Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

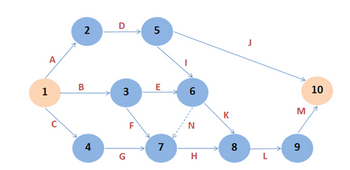

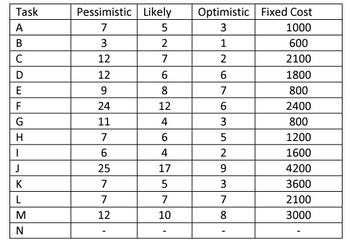

(Note: Task N is a dummy task. It must be included in the relationships, but its duration is 0. Be sure its duration is set to 0)

Please see attached charts and diagram.

Assign the following resources to the tasks. All resources will be full time. (Set the leveling to manual first).

| Task | Resource | Cost / Day |

| A | R1 | 200 |

| B | R2 | 300 |

| C | R3 | 300 |

| D | R4 | 300 |

| E | R2 | 300 |

| F | R4 | 300 |

| G | R1 | 200 |

| H | R5 | 200 |

| I | R6 | 400 |

| J | R5 | 200 |

| K | R1 | 200 |

| L | R3 | 300 |

| M | R2 | 300 |

| N | - | - |

2. Level if necessary. Then determine the new critical path and duration.

3. What is the total cost of the project (Fixed + Resource cost)? How much does the project need in the first, second, and third weeks?

Transcribed Image Text:A

2

D

5

B

1

3

E

6

K

LL

N

4

G

7

H

M

10

00

8

9

L

Transcribed Image Text:Task

Pessimistic

Likely

Optimistic Fixed Cost

A

7

5

3

1000

B

3

2

1

600

C

12

7

2

2100

D

12

6

6

1800

E

9

8

7

800

F

24

12

G

11

H

7

63

46

2400

800

5

1200

|

6

4

2

1600

J

25

17

9

4200

K

7

5

3

3600

L

7

7

7

2100

M

12

10

8

3000

N

-

-

-

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- mk t inces Given these observed times (in minutes) for four elements of a job, determine the observed time (OT) for each element. Note: The second element only occurs every other cycle. (Round your answers to 2 decimal places.) Element 2 3 Element 1 2 3 1 3.1 - 2.1 1.6 4 2 2.6 1.1 Click here for the Excel Data File CYCLE 3 3.1 - 2.1 3.1 2.6 1.6 Observed Time 4 3.1 1.1 2.1 1.6 5 3.1 2.1 1.6 3.1 1.1 2.1 1.6arrow_forward1. Develop a Work Breakdown Structure (WBS) identifying; a. Showing Summary tasks and b. Work Packages2. Stipulate your Completion Criteria for 5 of your most important tasks. Note: WBS in chart form or indented form. Give answers precisely.arrow_forwardOnly typed explanation otherwise leave itarrow_forward

- The City Commission of Nashville has decided to build a botanical garden and picnic area in the heart of the city for the recreation of its citizens. The precedence table for all the activities required to construct this area successfully is as follows: Code A B с D E F G H I Description Find location; determine resource requirements Requisition of lumber and sand Dig and grade Saw lumber into appropriate sizes Position lumber in correct locations Time (hrs) 20 60 100 30 20 10 20 10 30 Nail lumber together Put sand in and under the equipment Put dirt around the equipment Put grass all over the garden, landscape, paint Refer to the legend for the activity that corresponds to each code. Using the line drawing tool, draw a Gantt chart for activites E through I of the project. Immediate Predecessor(s) None A A B D, C E F F G, H A B C- D- E F G H- H 0 20 40 60 80 100 120 140 160 180 200 Q ✔arrow_forwardIn a network diagram, an activity:A) Is the largest unit of work effort consuming both time and resources that a project manager can schedule and control?B) Should always be something the company has had experience with. C) Is the smallest unit of work effort consuming both time and resources that a project manager can schedule and control?D) Must always have a single, precise estimate for the time duration.arrow_forwardTwo techniques for reducing rework expenses should be provided. Consider the need of progressive delivery across both tactics.arrow_forward

- a. Work Breakdown Structure (WBS): Develop a detailed work breakdown structure thatlists all the tasks required to launch the product or service. Organise the tasks into logicalphases and sub-phases.arrow_forwardFrancis Johnson’s plant needs to design an efficient assembly line to make a new product. The assembly line needs to produce 15 units per hour, and there is room for only four workstations. The tasks and the order in which they must be performed are shown in the following table. Tasks cannot be split, and it would be too expensive to duplicate any task. TASK TASK TIME (MINUTES) IMMEDIATE PREDECESSOR A 1 — B 2 — C 3 — D 1 A, B, C E 3 C F 2 E G 3 E What is the workstation cycle time required to produce 15 units per hour? Note: Round your answer to 1 decimal place. Balance the line to use the fewest possible workstations to meet the cycle time found in part (b). Use whatever method you feel is appropriate. What is the efficiency of your line balance, assuming the line operates at the cycle time from part (b)? Note: Round your answer to 1 decimal place.arrow_forwardHello, thanks greatly but why did you use maximum time duration and not shortest time rule in finding the time to make one ball? ( D5 - A14 = 120 SEC )arrow_forward

- The Action Toy Company has decided to manufacture a new train set, the production of which is broken into six steps. The demand for the train is 4,800 units per 40-hour workweek: Task Performance Time (seconds) Predecessors A 20 − B 30 A C 14 A D 15 A E 12 B, C F 27 D, E This exercise only contains parts b, c, d, e, and f. b) Given the demand, the cycle time for the production of the new train set = ____ (round your response to one decimal place). c) The theoretical minimum number of workstations is ___ d) Using the longest operation time rule, the assignment of tasks to workstations should be: (Hint: Number workstations sequentially in terms of precedence relationships and combine any applicable tasks.) e)How much is the total idle time per cycle for the process? ____ seconds f) What is…arrow_forwardThe Henry Street Mission uses volunteers to assemble carepackages for needy families during the holiday season. Themission would like to organize the work as efficiently as possible. A list of tasks, task times, and precedence re-quirements follows: a. If the mission wants to complete a care package every10 minutes, how many volunteers should be called in?Balance the line and calculate the efficiency. How manypackages can be assembled in a four-hour period?b. Suppose that volunteers are plentiful. Balance the lineto maximize output. What is the efficiency of the line? How many care packages can be assembled in a four-hour period?arrow_forward(Note: Task N is a dummy task. It must be included in the relationships, but its duration is 0. Be sure its duration is set to 0) Please see attached charts and diagram. Assign the following resources to the tasks. All resources will be full time. (Set the leveling to manual first). Task Resource Cost / Day A R1 200 B R2 300 C R3 300 D R4 300 E R2 300 F R4 300 G R1 200 H R5 200 I R6 400 J R5 200 K R1 200 L R3 300 M R2 300 N - - 1. Check for over-allocation. Which resources are over allocated? 2. Level if necessary. Then determine the new critical path and duration. 3. What is the total cost of the project (Fixed + Resource cost)? How much does the project need in the first, second, and third weeks?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.