Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

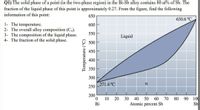

Transcribed Image Text:Q1) The solid phase of a point (in the two-phase region) in the Bi-Sb alloy contains 80 at% of Sb. The

fraction of the liquid phase of this point is approximately 0.27. From the figure, find the following

information of this point:

650

630.6 °C

1- The temperature.

2- The overall alloy composition (C.).

3- The composition of the liquid phase.

4- The fraction of the solid phase.

600

550

Liquid

O 500

450

400

350

300

271.4 °C

250

200

10

30

40

50

60

80

90

100

Bi

Atomic percent Sb

Sb

70

20

Temperature (°C)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- Consider the binary Magnesium-Lead phase diagram below.arrow_forward(a) Indicate hypooeutenic, hypereutenic ranges and eutenic composition in wt%Sn. Use the phase diagram below.arrow_forwardWhich of the following statements are true about the following phase diagram? Group of answer choices All three allotropes of iron exist at the same range of temperature and pressure. Iron vapor can exist at conditions of Earth's atmosphere. Solid iron can exist in three different crystal structures. Solid iron can exist in two different crystal structures. Liquid iron only exists at high pressure.arrow_forward

- Shown to the right is the solid-liquid phase behavior for mixtures of component A and component B at 1 atm. Use the phase diagram to answer the following questions. a) Specify the melting point of substance B at 1 atm b) What is the maximum composition (mole fraction) of component B that is possible for the mixture to exist in phase S2? At what temperature does this occur? c) 20mol of component A and 180mol of component B are mixed at 350°C and 1 atm. The mixture is cooled at constant pressure to 200°C. i) What phases are present at the final state? ii) What is the composition of each phase at the final state? iii) What is the number of moles of each phase at the final state?arrow_forward1 Al-Li Aerospace Alloys When a small amount of Li is added into Al to create an Al-Li alloy, the two elements typically do not mix homogeneously. Instead, most of the material is nearly-pure Al, while some small regions are Li-rich.¹ (These small regions are called precipitates and they are responsible for giving Al-Li alloys much better properties for aerospace applications relative to pure Al. We'll learn more about the alloying process and about precipitates later in the course.) The Li-rich regions have the chemical formula Al3Li and belong to the cubic crystal system.² In the unit cell, the Li atoms are located at 000, while the Al atoms are located at 110, 101, and 01121. (a) Draw the unit cell of Al3Li. (b) Which of the crystal structures from Callister Chapter 3 does this resemble? Why do we not call it that structure? (c) Given that the lattice parameter is 0.401 nm, what is the density of Al3Li?arrow_forward1. four processes. 2. Fill out the blanks by labeling the phase regions. 3. Identify the Indicate an in- termediate compound, if any. 3. Temperature (°C) 1600 1400 1200 1000 800 600 400 1538°C 0 (Fe) -1493°C 1394°C 912°C y, Austenite 1 2 0.16 5 0,022 a, Ferrite A N 2.14 Composition (at% C) 15 10 3 1147°C L4 3 4 Composition (wt% C) 4.30 727°C Sketch the microstructure at A, label phases, figure out compositions. 20 Cementite (Fe3C). 5 6 25 6.70arrow_forward

- A Pb-30% Sn alloy is cooled from 300°C to 50°C. a) What phases are present for this alloy at 50°C? b) How much of each phase is present at 50°C? c) What is the primary phase and its amount for this alloy at 50°C? Composition (at% Sn) 20 40 60 80 100 327°C 600 300 Liquid 500 232°C a + L 200 ß + L 400 183°C 18.3 61.9 97.8 300 100 a + B 200 100 40 60 80 100 (Pb) Composition (wt% Sn) (Sn) Temperature (°C) 20 Temperature (°F)arrow_forward100 atm 1 atm 0.118 atm 114 °C 184 °C 535 °C Temperature (not to scale) a.) Use the above generic phase diagram, clearly identify where you would find the following: Gas, Liquid, Solid, Triple Point, Draw arrows and label to indicate the six transitions (melting, freezing, sublimation, deposition, vaporization and condensation) b.) Based on the above phase diagram, what phase would you be in at a pressure of 50 atm and 300°C? c.) Based on the above phase diagram at what temperature in °C would vaporization occur under normal conditions? d.) If the pressure was 0.050 atm and 425°C, what phase would you be in? e.) If the pressure was 0.118 atm and temperature was 114°C, what phase(s) would you be in? f.) At approximately what temperature would the normal freezing point be in °C? g.) If the pressure was 0.105 atm and starting at a temperature of 32°C to 450°C what phase changes would occur (put in increasing temperature order). Pressure (not to scale)arrow_forwardAnswer part (iv) and (v)arrow_forward

- Use the Lead-Tin (Pb-Sn) phase diagram below to answer the following questions: Place the following microstructures in the correct order of formation for slowly cooling a 98 wt% Sn alloy from 300 °C to room temperature (point A to point B).arrow_forwardhelp pls A two-phase phase diagram is shown. Answer the following questions t -1300 1500+ Temperature 1100 0 34 54! 166 482 80 Composition of Ni % 20 What is the composition (in % Cu) of the solid phase corresponding to the red dot in between the solidus and liquidus lines in the phase diagram? Just write the number. Do not write the % symbol. Question 17 2.33 100 An alloy is being made with 66% Ni and 34% Cu. When it is cooled from 1500°C to the temperature corresponding to the red dot in the phase diagram, how many kg of liquid is present in the mixture?arrow_forwardHi i keep getting these wrongarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY