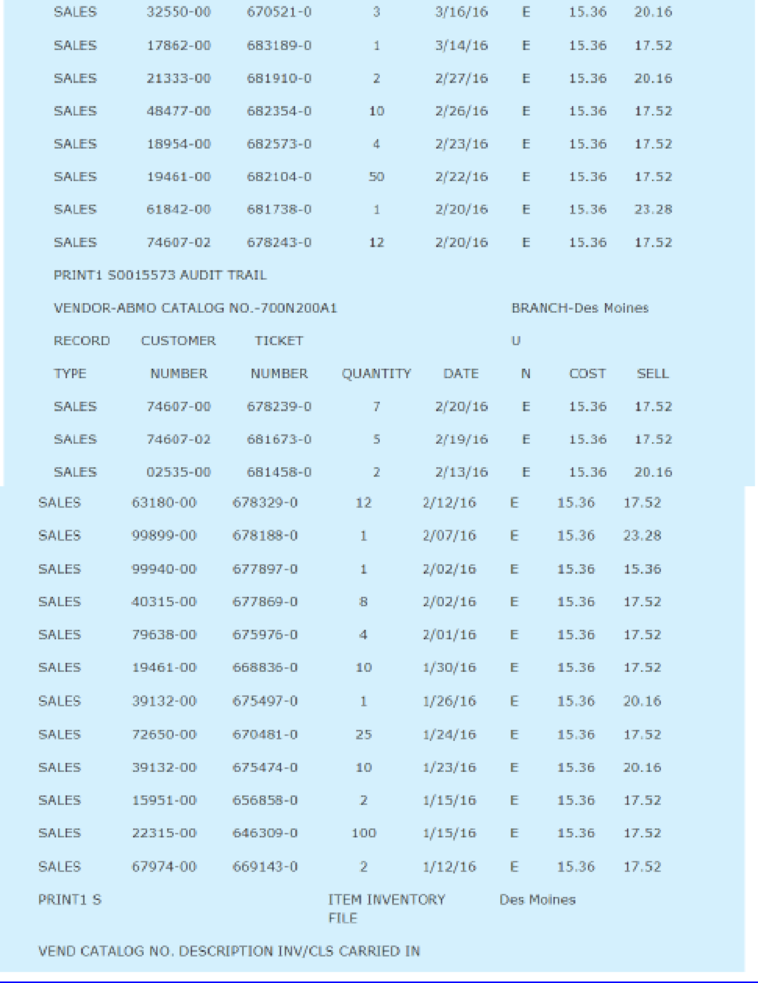

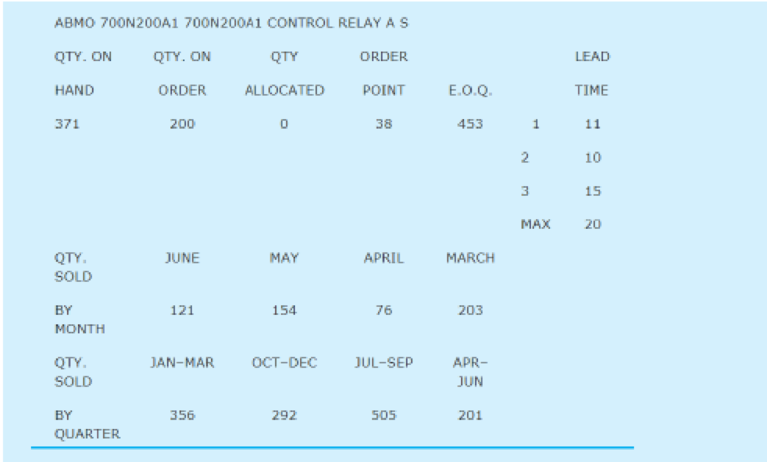

A demand history for a typical item is shown in Appendix 1.

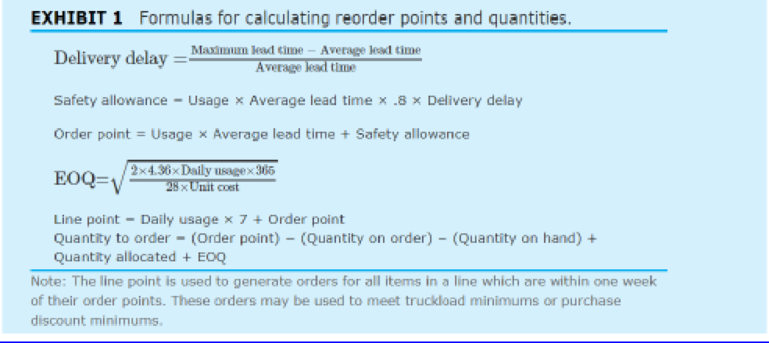

Henry was anxious to utilize the new system to calculate reorder points and order quantities, but he was unsure of the exact formulas to use. Using standard textbooks in the inventory field, Henry and Carl Byerly developed the formulas given in Exhibit 1. The EOQ formula utilizes a carrying cost of 28 percent and an ordering cost of $4.36 per order placed. These figures were based on past cost history at the company.

The formulas were programmed into the computer and tested on a pilot basis. For some Items the formulas seemed to work quite well, but for others they resulted in drastic departures from current practice and from common sense. For example, on one electrical box, the formulas would have ordered a two-year supply. Henry wanted to get the new software up as soon as possible, but he was not sure that the formulas would work properly. He wondered whether the formulas would meet the customer-service objectives of the business. Would they take advantage of truckload lots or purchase discounts whenever appropnate, and would the formulas result in reasonable inventory levels?

Discussion Questions

1. Design an inventory

2. Describe how the system you have designed will help the company meet customer-service and cost obiectives.

This case was prepared as a basis for class discussion, not to illustrate either effective or ineffective handling of an administrative situation.

Want to see the full answer?

Check out a sample textbook solution

Chapter CS Solutions

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

- At a recent board meeting of Co., a non-executive director suggested that the company’s remuneration committee should consider scrapping the company’s share option scheme, since the executives could be rewarded by the scheme even when they do not perform well. A second non-executive director had a view that, even when the executives act in ways which decrease the agency problem, they might not be rewarded by the share option scheme if the stock markets were in decline. REQUIRED: Explain the nature of the agency problem and discuss the use of share option schemes and performance-related pay as methods of reducing the agency problem in a stock-market listed company.arrow_forwardVulcan Radio Manufacturing Inc. ("Vulcan") is a well-known manufacturer of radio broadcast equipment. Vulcan employs Thor on a full-time basis as an engineering sales representative in Ontario. In addition to working for Vulcan, Thor performs independent professional engineering consulting services for radio broadcasters. Thor's business cards read Thor, Audio Consulting Engineering Services. Thor's independent services include technical analyses of broadcast systems. As part of these services, Thor often makes recommendations for the selection and purchase of broadcast equipment by broadcasters. Sometimes, Thor recommends Vulcan's equipment to clients. Using PEO's Codes of Ethics and Code of Conduct as your guide. What approvals, licences, etc. must Thor obtain in order to be legally allowed to provide such consulting professional engineering services? Assuming that Thor has all the necessary licences, what should Thor tell his regular employer and clients about this work?…arrow_forwardDuring the year ended December 31, 20X1, Greenacre Hospital received the following donations stated at their respective fair values: Essential specialized employee-type services from members of a religious group $100,000 Medical supplies restricted for indigent care from an association of physicians and used for such purpose in 20X1 30,000 How much total revenue from donations should Greenacre report in 20X1? A. $130,000 B. $100,000 C. $30,000 D. $0Varrow_forward

- The pain reliever medicine, Analgesia-T manufactured by CPC Company is a well-known analgesic that provides relief from pain and serves as a palliative to people worldwide. However, in the 1980s, several persons died after taking capsules of the well-known medicine. It was found out, that the medicines contained cyanide, a highly poisonous, white crystalline element accidentally mixed with the medicines because of factory defect. The sister company of CPC, the Jackson Company took the initiative and without delay, made steps to resolve the problem. It readily ordered the retrieval of the product from the market. Be that as it may, the company lost about $100M dollars by recalling more than 31 million bottles of Analgesia-T. The Jackson Company made all efforts to launch an information campaign in order to allay the fear of the consumers. The company ran a continuous media campaign and a toll-free customer care hotline. Millions of capsules were tested by reliable agencies and…arrow_forwardCorporate Social Responsibility has been defined as a “firm’s intelligent and objective concern for the welfare of society; such concern should entail a firm contributing to human betterment, by using its profit to address issues of concern to society and/or a firm to restraining from behaviour and activities that are harmful to society, no matter how immediately profitable such behaviour or activities might be”. Required: Describe the relationship between strategy and corporate social responsibility Explain how a firm’s cooperation in matters of taxes, bribery and corruption may constitute corporate social responsibilityarrow_forwardExplain the purpose of developing an OHS policy.arrow_forward

- 1. Cash flow concerns: The CEO of Mudge Paper Company, Jimmy Cricket, expressed concerns about tying up too much of the company's cash flow in the Bart's Office Supplies contract. This bias may have influenced his decision-making process when considering the extension of credit terms and credit limits. 2. Skepticism about Bart's payment history: The CEO's skepticism about Bart's payment history, specifically their tendency to pay invoices every 60 days instead of the agreed-upon 30 days, may have influenced his reluctance to extend credit terms and credit limits. 3. Fear of losing the Bart's account: The CEO may have been biased towards keeping the Bart's account, as they are a large and important customer for Mudge Paper Company. This bias may have influenced his decision-making process when negotiating the new sales contract with Bart's. 4. Over-reliance on Lauren Becall: The CEO may have placed too much trust in Lauren Becall, the top salesperson for Mudge Paper Company and the…arrow_forwardAdvice the management of Julida Investments Limited on how to undertake the distribution of their products to the market considering its a new entrant in the marketarrow_forwardand in some instances, located in remote areas. Due to their remote locations and small staffs, some offices do not have a compliance officer, and brokers working in these offices have sometimes had to take on the responsibility of hiring the branch manager. Some brokers work out of their homes and use their own personal e-mail to contact clients. Some branches only keep records in electronic form for six years. Which of the following is not a breach of the Code regarding Eagle Asset Managers? 1. Having the brokers in a remote office hire the branch manager. 2. Keeping records in electronic form for six years. 3. Communicating with clients via personal e-mail. 4. Not having a compliance officer. (Ctrl)arrow_forward

- Jack, a stockbroker, was an inexperienced in tax. He has sought the advice of an independent designated tax professional to advise him on tax planning and tax shelter that he needs. Simon, who is a designated accountant who specialized in those areas, advised Jack to invest in a number of multiple unit residential building (MURBs), a real estate investment project as tax shelter, by the conventional wisdom, were safe and conservative. When the value of MURBs fell during a decline in the real estate market, Jack lost heavily in his investment. Though the advice was perfectly sound at the time it was given, but unknown to Jack, Simon was also acting as adviser for developers in restructuring the MURBs and did not disclose that fact to Jack. In the context of breach of contract, is Jack liable for the loss of investment? In the context of breach of fiduciary duty, is Jack liable as well? Does ethics issue involve? Please state your reasons. Mr. Hunt, who has just retired, set up an…arrow_forwardJack, a stockbroker, was an inexperienced in tax. He has sought the advice of an independent designated tax professional to advise him on tax planning and tax shelter that he needs. Simon, who is a designated accountant who specialized in those areas, advised Jack to invest in a number of multiple unit residential building (MURBs), a real estate investment project as tax shelter, by the conventional wisdom, were safe and conservative. When the value of MURBs fell during a decline in the real estate market, Jack lost heavily in his investment. Though the advice was perfectly sound at the time it was given, but unknown to Jack, Simon was also acting as adviser for developers in restructuring the MURBs and did not disclose that fact to Jack. In the context of breach of contract, is Jack liable for the loss of investment? In the context of breach of fiduciary duty, is Jack liable as well? Does ethics issue involve? Please state your reasons. Mr. Hunt, who has just retired, set up an…arrow_forward82 Upon receipt of commission earned from a closed purchase loan, the mortgage loan originator sends the realtor a bottle of wine and a gift card to a local restaurant which of the the following regulations does this action violate? A) Violation of the Fair Housing Act B) Violation of the Truth in Lending Act (TILA) C) Violation of the Equal Credit Opportunity Act (ECOA) D) Violation of the Real Estate Settlement Procedures Act (RESPA)arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.