Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

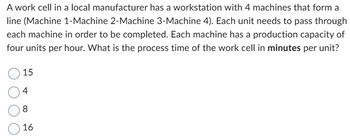

Transcribed Image Text:A work cell in a local manufacturer has a workstation with 4 machines that form a

line (Machine 1-Machine 2-Machine 3-Machine 4). Each unit needs to pass through

each machine in order to be completed. Each machine has a production capacity of

four units per hour. What is the process time of the work cell in minutes per unit?

15

4

8

16

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Students are going through a three-step process to obtain their ID cards. Each student will first spend 4 minutes at the (only one) registration desk. After that, he/she will visit one of three stations to have his/her picture taken, which takes 10 minutes on average. Finally, there is one machine that prints ID cards, and it takes 2 minutes to print a card. The demand rate is 12 students/hour. The process just completes serving a student. How long does it take to finish serving the following 10 students? Answers: a) 30min b) 40min c) 50min d) 60minarrow_forwardA process consists of 3 resources. Assume there exists unlimited demand for product, Resource 1 has processing time of 6 minutes per unit. Resource 2 has processing time of 4 minutes per unit. Resource 3 has processing time of 3 minutes per unit. All resources are staffed by 1 worker and each worker gets paid $ 12 per hour. What is the cost of direct labor ? How much idle time does worker at resource 3 have ? What is the average labor utilization ? Assume the demand rate is 20 units per hour, what is the Takt time ? Assume the demand rate is 20 units per hour, what is the Target manpower ? Show all formulas, calculations and results. Do on Canvasarrow_forwardConsider a production line with five stations. Station 1 can produce a unit in 9 minutes. Station 2 can produce a unit in 10 minutes. Station 3 has two Identical machines, each of which can process a unit in 12 minutes (each unit only needs to be processed on one of the two machines). Station 4 can produce a unit in 5 minutes. Station 5 can produce a unit in 8 minutes. a. which station is the bottleneck station?Explain with a diagram. b. What is the capacity of the production line ? c. Compute the throughput time.arrow_forward

- The following flow chart shows the entire manufacturing process at KD Manufacturing, which consists of six independent operations processes (i.e. sawing, sanding, drilling, reshaping, welding, and assembly). The entire process flow starts with the input of three different parts, Part I, Part II and Part III, each entering a different input line. Three parts meet later for the welding, whichever welding station is available (two identical welding stations work independently). After welding is completed, the product is sent to one of the three assembly stations (which are in parallel). The chart also shows the processing time per unit (in minutes) for each operation. Each of sawing, sanding, drilling and reshaping stations is handled by a different worker. Two workers handle welding, each at one welding station. Another three workers handle the assembly process independently, one at each assembly station. To improve the capacity of the entire manufacturing process, the manager decides to…arrow_forward. Bill's Barbershop has two barbers available to cut customers' hair. Both barbers provide roughly the same experience and skill, but one is just a little bit slower than the other. The process flow in Figure 6.90 shows that all customers go through Steps B1 and B2 and then can be served at either of the two barbers at Step B3. The process ends for all customers at Step B4. The numbers in parentheses indicate the minutes it takes that activity to process a customer. Figure 6.9 Process Flow for Bill's Barbershop B1 (10) B2 B3-a (15) B3-b (10) B4 (9) 1. On average, how long does it take a customer to complete this process? ›. What single activity is the bottleneck for the entire process? c. How many customers can this process serve in an hour?arrow_forwardFind the value of X in the following Flow Shop data consisting of 5 jobs which are to be processed on two machines M1 & M2 in that order. Jobs M1 M2 A 13 21 B 8 16 C 30 25 D 11 27 E 15 25 For the sequence using Johnson’s Rule, the Make span = Xarrow_forward

- An output of 720 units per shift (7.40 hours) is desired for a new processing system. The system requires product to pass through four stations where the work content at each station is 26 seconds. What is the required cycle time for such a system? How efficient is your system with the cycle time calculated? Station 3 changes and now requires 50 seconds to complete. What will need to be done to meet demand (assume only 7.40 hours are available)? What is the efficiency of the new system?arrow_forwardA work system has five serial stations that have process times of 5, 9, 4, 9, and 8. To complete processing, a unit needs to go through all stations. What is the process cycle time of the system?arrow_forwardA process of making chair is described as follows: Stage 1 Seat and back attached Stage 2 Legs attached The production speeds are 15 chairs per hour for Stage 1 and 30 chairs per hour for stage 2. The cycle time of the process is ______minutes. The flow time of the process is ______ minutes.arrow_forward

- Find the value of X in the following Flow Shop data consisting of 5 jobs which are to be processed on two machines M1 & M2 in that order. M2 Jobs A 7 B 5 C D E M1 5 2 1 4 13 3 6 3 For the sequence using Johnson's Rule, the Average Flow Time Xarrow_forwardChairs are made in a two step process with two resources. The processing time at the first resource is 30 minutes and for the second resource it is 23 minutes The first resource has 1 worker and the second resource has 1 worker. Instruction: Round your answer to three decimal places. What is the capacity of this process in terms of chairs per hour? chairs per hour 21arrow_forwardA production process at Kenneth Day Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). 7 units/hr 5 units/hr Assembly 0.8 units/hr Sawing Sanding Welding Assembly 2.1 units/hr 0.8 units/hr Drilling 2.5 units/hr Assembly 0.8 units/hr a) is the bottleneck. b) The bottleneck time is minutes per unit (round your response to two decimal places). c) The throughput time of the overall system is minutes (round your response to two decimal places).arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.