OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

7th Edition

ISBN: 9780077835439

Author: Roger G Schroeder, M. Johnny Rungtusanatham, Susan Meyer Goldstein

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 15, Problem 2P

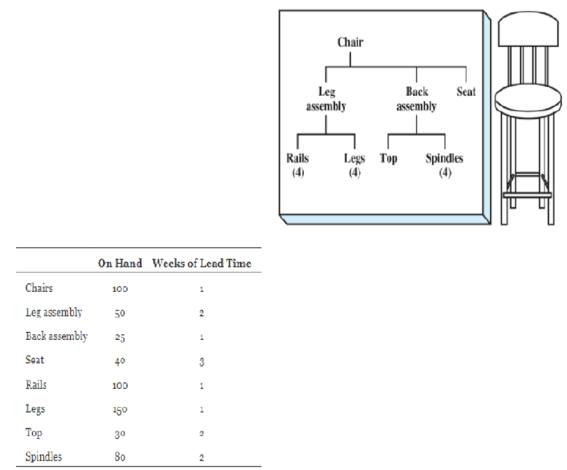

eXcel The Old Hickory Furniture Company manufactures chairs on the basis of the BOM shown below. At the present time, the inventories of parts and lead times are as follows:

The firm would like to produce 600 chairs in week 5 and 300 chairs in week 6.

- a. Develop a materials plan for all the parts.

- b. What actions should be taken now?

- c. Assume it takes one hour to assemble backs, one hour to assemble legs, and two hours to finish completed chairs. Total assembly time for all three types of assembly is limited to 1000 hours per week. Will this capacity constraint cause a bottleneck in assembly? If it does, what can be done?

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

Note:-

Do not provide handwritten solution. Maintain accuracy and quality in your answer. Take care of plagiarism.

Answer completely.

14.) A part structure, lead time (weeks), and on-hand quantities for product A are shown in Figure 14. From the information shown, generate:

a) An indented bell of material for product A.

b) Net requirements for each part to produce 10 As in week 8 using lot-for-lot.

Figure 14:

Figure below shows a partially completed MPS record for ball bearings.a. Develop the MPS for ball bearings.b. Four customer orders arrived in the following sequence:Order Quantity Week Desired1 500 42 400 53 300 14 300 7Assume that you must commit to the orders in the sequence of arrival and cannot change the desired shipping dates or your MPS. Which orders should you accept?

2

Chapter 15 Solutions

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

Ch. 15.7 - Prob. 1OLCh. 15 - Prob. 1DQCh. 15 - Prob. 2DQCh. 15 - With regard to inventory management, discuss the...Ch. 15 - Prob. 4DQCh. 15 - How much safety stock should be carried in a MRP...Ch. 15 - Prob. 6DQCh. 15 - Prob. 7DQCh. 15 - Prob. 8DQCh. 15 - Prob. 9DQ

Ch. 15 - Describe how MRP? concepts could be used for the...Ch. 15 - How are MRP and ERP related?Ch. 15 - The following information is given for a...Ch. 15 - eXcel The Old Hickory Furniture Company...Ch. 15 - Product A consists of subassemblies B and C....Ch. 15 - eXcel The BOM for product A given below Part on...Ch. 15 - The master scheduler in the ABC Widget Company is...Ch. 15 - A firm makes a basic scissors consisting of three...Ch. 15 - Prob. 7PCh. 15 - Prob. 8PCh. 15 - A small toy robot is assembled from sis parts: a...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- Dohini Manufacturing company had following 12 months of data on purchasing cost and number of purchase orders. Required: 1. Determine the high point and low point. 2. Calculate the variable rate for purchasing cost based on the number of purchase orders. (Round to nearest cent) 3. Calculate the fixed monthly cost of purchasing.(Round to nearest dollar). 4. Write the cost formula for the purchasing activity showing the fixed cost and the variable rate. 5. If Dohini manufacturing company estimates that next month will have 430 purchase orders, what is the total estimated purchasing cost for the that month?(Round to nearest dollar) 6. What if Dohini manufacturing wants to estimate purchasing cost for the coming year and expects 5340 purchase orders? What will estimated total purchasing cost be? What is the total fixed purchasing cost? Why doesn't equal the fixed cost calculated in Requirement 3?(Round to nearest dollar)arrow_forwardhello I need help with number 13 please and I need it only in excelarrow_forwardAs the production planner for Xiangling Hu Products, Inc., you have been given a bill of material for a bracket that is made up of a base, 2 springs, and 4 clamps. The base is assembled from 1 clamp and 1 housing. Each clamp has 1 handle and 2 castings. Each housing has 1 bearing and 2 shafts. There is no inventory on hand. Part 2 a) Design a product structure noting the quantities for each item and show the low-level coding. Match each number in the structure below with the corresponding item. Number Item I Spring Subscript left parenthesis 2 right parenthesisSpring(2) II Housing Subscript left parenthesis 1 right parenthesisHousing(1) III Casting Subscript left parenthesis 2 right parenthesisCasting(2) IV Shaft Subscript left parenthesis 2 right parenthesisShaft(2) Bracket Base(1) Clamp(1) Handle(1) Clamp(4) Bearing(1) Handle(1) Casting(2) IIIIIIIV Part 3 b) Determine the…arrow_forward

- Figure shows the BOMs for two products, A and B. Table 1 shows the MPS quantity start date for each one. Table 2 contains data from inventory records for items C, D, and E. There are no safety stock requirements for any of the items.a. Determine the material requirements plan for items C, D, and E for the next 8 weeks.b. What specific managerial actions are required in week 1?c. Suppose that a very important customer places an emergency order for a quantity of product A. To satisfy this order, a new MPS of 200 units of product A is now required in week 5. Determine the changes to the material requirements plan if this order is accepted and note any problems that you detect. MPS Quantity Start Dates Date Product 1 2 3 4 5 6 7 8 A 125 95 150 130 B 80 70 Inventory Record Data Item Data Category C D E Lot-sizing rule L4L POQ 1P = 32 FOQ = 800 Lead time 3 weeks 2 weeks 1 weeks Scheduled receipts 200 (week 2) None 800 (week 1) Beginning…arrow_forwardAs the production planner for Xiangling Hu Products, Inc., you have been given a bill of material for a bracket that is made up of a base, 2 springs, and 4 clamps. The base is assembled from 1 clamp and 2 housings. Each clamp has 1 handle and 1 casting. Each housing has 2 bearings and 1 shaft. There is no inventory on hand. A. Design a product structure noting the quantities for each item and show the low-level coding. B. Determine the gross quantities needed of each item if you are to assemble 50 brackets. C. Compute the net quantities if there are 25 of the base and 100 of the clamp in stock.arrow_forwardanswer in 30 minutes. answer only c partarrow_forward

- Brown and Brown Electronics manufactures a line of digital audiotape (DAT) players. The bill of materials, showing the number of each item required is shown below follows: F(2) C(1) I(2) F(2) H(1) I(2) Data for A: Gross requirement is 100 units on 9th week, Lead time is 2 weeks, Lot for lot A G(2) D(2) Data for C: Lead time is 1 weeks, Lot for lot Data for D: Lead time is 2 weeks, schedule receipt is 30 on 1st week, lot size 170 units Data for F: Lead time is 1 weeks, scheduled receipt is 60 on 1st week, on hand inventory is 15, lot for lot Data for G: Lead time is 1 weeks, scheduled receipt is 100 on 1st week, on hand inventory is 50, lot for lot Data for H: Lead time is 1 weeks, scheduled receipt is 50 on 1st week, lot size is 200 Data for I: Lead time is 1 weeks, scheduled receipt is 60 on 1st week, on hand inventory is 15, lot for lot Prepare an MRP schedule to satisfy the demand.arrow_forwardAn end item’s demand forecasts for the next 6 weeks are 30 units, followed by forecasts of 25 units for weeks 7 through 10. The current on-hand inventory is 60 units. The order policy is to produce in lots of 100. The booked customer orders for the item, starting with week 1, are 22, 30, 15, 11, 0, 0, 9, 0, 0, and 0 units. The lead time is 2 weeks.a. Develop an MPS for this end item.b. The marketing department has received six orders for this item in the following sequence:Order 1 is for 40 units to be delivered in period 3Order 2 is for 60 units to be delivered in period 4Order 3 is for 70 units to be delivered in period 6Order 4 is for 40 units to be delivered in period 3Order 5 is for 20 units to be delivered in period 5Order 6 is for 115 units to be delivered in period 9Assuming that the prospective MPS you developed in part (a) does not change, which orders would you be able to accept based on the available to promise (ATP)?arrow_forwardProduct M is made of two units of N and two of P. N is made of two units of R and four units of S. R is made of one unit of S and three units of T. P is made of two units of T and four units of U. a. Show the bill-of-materials (product structure tree). b. If 100 Ms are required, how many units of each component are needed? c. Show both a single-level parts list and an indented parts list.arrow_forward

- As the production planner for Xiangling Hu Products, Inc., you have been given a bill of material for a bracket that is made up of a base, 1 spring, and 3 clamps. The base is assembled from 2 clamp and 1 housing. Each clamp has 1 handle and 1 casting. Each housing has 2 bearing and 2 shaft. There is no inventory on hand. Part 2 a) Design a product structure noting the quantities for each item and show the low-level coding. Match each number in the structure below with the corresponding item. Number Item I Bracket II Spring Subscript left parenthesis 1 right parenthesis III Clamp Subscript left parenthesis 3 right parenthesis IV Bearing Subscript left parenthesis 2 rightarrow_forwardhelp please I need it to be done in excelarrow_forwardConsider the following product structure. If the demand for product A is 50 units, how many units of component D will be needed? Part 2 A. 200 B. 300 C. 50 D. 100 E. 150arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Inventory Management | Concepts, Examples and Solved Problems; Author: Dr. Bharatendra Rai;https://www.youtube.com/watch?v=2n9NLZTIlz8;License: Standard YouTube License, CC-BY