Concept explainers

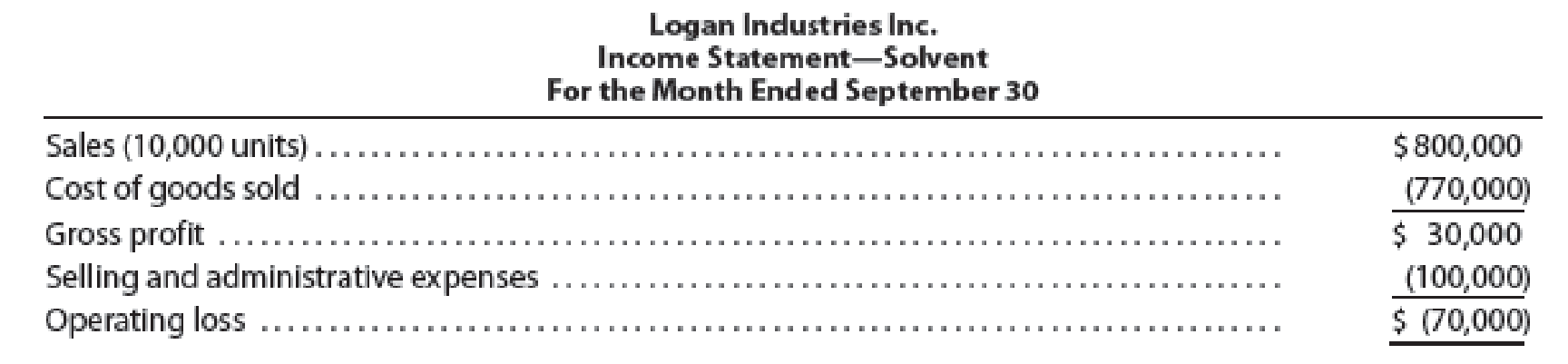

The demand for solvent, one of numerous products manufactured by Logan Industries Inc., has dropped sharply because of recent competition from a similar product. The company’s chemists are currently completing tests of various new formulas, and it is anticipated that the manufacture of a superior product can be started on November 1, one month in the future. No changes will be needed in the present production facilities to manufacture the new product because only the mixture of the various materials will be changed.

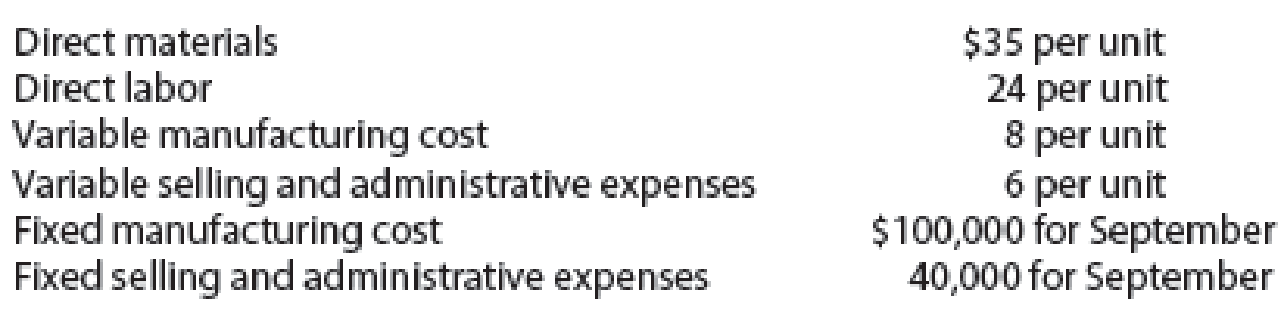

The controller has been asked by the president of the company for advice on whether to continue production during October or to suspend the manufacture of solvent until November 1. The following data have been assembled:

The production costs and selling and administrative expenses, based on production of 10,000 units in September, are as follows:

Sales for October are expected to drop about 40% below those of September. No significant changes are anticipated in the fixed costs or variable costs per unit. No extra costs will be incurred in discontinuing operations in the portion of the plant associated with solvent. The inventory of solvent at the beginning and end of October is not expected to be significant (material).

Instructions

- 1. Prepare an estimated income statement in absorption costing form for October for solvent, assuming that production continues during the month.

- 2. Prepare an estimated income statement in variable costing form for October for solvent, assuming that production continues during the month.

- 3. What would be the estimated operating loss if the solvent production were temporarily suspended for October?

- 4. What advice should you give to management?

Want to see the full answer?

Check out a sample textbook solution

Chapter 7 Solutions

Managerial Accounting

- Problem No. 3 The business assets of Glea Yares and Eunice Alico appear below: Yares Alico Cash P 10,000 P 25,000 Accounts Receivable 245,000 565,000 Inventories 122,000 260,000 Land 664,000 Building 938,000 Furniture and Fixtures Total 87,000 P1,128,000 36,000 P1,824,000 000,00 000,000 19 000,008 Account Payable Notes Payable P 178,000 200,000 Yare, Capital diw 750,000 P 245,000 345,000 adi to omen Alicol, Capital Total P1,128,000 1,234,000 P1,824,000 On March 5, 2025, Yares and Alico agreed to form a partnership contributing their assets and equities subject to the following adjustments: qining arboj su to nam a. Accounts receivable of P15,000 in Yares' books and P30,000 in Alico's are uncollectible. b. Inventories of P5,500 and P6,500 are worthless in Yares' and Alico's respective books. Required: 1. In the books of Yares, prepare the necessary journal entries: a. To record the adjustments to Yares' assets b. To close the books of Yares of viande no 251qgque oroa snemu ni 2. In the…arrow_forwardCritically evaluate the progress and challenges in achieving a single set of global accounting standards. Discuss the benefits and drawbacks of globalization in accounting, providing relevant examples. Critically assess the role of the Conceptual Framework in financial reporting and its influence on accounting theory and practice. Discuss how the qualitative characteristics outlined in the Conceptual Framework enhance financial reporting and contribute to decision-usefulness. Provide examples to support your analysis. a) Define research methodology in the context of accounting theory and discuss the importance of selecting appropriate research methodology. Evaluate the strengths and limitations of quantitative and qualitative approaches in accounting research. (10 marks) b) Assess the role of modern accounting theories in guiding research in accounting. Discuss how contemporary theories, such as stakeholder theory, legitimacy theory, and behavioral accounting theory, shape…arrow_forwardCritically evaluate the progress and challenges in achieving a single set of global accounting standards. Discuss the benefits and drawbacks of globalization in accounting, providing relevant examples. Critically assess the role of the Conceptual Framework in financial reporting and its influence on accounting theory and practice. Discuss how the qualitative characteristics outlined in the Conceptual Framework enhance financial reporting and contribute to decision-usefulness. Provide examples to support your analysis. a) Define research methodology in the context of accounting theory and discuss the importance of selecting appropriate research methodology. Evaluate the strengths and limitations of quantitative and qualitative approaches in accounting research. (10 marks) b) Assess the role of modern accounting theories in guiding research in accounting. Discuss how contemporary theories, such as stakeholder theory, legitimacy theory, and behavioral accounting theory, shape…arrow_forward

- Problem No. 2 The trial balance of Cleint Lumanao Nacho Supplies on February 10, 2025, before accepting Shila Tajonera as partner is shown as follows: Account Title Debit Credit Ato Cash reening smuo P 100,000 Accounts Receivable 250,000 Allowance for Uncollectible Accounts P 20,000 o Merchandise Inventory Equipment Accumulated Depreciation Accounts Payable Notes Payable 120,000 275,000 55,000 50,000 82,000 538,000 Lumanao, Capital Total P 745,000 P 745,000 Tajonera offered to invest cash to get a capital credit equal to one-half of Lumanao's capital after giving effect to the adjustments below. Lumanao accepted the offer. Valuation of some of the assets and liabilities of Lumanao, as agreed by the partners, are the following: • The merchandise is to be valued at P93,000. The accounts receivable is estimated to be 90% collectible. • The equipment is to be valued at P200,000. The partners also agreed that the name of the partnership will be Nacho Business. Required: 1. In the books of…arrow_forwardIf data is unclear in image or image blurr then comment.arrow_forwardSolve correctly without using aiarrow_forward

- Give solution correctly no chatgptarrow_forwardProblem No. 1 On January 1, 2025, Manuel Cruz and Sherimae Diasalo agreed to form a partnership that will manufacture and sell biscuits. The partnership agreement specified that Cruz is to invest cash of P1,000,000 and Diasalo is to contribute land and building to serve as the office and factory of the business. The following amounts are applicable to the property of Diasalo: Acquisition Cost Fair Market Value Land Building P1,000,000 500,000 P1,500,000 850,000 During the formation, it was found out that Cruz has accounts receivable amounting to P70,000 and the partners agreed that it will be assumed by the partnership. The name of the partnership will be Fita Pan. Required: 1. Prepare journal entry to record: a. The investment of Cruz to the partnership b. The investment of Diasalo to the partnershipood relay ni 000,219 2. Prepare the statement of financial position of the partnership as of January 1, 2025 Problem No. 2 The trial balance of Cleint Lumanao Nacho Supplies on February…arrow_forwardA company's stock price is $80, with earnings per share (EPS) of $10 and an expected growth rate of 12%.arrow_forward

- Kazama owns JKL Corporation stock with a basis of $20,000. He exchanges this for $24,000 of STU stock and $8,000 of STU securities as part of a tax-free reorganization. What is Kazama's basis in the STU stock?arrow_forwardKensington Textiles, Inc. manufactures customized tablecloths. An experienced worker can sew and embroider 10 tablecloths per hour. Due to the repetitive nature of the work, employees take a 10-minute break after every 10 tablecloths. Additionally, before starting each batch of 10 tablecloths, workers spend 8 minutes cleaning and setting up their sewing machines. Calculate the standard quantity of direct labor for one tablecloth.arrow_forwardSolvearrow_forward

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Principles of Cost AccountingAccountingISBN:9781305087408Author:Edward J. Vanderbeck, Maria R. MitchellPublisher:Cengage Learning

Principles of Cost AccountingAccountingISBN:9781305087408Author:Edward J. Vanderbeck, Maria R. MitchellPublisher:Cengage Learning