Concept explainers

The demonstration of how rapidly Rayleigh’s method converges for the uniform-diameter solid shaft.

Answer to Problem 29P

The Rayleigh method for uniform diameter shaft is converging rapidly by using a static deflection beam equation.

Explanation of Solution

Write the expression for moment of inertia.

Here, the diameter of the shaft is

Write the expression for area of the shaft.

Write the expression for weight of the shaft.

Here, the specific weight is

Write the expression for influence coefficient.

Here, the length of the shaft is

Write the expression for deflection at point 1.

Write the expression for Rayleigh method.

Write the expression for Rayleigh method.

Write the expression for first critical speed.

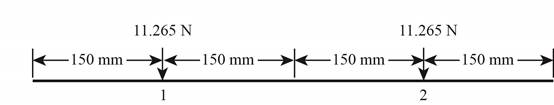

Draw the diagram for the two elements system.

Figure-(1)

The figure-(1) shows the required dimension.

Write the expression for the deflection at point 1 for two element.

Write the expression for the deflection at point 2 for two element.

Write the expression for Rayleigh method for two element.

Write the expression for Rayleigh method for two element.

Write the expression for first critical speed for two element.

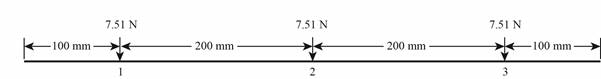

Draw the diagram for the three element system.

Figure-(2)

The Figure-(2) shows all the dimensions for the three elements.

Write the expression for the deflection at point 1 for three elements

Write the expression for the deflection at point 2 for three element.

Write the expression for the deflection at point 2 for three element.

Write the expression for Rayleigh method for three elements.

Write the expression for Rayleigh method for three elements.

Write the expression for first critical speed for three elements.

Conclusion:

Substitute

Substitute

Substitute

Substitute

Substitute

Calculate the square of the deflection at point 1 of element 1.

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Calculate the square of the deflection at point 1 of element 2.

Calculate the square of the deflection at point 2 of element 2.

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Calculate the square of the deflection at point 1 of element 3.

Calculate the square of the deflection at point 2 of element 3.

Calculate the square of the deflection at point 3 of element 3.

Substitute

Substitute

Substitute

Since the static bending equation is available, and satisfied the moment-free and deflection-free ends, so the convergence is rapid using a static deflection beam equation.

Thus, the Rayleigh method for uniform diameter shaft is converging rapidly by using a static deflection beam equation.

Want to see more full solutions like this?

Chapter 7 Solutions

Shigley's Mechanical Engineering Design (McGraw-Hill Series in Mechanical Engineering)

- mechaarrow_forward3. A flat annular steel flywheel of outer radius 0.5 m and inner radius 0.125 m with p = 7800 kN*s?/m* and v = 0.3 is to be shrunk fit around a solid steel shaft. The shrinking allowance is 0.1 mm. Both materials are the same type of steel with E = 210 GPa. Determine the RPM when the shrink fit loosens as a result of rotation.arrow_forwardplease help solvearrow_forward

- please help solvearrow_forwardFigure below shows a rotating shaft simply supported in ball bearings at A and D and loaded by a nonrotating orce Fof 6.8 kN. Using ASTM "minimum" strengths, estimate the life of the part. 6T td7 (a) Shaft drawing showing all dimensions in millimeters; all fillets 3-mm radius. The shaft rotates and the load is stationary; material is machined from AISI 1050 cold-drawn steel. (b) Bending moment diagram.arrow_forwardA shaft in torsion only is to transmit 2500 HP at 570 rpm with mild shock. Its material is AISI 1137 steel annealed. (a) What should be the diameter of a solid shaft? (b) If the shaft is hollow, Do = 2Di, what size is required? (c) What is the weight per foot of length of each of these shafts? Which is lighter? Use sp. weight = 0.286 Ibs/cu. in. (d) Which shaft is more rigid? Compute the torsional deflection of each shaft for a length of 10 ft.arrow_forward

- The rotating solid steel shaft is simply supported by bearings at points B and C and is driven by a gear (not shown) which meshes with the spur gear at D, which 250 mm has a 150 mm pitch diameter. The force F from the drive gear acts at a pressure angle of 20°. The shaft transmits a torque to point A of T = 340 N. m. The shaft 100 mm is machined from steel with S, = 420 MPa. Using a factor of safety of 2.5, determine the minimum allowable diameter of the 250 mm section of the shaft based on a static yield analysis using the distortion energy theory and maximum shear stress theory.arrow_forwardwith diameter d = 38 mm transmits 37 kW to a gear Calculate the required speed of rotation (number of at B. The allowable shear stress in the steel is 40 MPa. X7-3 A motor driving a solid circular steel shaft revolutions per minute) so that the shear stress in the shaft does not exceed the allowable limit. Motor d = 38 mm Barrow_forwardA hollow shaft made from AISI 4340 steel has an outer diameter D. of 4 in. and an inner diameter Di of 2.5 in. The shaft rotates at 46 rpm for one hour each day. It is supported by two bearings and loaded in the middle with a load W of 5500 lbf. The distance between the bearings Lis 78 in. The maximum tensile stress due to bending for this type of cyclic loading is calculated using the following equation: 8WLD, #(Dg – D{) What is the stress ratio for this type of cyclic loading? Would this shaft last for one year assuming a safety factor of 2?arrow_forward

- Design a hallow shaft (Diameter and length) that develops 80 kW of power while rotating at a speed of 4000 rpm. The design constrains are as under:The angle of twist not to exceed 0.200Shear stress is not to exceed 480 MN/m2The outer diameter is to be twice the inner diameter. The shaft length is to be three times the outer diameter. Modulus of rigidity = 79 GN/m2.arrow_forwardPlease don't provide handwritten solution .....arrow_forward(a) sigma max,min =+- 10.6 lodi Tau max = 5.35 kpsi (b) vb= -0.0102 in, wb= 0.0234 inarrow_forward

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning