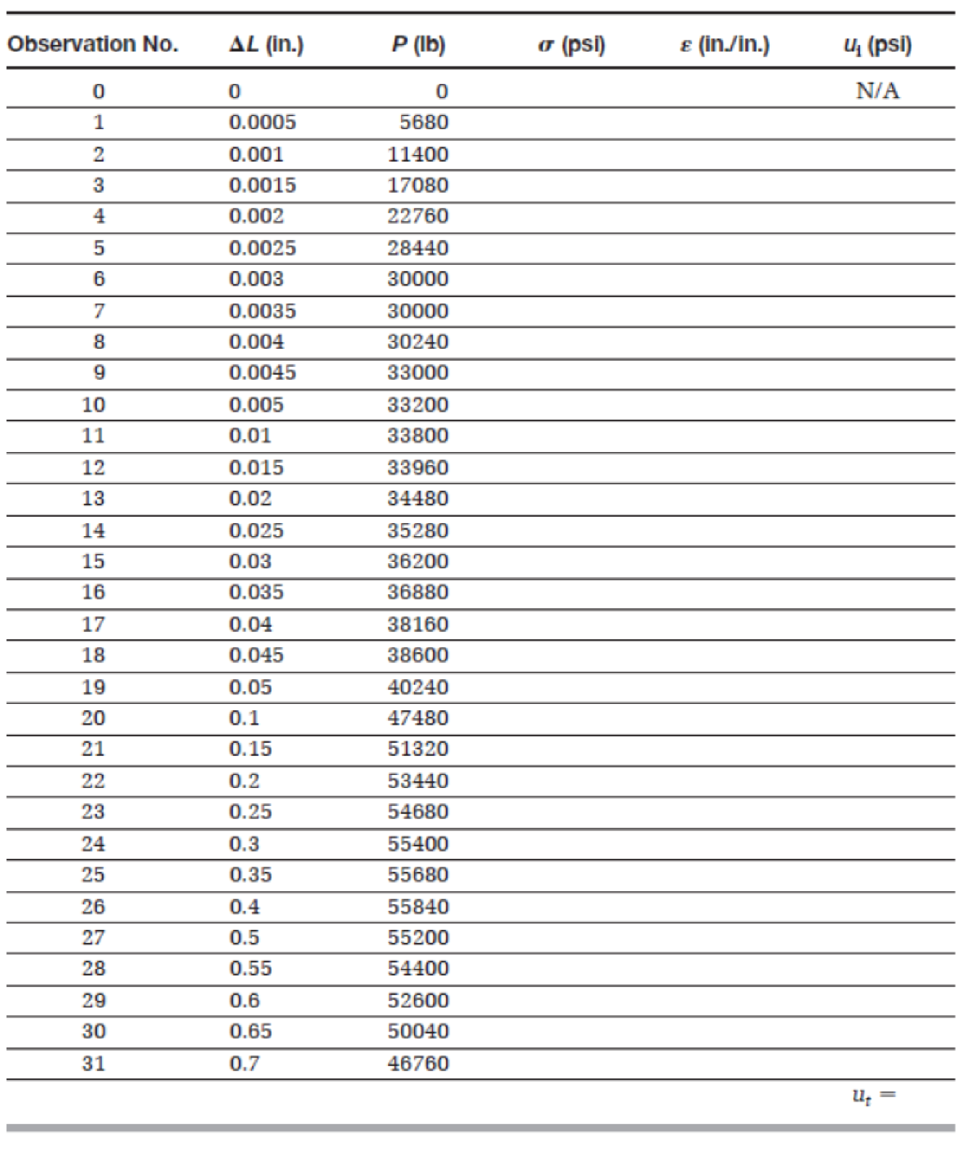

An engineering technician performed a tension test on an A36 mild steel specimen to fracture. The original cross-sectional area of the specimen is 0.25 in2 and the gauge length is 4.0 in. The information obtained from this experiment consists of applied tensile load (P) and increase in length (∆L) The results are tabulated in Table P3.44. Using a spreadsheet program, complete the table by calculating the engineering stress (σ) and the engineering strain (ε). Determine the toughness of the material (ut) by calculating the area under the stress-strain curve, namely,

where εf is the strain at fracture. The preceding integral can be approximated numerically using a trapezoidal integration technique:

TABLE P3.44

Want to see the full answer?

Check out a sample textbook solution

Chapter 3 Solutions

Materials for Civil and Construction Engineers (4th Edition)

- The data in Table 1.5.3 were obtained from a tensile test of a metal specimen with a rectangular cross section of 0.2011in.2 in area and a gage length (the length over which the elongation is measured) of 2.000 inches. The specimen was not loaded to failure. a. Generate a table of stress and strain values. b. Plot these values and draw a best-fit line to obtain a stress-strain curve. c. Determine the modulus of elasticity from the slope of the linear portion of the curve. d. Estimate the value of the proportional limit. e. Use the 0.2 offset method to determine the yield stress.arrow_forwardA tensile test was performed on a metal specimen having a circular cross section with a diameter of 1 2 inch. The gage length (the length over which the elongation is measured) is 2 inches. For a load 13.5 kips, the elongation was 4.6610 3 inches. If the load is assumed to be within the linear elastic rang: of the material, determine the modulus of elasticity.arrow_forwardA tensile test was performed on a metal specimen having a circular cross section with a diameter 0. 510 inch. For each increment of load applied, the strain was directly determined by means of a strain gage attached to the specimen. The results are, shown in Table: 1.5.1. a. Prepare a table of stress and strain. b. Plot these data to obtain a stress-strain curve. Do not connect the data points; draw a best-fit straight line through them. c. Determine the modulus of elasticity as the slope of the best-fit line.arrow_forward

- A high-yield-strength alloy steel bar with a rectangular cross section that has a width of 37.5 mm, a thickness of 6.25 mm, and a gauge length of 203 mm was tested in tension to rupture, according to ASTM E-8 method. The load and deformation data were as shown in Table Using a spreadsheet program, obtain the following:a. A plot of the stress–strain relationship. Label the axes and show units.b. A plot of the linear portion of the stress–strain relationship. Determine modulus of elasticity using the best-fit approach.c. Proportional limit.d. Yield stress.e. Ultimate strength.f. If the specimen is loaded to 155 kN only and then unloaded, what is the permanent deformation?g. In designing a typical structure made of this material, would you expect the stress applied in (f) safe? Why?arrow_forwardA tensile test specimen of aluminum alloy having a diameter of 0.5 in. and a gage length of 2 in. was tested to fracture. The complete stress-strain diagram for this specimen is shown below to the left. The small strain portion of this diagram has been enlarged (to the right) to show in more detail the linear portion of the stress-strain diagram. Determine (a) Young's modulus or modulus of elasticity (i.e., the slope of linear portion), (b) yield stress (using the so-called 0.2% offset method from the lecture notes), (c) yield strain (i.e., the strain corresponding to yield stress, not the 0.2%!), (d) ultimate strength (i.e., the peak in stress-strain diagram), (e) rupture stress (i.e., stress at breaking/failure), (f) rupture strain (i.e., the strain corresponding to rupture stress). 80 70 70 60 60 50 50 40 30 30 20 20 10 10 0.005 0.01 0.015 0.02 Strain (in/in) Strain (in/in) Stress (ksi) 0.015 - 0.03 - 0.12 - 0.135 - 0.15 Stress (ksi)arrow_forwardTesting a round steel alloy bar with a diameter of 15 mm and a gauge length of 250 mm produced the stress–strain relationship shown in Figure Determinea. the elastic modulusb. the proportional limitc. the yield strength at a strain offset of 0.002d. the tensile strengthe. the magnitude of the load required to produce an increase in length of 0.38 mmf. the final deformation, if the specimen is unloaded after being strained by the amount specified in (e)g. In designing a typical structure made of this material, would you expect the stress applied in (e) reasonable? Why?arrow_forward

- The following data were obtained from the tensile test of Aluminum alloy. The initial diameter of test specimen was 0.505 inch and gauge length was 2.0 inch. Plot the stress strain diagram and determine (a) Proportional Limit (b) Modulus of Elasticity (c) Yield Stress at 0.2% offset (d) Ultimate Stress and (e) Nominal Rupture Stress. Load (Ib) Elongation (in.) Load (Ib) Elongation (in.) 14000 0.020 2310 0.0022 14400 0.025 4640 0.0044 14 500 0.060 6950 0.0066 14 600 0.080 9 290 0.0088 14 800 0.100 11 600 0.0110 14 600 0.120 13 000 0.0150 13 600 Fracturearrow_forwardA steel specimen is tested in tension. The specimen is 25 mm wide by 12.5 mm thick in the test region. By monitoring the load dial of the testing machine, it was found that the specimen yielded at a load of 160 kN and fractured at 214 kN. a. Determine the tensile stress at yield and at fracture. b. If the original gauge length was 100 mm, estimate the gauge length when the specimen is stressed to 1/2 the yield stress.arrow_forward3. The distribution of stress in an aluminum machine component is given (in megapascals) by Ox = y + z? Oy = x + z Oz = 3x + y Txy = 3z2 Tyz = x Txz = %3D Calculate the state of strain at a point positioned at (1,2,4). Use E=70 GPa and v = 0.3arrow_forward

- The following data were obtained from the tensile test of Aluminum alloy. The initial diameter of test specimen was 0.505 inch and gauge length was 2.0 inch. Plot the stress strain diagram and determine (a) Proportional Limit (b) Modulus of Elasticity (c) Yield Stress at 0.2% offset (d) Ultimate Stress and (e) Nominal Rupture Stress. st 0.8 015 Load (Ib) Elongation (in.) Load (Ib) Elongation (in.) 14 000 0.020 2310 0.0022 14400 0.025 4640 0.0044 14 500 0.060 6950 0.0066 14 600 0.080 9 290 0.0088 14 800 0.100 11 600 13 000 0.0110 14 600 0.120 0.0150 13 600 Fracturearrow_forwardThe data shown in the table below were obtained from a tensile test of high-strength steel. The test specimen had a diameter of 13mm and a gage length of 50mm. At the fracture, the elongation between the gage marks was 3.0mm and the minimum diameter was 10.7mm. Plot the conventional stress-strain curve for the steel and determine the proportional limit, modulus of elasticity (i.e the slope of initial part of the stress-strain curve), yield stress at 0.1% offset, ultimate stress, percent elongation in 50mm, and percentage reduction in area Tensile-Test Data Load(kN) Elongation (mm) 5 0.005 10 0.015 30 0.048 50 0.084 60 0.099 64.5 0.109 67.0 0.119 68.0 0.137 69.0 0.160 70.0 0.229 72.0 0.259 76.0 0.330 84.0 0.584 92.0 0.853 100.0 1.288 112.0 2.814 113.0 Fracturearrow_forwardDuring a tensile test on a specimen of steel the following data was recorded, diameter of specimen 6.6mm gauge length of 50mm ,elongation of a load of 6.0 KN of 0.043mm. Reduction of area at failure of 45percent. Calculate the youngs modulus of elasticity ,the yield stress and the ultimate stressarrow_forward

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning