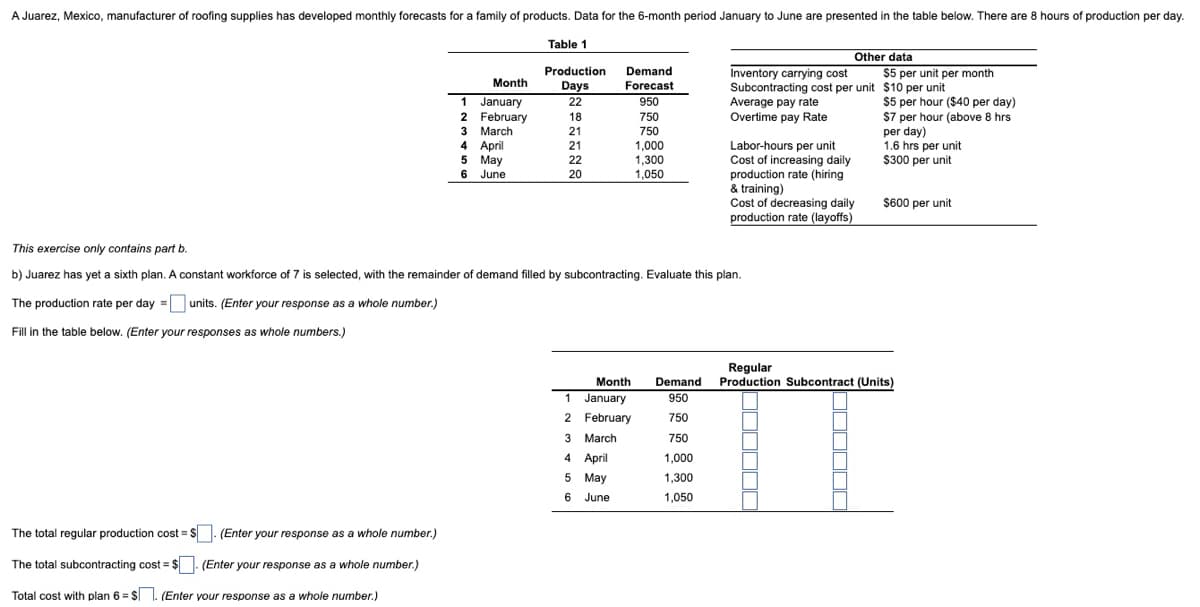

A Juarez, Mexico, manufacturer of roofing supplies has developed monthly forecasts for a family of products. Data for the 6-month period January to June are presented in the table below. There are 8 hours of production per day. Table 1 Other data Month 1 January 22 Production Demand Days Forecast 950 2 February 18 750 Inventory carrying cost Subcontracting cost per unit Average pay rate Overtime pay Rate 3 March 21 750 4 April 21 1,000 5 May 22 1,300 6 June 20 1,050 Labor-hours per unit Cost of increasing daily production rate (hiring & training) Cost of decreasing daily production rate (layoffs) $5 per unit per month $10 per unit $5 per hour ($40 per day) $7 per hour (above 8 hrs per day) 1.6 hrs per unit $300 per unit $600 per unit This exercise only contains part b. b) Juarez has yet a sixth plan. A constant workforce of 7 is selected, with the remainder of demand filled by subcontracting. Evaluate this plan. The production rate per day = ☐ units. (Enter your response as a whole number.) Fill in the table below. (Enter your responses as whole numbers.) The total regular production cost = $ (Enter your response as a whole number.) The total subcontracting cost = $. (Enter your response as a whole number.) Total cost with plan 6 = $. (Enter your response as a whole number.) Regular Month Demand Production Subcontract (Units) 1 January 950 2 February 750 3 March 750 4 April 1,000 5 May 1,300 6 June 1,050

A Juarez, Mexico, manufacturer of roofing supplies has developed monthly forecasts for a family of products. Data for the 6-month period January to June are presented in the table below. There are 8 hours of production per day. Table 1 Other data Month 1 January 22 Production Demand Days Forecast 950 2 February 18 750 Inventory carrying cost Subcontracting cost per unit Average pay rate Overtime pay Rate 3 March 21 750 4 April 21 1,000 5 May 22 1,300 6 June 20 1,050 Labor-hours per unit Cost of increasing daily production rate (hiring & training) Cost of decreasing daily production rate (layoffs) $5 per unit per month $10 per unit $5 per hour ($40 per day) $7 per hour (above 8 hrs per day) 1.6 hrs per unit $300 per unit $600 per unit This exercise only contains part b. b) Juarez has yet a sixth plan. A constant workforce of 7 is selected, with the remainder of demand filled by subcontracting. Evaluate this plan. The production rate per day = ☐ units. (Enter your response as a whole number.) Fill in the table below. (Enter your responses as whole numbers.) The total regular production cost = $ (Enter your response as a whole number.) The total subcontracting cost = $. (Enter your response as a whole number.) Total cost with plan 6 = $. (Enter your response as a whole number.) Regular Month Demand Production Subcontract (Units) 1 January 950 2 February 750 3 March 750 4 April 1,000 5 May 1,300 6 June 1,050

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter13: Regression And Forecasting Models

Section: Chapter Questions

Problem 34P: A small computer chip manufacturer wants to forecast monthly ozperating costs as a function of the...

Related questions

Question

Transcribed Image Text:A Juarez, Mexico, manufacturer of roofing supplies has developed monthly forecasts for a family of products. Data for the 6-month period January to June are presented in the table below. There are 8 hours of production per day.

Table 1

Other data

Month

1 January

22

Production Demand

Days Forecast

950

2 February

18

750

Inventory carrying cost

Subcontracting cost per unit

Average pay rate

Overtime pay Rate

3 March

21

750

4 April

21

1,000

5 May

22

1,300

6

June

20

1,050

Labor-hours per unit

Cost of increasing daily

production rate (hiring

& training)

Cost of decreasing daily

production rate (layoffs)

$5 per unit per month

$10 per unit

$5 per hour ($40 per day)

$7 per hour (above 8 hrs

per day)

1.6 hrs per unit

$300 per unit

$600 per unit

This exercise only contains part b.

b) Juarez has yet a sixth plan. A constant workforce of 7 is selected, with the remainder of demand filled by subcontracting. Evaluate this plan.

The production rate per day = ☐ units. (Enter your response as a whole number.)

Fill in the table below. (Enter your responses as whole numbers.)

The total regular production cost = $ (Enter your response as a whole number.)

The total subcontracting cost = $. (Enter your response as a whole number.)

Total cost with plan 6 = $. (Enter your response as a whole number.)

Regular

Month

Demand

Production Subcontract (Units)

1 January

950

2 February

750

3 March

750

4

April

1,000

5 May

1,300

6

June

1,050

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Contemporary Marketing

Marketing

ISBN:

9780357033777

Author:

Louis E. Boone, David L. Kurtz

Publisher:

Cengage Learning

Marketing

Marketing

ISBN:

9780357033791

Author:

Pride, William M

Publisher:

South Western Educational Publishing

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Contemporary Marketing

Marketing

ISBN:

9780357033777

Author:

Louis E. Boone, David L. Kurtz

Publisher:

Cengage Learning

Marketing

Marketing

ISBN:

9780357033791

Author:

Pride, William M

Publisher:

South Western Educational Publishing