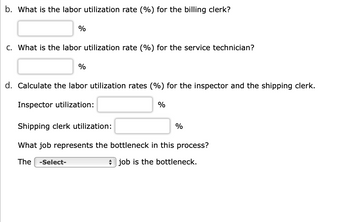

A medical equipment testing and calibration service is shown below. The customer usually brings the equipment to the service center. The service process requires service technicians to perform three process steps #1 to #3. Each technician is cross-trained so they can perform any of the three steps. The inspector does step #4 alone. After step #4, two parallel work activities are performed. That is, a shipping clerk packs the work (step #7), while simultaneously, a billing clerk prepares the invoice (step #5), and the customer is contacted by phone for pick-up (step #6). The average throughput is three equipment units per hour.

The table below shows the work content of the process steps, activity times in minutes per unit, shared and non-shared work activities, and the type of resource required. There are three service technicians on duty, one inspector, one billing clerk, and one shipping clerk.

| Activity Time | Activity | |

| Activity | (minutes) | Performed By |

| Start | - | |

| 1 | 7 | Service technician |

| 2 | 17 | Service technician |

| 3 | 26 | Service technician |

| 4 | 15 | Inspector |

| 5 | 3 | Billing clerk |

| 6 | 7 | Billing clerk |

| 7 | 25 | Shipping clerk |

| End | - |

Round your answers to the nearest whole number.

-

What is the service rate for the service technician?

minutes/unit

-

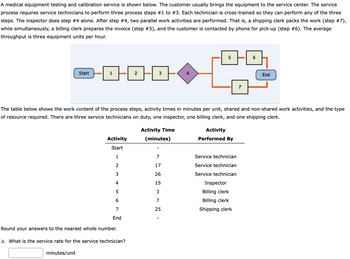

What is the labor utilization rate (%) for the billing clerk?

%

-

What is the labor utilization rate (%) for the service technician?

%

-

Calculate the labor utilization rates (%) for the inspector and the shipping clerk.

Inspector utilization: %

Shipping clerk utilization: %

What job represents the bottleneck in this process?

The job is the bottleneck.

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

- There are six wires which need to be attached to a circuit board. A robotic device will attach the wires. The wires can be attached in any order, and the production manager wishes to determine which order would be fastest for the robot to use. Use the multiplication rule of counting to determine the number of possible sequences of assembly that must be tested. (Hint: There are six choices for the first wire, five for the second wire, four for the third wire, etc.)arrow_forwardThese four elements make up what is often known as a machine cycle or process loop. I was wondering what others thought were the most important parts of machine cycles. Do you have to worry about changing various parts of a machine cycle? Is there a way to solve the problem of switching modules by adding another module?arrow_forwardA medical equipment testing and calibration service is shown below. The customer usually brings the equipment to the service center. The service process requires service technicians to perform three process steps #1 to #3. Each technician is cross-trained so they can perform any of the three steps. The inspector does step #4 alone. After step #4, two parallel work activities are performed. That is, a shipping clerk packs the work (step #7), while simultaneously, a billing clerk prepares the invoice (step #5), and the customer is contacted by phone for pick-up (step #6). The average throughput is three equipment units per hour. The table below shows the work content of the process steps, activity times in minutes per unit, shared and non-shared work activities, and the type of resource required. There are three service technicians on duty, one inspector, one billing clerk, and one shipping clerk. Activity Time Activity Activity (minutes) Performed By Start - 1 7 Service…arrow_forward

- A production process at Brianna Bryant Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). a) is the bottleneck. 1.8 units/hr Sawing minutes per unit (round your response to two decimal places). 5 units/hr Sanding Drilling 5 units/hr b) The bottleneck time is c) The throughput time of the overall system is minutes (round your response to two decimal places). d) If the firm operates 11 hours per day, 20 days per month, the monthly capacity of the manufacturing process is Welding 2.5 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr units (enter your response as a whole number). Qarrow_forwardA production process at Brianna Bryant Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). a) is the bottleneck. 1.8 units/hr Sawing minutes per unit (round your response to two decimal places). 5 units/hr Sanding Drilling 5 units/hr b) The bottleneck time is c) The throughput time of the overall system is minutes (round your response to two decimal places). d) If the firm operates 11 hours per day, 20 days per month, the monthly capacity of the manufacturing process is Welding 2.5 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr units (enter your response as a whole number). Qarrow_forwardThese four phases make up a machine cycle, which is also known as a process loop. What percentage of a machine's cycle time do you value the most? Should I be concerned about replacing parts of the machine cycle when they wear out? Is the problem of switching modules improved by adding a second module?arrow_forward

- These four steps make up what is called a machine cycle but is more often known as a process loop. When it comes to machine cycles, what factors do most people prioritise? Should I be concerned that I may have to replace machine cycle parts when they wear out? Is it feasible that doubling the number of modules available would make toggling between them easier?arrow_forwardPine Valley Furniture Pine Valley Furniture recently implemented a new internship program and has begun recruiting interns from nearby university campuses. As part of this program, interns have the opportunity to work alongside a systems analyst. This shadowing opportunity provides invaluable insights into the systems analysis and design process. Recently you were selected for a six-month internship at Pine Valley Furniture, and Jim Woo has been assigned as your supervisor. At an initial meeting with Jim Woo, he explains that Pine Valley Furniture is currently involved with two important systems development projects, the customer tracking system and WebStore. The purpose of the customer tracking system is to enable the PVF marketing group to track customer purchase activity and sales trends better. The WebStore project will help move the company into the twenty-first century by facilitating online furniture purchases, with an initial focus on corporate furniture buying. During your…arrow_forwardHP Computer's primary consumer business takes orders from customers for specific configurations of desktop and laptop computers. Customers must select from a certain model line of computer and choose from available parts, but within those constraints may customize the computer as they desire. Once the order is received, hp assembles the computer as ordered, and delivers it to the customer. What type of manufacturing process is described here?arrow_forward

- Ana Chavarria, front office manager, and Lorraine DeSantes, director of marketing and sales, have just returned from a computer conference at which they were able to look at the latest property management systems for hotels. Ana is enthusiastic about updating and adopting front office applications for reservations, registration, room status, posting, call accounting, checkout, and night audit. Lorraine is sure the marketing and sales applications will help her department be more efficient. Both realize the cost involved in obtaining modules for a property management system. 1.Whom should they include in developing a PMS adoption plan, and why? 2.What areas should they investigate?arrow_forwardA medical equipment testing and calibration service is shown below. The customer usually brings the equipment to the service center. The service process requires service technicians to perform three process steps #1 to #3. Each technician is cross-trained so they can perform any of the three steps. The inspector does step #4 alone. After step #4, two parallel work activities are performed. That is, a shipping clerk packs the work (step #7), while simultaneously, a billing clerk prepares the invoice (step #5), and the customer is contacted by phone for pick-up (step #6). The average throughput is three equipment units per hour. Round your answers to the nearest whole number. a. What is the service rate for the service technician? minutes/unit b. What is the labor utilization rate (%) for the billing clerk? 0-0-0-0 The table below shows the work content of the process steps, activity times in minutes per unit, shared and non-shared work activities, and the type of resource required.…arrow_forwardDreamInflate is a balloon manufacturing company. Balloon manufacturing consists of seven work stations, each performing a single step as indicated in the table below. There are five workers manned for the seven work stations as shown. Assume the workers are paid $15 per Worker Task Sequence Processing Time (secs/balloon) Task Dye production Electrocharging Dipping (Cold and Hot) Mortar Dipping Balloon inflation and delaltexing Vulcanization Inspection/Testing 1 30 w1 20 3 35 W2 25 W3 30 W4 6. 45 W5 7 40 hour. Each balloon pack is sold for $6 and has a variable cost of $1. The company has fixed costs of $200 per hour. There is more demand than the overall production system can provide. Based on the information provided, answer the following questions: • What is the cost of direct labor for balloons? • How much profit does DreamInflate make every hour? (note that the cost of direct labor is also a variable cost). What would the profit of DreamInflate be if the variable costs were 10…arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.