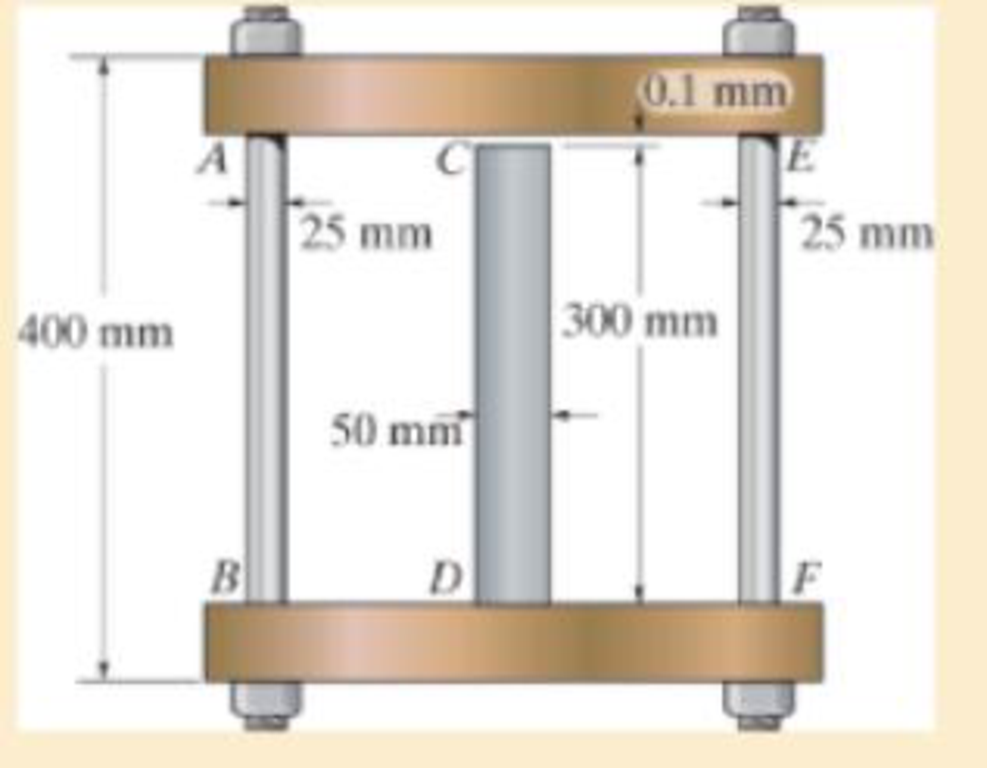

The assembly consists of two A992 steel bolts AB and EF and an 6061-T6 aluminum rod CD. When the temperature is at 30° C, the gap between the rod and rigid member AE is 0.1 mm Determine the normal stress developed in the bolts and the rod if the temperature rises to 130° C.

Assume BF is also rigid.

R4–1/2

The normal stress developed in the bolts and rod.

Answer to Problem 4.114RP

The normal stress developed in the bolts and rod are

Explanation of Solution

Given information:

The two bolts AB and EF are made of A992 steel.

The rod CD is made of 6061-T6 aluminum.

The Young’s modulus of the steel is

The Young’s modulus of the aluminum

The coefficient of thermal expansion of the steel

The coefficient of thermal expansion of the aluminum

The initial temperature

The finial temperature

The gap between the rod and rigid member AE is

The diameter of the bolts AB and EF

The diameter of the rod CD

The length of the bolts AB and EF

The length of the rod CD

Calculation:

Calculate the area of the bolts AB and EF

Substitute

Calculate the area of the rod CD

Substitute

Calculate the difference of temperature

Substitute

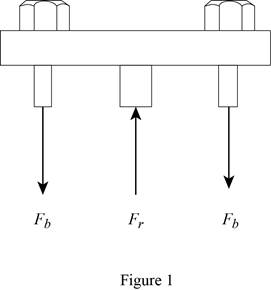

Show the free body diagram of the rigid cap as in Figure 1.

Refer Figure 1.

Calculate the vertical forces by applying the equation of equilibrium:

Sum of vertical forces is equal to 0.

Here,

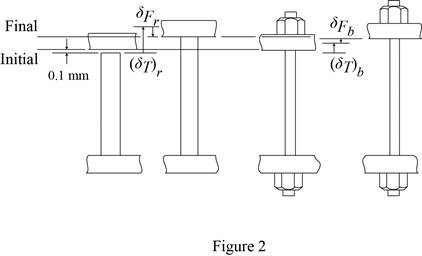

Show the initial and final position of the assembly as in Figure 2.

Refer Figure 2.

Here

The deformation is as follows:

Substitute

Calculate the force at the bolts AB and EF

Substitute

Calculate the force at the rod CD

Substitute

Calculate the normal stress developed in the bolts AB and EF

Substitute

Calculate the normal stress developed in the rod CD

Substitute

Hence, the normal stress developed in the bolts and rod are

Want to see more full solutions like this?

Chapter 4 Solutions

Mechanics of Materials

Additional Engineering Textbook Solutions

Automotive Technology: Principles, Diagnosis, And Service (6th Edition) (halderman Automotive Series)

INTERNATIONAL EDITION---Engineering Mechanics: Statics, 14th edition (SI unit)

Applied Fluid Mechanics (7th Edition)

Thinking Like an Engineer: An Active Learning Approach (3rd Edition)

Thinking Like an Engineer: An Active Learning Approach (4th Edition)

Statics and Mechanics of Materials (5th Edition)

- = Problem 8. The assembly has the diameters and material make-up indicated. If it fits securely between its fixed supports when the temperature is T₁ 70°F, determine the average normal stress in each material when the temperature reaches T₂ = 110°F. Also determine the longitudinal displacement of B and C after deformation. A 2014-T6 Aluminum 12 in. 4 ft B C 86100 Bronze 8 in. 6 ft 304 Stainless steel C 4 in. 3 ft Darrow_forwardThe bell-crank mechanism is in equilibrium for an applied load of F₁ = 11 kN applied at A. Assume a = 320mm, b = 170mm, c = 85mm, and 0 = 40%. Pin B is in a double-shear connection and has a diameter of 29 mm. The bell crank has a thickness of 23 mm. Determine (a) the shear stress in pin B. (b) the bearing stress in the bell crank at B. Bell crank F₂ Support bracket b MPa Answers: Tpin B = i Ob= i a MPaarrow_forwardThree metal rods are firmly attached to the walls and the middle rigid plate. Rod AB is made from stainless steel and rods CD and EF are made from 2014-T6 aluminum. If a balanced load is applied to the rigid plate, determine what the stresses are in the rods. Follow the sign convention that tensile stress is positive and compressive stress is negative. The parameter values are listed in the table above the figure. The moduli of the two materials are Ess = 193 GPa and Eal = 73.1 GPa parameter Li value units 450 mm L2 300 mm d₁ 40 mm d2 30 mm P 40 KN L1 A 1 P Cc 090 BY NO SA 2021 Cathy Zupke The stress in AB is σAB = P The stress in CD and EF: σCD = σEF= B MPa МРа E d₂ d2 LL F Darrow_forward

- The bell-crank mechanism is in equilibrium for an applied load of F1 = 10 kN applied at A. Assume a = 260mm, b = 170mm, c = 70mm, and 0 = 40°. Pin B is in a double-shear connection and has a diameter of 20 mm. The bell crank has a thickness of 28 mm. Determine (a) the shear stress in pin B. (b) the bearing stress in the bell crank at B. Bell crank F2 Support bracket B A a b Farrow_forwardAt a temperature of 20 °C there is a gap ∆ = 0.2 mm between the lower end of the brass bar and the slab rigid suspended from the two steel bars. Neglecting the mass of the slab, determine the stress in each bar when the temperature of the assembly rises to 100°C Answer: σsteel = 15.462MPa (t), σbronze= 20.615MPa(c),arrow_forwardDetermine the required gap (δ) so that the rails just touch one another when the temperature is increased from Ti = -20F and Tf = 100F Determine the stress in steel rails if the gap is δ = 0.5 in and the temperature is increased from Ti = -20F to Tf = 120F. NOTE: indicate the free body diagram.arrow_forward

- q4 last 4 digits is : 1004arrow_forwardThe d = 15-mm-diameter solid rod passes through a D = 20-mm-diameter hole in the support plate. When a load P is applied to the rod, the rod head rests on the support plate. The support plate has a thickness of b = 15 mm. The rod head has a diameter of a = 30 mm, and the head has a thickness of t = 9 mm. If the normal stress produced in the rod by load P is 200 MPa, determine (a) the bearing stress acting between the support plate and the rod head. (b) the average shear stress produced in the rod head. (c) the punching shear stress produced in the support plate by the rod head. Support Plate Hole diameter D Rod Head Calculate the cross-sectional area of the rod. Answer: Arodi mm²arrow_forwardThe d = 16-mm-diameter solid rod passes through a D = 21-mm-diameter hole in the support plate. When a load P is applied to the rod, the rod head rests on the support plate. The support plate has a thickness of b = 10 mm. The rod head has a diameter of a = 32 mm, and the head has a thickness of t = 10 mm. The shear stress in the rod head cannot exceed 135 MPa, the punching shear stress in the support plate cannot exceed 80 MPa, and the bearing stress between the rod head and the support plate cannot exceed 155 MPa. Determine the maximum value of Pmax that can be supported by the structure. Support Plate Rod Answer: Pmax= i Hole diameter D Head kN aarrow_forward

- The d = 15-mm-diameter solid rod passes through a D = 20-mm-diameter hole in the support plate. When a load P is applied to the rod, the rod head rests on the support plate. The support plate has a thickness of b = 10 mm. The rod head has a diameter of a = 30 mm, and the head has a thickness of t = 11 mm. The shear stress in the rod head cannot exceed 140 MPa, the punching shear stress in the support plate cannot exceed 105 MPa, and the bearing stress between the rod head and the support plate cannot exceed 130 MPa. Determine the maximum value of Pmax that can be supported by the structure. Support Plate Hole diameter D t Rod Answer: Pmax Mi -0 Head KN b→ aarrow_forwardThe d = 16-mm-diameter solid rod passes through a D = 21-mm-diameter hole in the support plate. When a load P is applied to the rod, the rod head rests on the support plate. The support plate has a thickness of b = 10 mm. The rod head has a diameter of a = 32 mm, and the head has a thickness of t = 10 mm. The shear stress in the rod head cannot exceed 140 MPa, the punching shear stress in the support plate cannot exceed 90 MPa, and the bearing stress between the rod head and the support plate cannot exceed 125 MPa. Determine the maximum value of Pmax that can be supported by the structure.arrow_forwardThe bell-crank mechanism is in equilibrium for an applied load of F1 = 17 kN applied at A. Assume a = 290mm, b = 120mm, c = 80mm, and e = 35°. Pin B is in a double-shear connection and has a diameter of 33 mm. The bell crank has a thickness of 36 mm. Determine (a) the shear stress in pin B. (b) the bearing stress in the bell crank at B. Bell crank F2 Support bracket A a Answers: Tpin B = MPa Ob = i MPaarrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY