Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

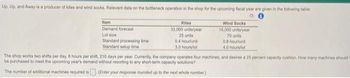

Transcribed Image Text:Up, Up, and Away is a producer of kites and wind socks. Relevant data on the bottleneck operation in the shop for the upcoming fiscal year are given in the following table

Wind Socks

10,000 units/year

Item

Demand forecast

Lot size

Standard processing time

Standard setup time

Kites

32,000 units/year

25 units

0.4 hourlunit

3.0 hours/lot

70 units

0.8 hour/unit

40 hours/fol

The shop works two shifts per day, 8 hours per shift, 210 days per year. Currently, the company operates four machines, and desires a 25 percent capacity cushion. How many machines should

be purchased to meet the upcoming year's demand without resorting to any short-term capacity solutions?

The number of additional machines required is (Enter your response rounded up to the next whole number)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- An output of 720 units per shift (7.40 hours) is desired for a new processing system. The system requires product to pass through four stations where the work content at each station is 26 seconds. What is the required cycle time for such a system? How efficient is your system with the cycle time calculated? Station 3 changes and now requires 50 seconds to complete. What will need to be done to meet demand (assume only 7.40 hours are available)? What is the efficiency of the new system?arrow_forwardManagement of Mittel Company would like to reduce the amount of time between when a customer places an order and when the order is shipped. For the first quarter of operations during the current year the following data were reported: Inspection time 0.7 days Wait time (from order to start of production) 16.9 days Process time 2.7 days Move time 1.0 days Queue time 4.3 days 1. Compute the throughput time. 2. Compute the manufacturing cycle efficiency (MCE) for the quarter. (Round your percentage answer to nearest whole percent.) 3. What percentage of the throughput time was spent in non–value-added activities? (Round your percentage answer to nearest whole percent.)arrow_forwardJB Bunt's fleet repair facility has the capacity to repair 800 trucks per month. However, due to scheduled maintenance of their equipment, management feels that they can repair no more than 600 trucks per month. Last month, two of the employees were absent several days each, and only 400 trucks were repaired. What is the utilization of the repair shop?arrow_forward

- Sintok Machines (SM) produces cast bronze valves for use in offshore oil platforms. Currently, SM produces 1600 valves per day. The 20 workers at SM work from 7 a.m. until 4 p.m., with 30 minutes off for lunch and a 15-minute break during the morning work session and another at the afternoon work session. SM is in a competitive industry and needs to increase productivity to stay competitive. They feel that a 20 % increase is needed. SM's management believes that the 20 % increase will not be possible without a change in working conditions, so they change work hours.The new schedule calls on workers to work from 8:00 a.m. until 5:00 p.m., during which workers can take one hour off at any time of their choosing. Obviously, the number of paid hours is the same as before, but production increases, perhaps because workers are given a bit more control over their workday. After this change, valve production increased to 1800 units per day.Question : A. For the hypothetical 20 percent increase…arrow_forward3. A bread-manufacturing line typically produces 150 loaves of bread during an 8-hour shift. On average, there are 30 loaves under processing in the line at any given time. What is the value and what is the L value? What is the average time it takes to produce a loaf of bread from the raw ingredients?arrow_forwardI need number 4 and 5 pleasearrow_forward

- Doog's Donuts produces five varieties of pastries, which are sold to a national grocery chain: muffins, donuts, cookies, cream puffs, and fritters. Assuming that Doog's operates a single shift for 1,800 hours per year. The processing time per unit, setup time per lot, the annual demand, and lot size are given in the table. Assume that the times given are for a work cell of four workers each. a. Complete the table given below. Pastry Muffins Donuts Cookies Cream puffs Fritters Demand Forecast (units/year) Required capacity 440,000 600,000 1,000,000 240,000 180,000 Processing Time (minutos/unit) 0.10 0.10 0.05 0.20 0.20 colls Lot Size Setup Time (f of pastries) (minutos/setup) 400 300 1,000 200 300 20 5 10 20 15 Total Processing Time minutes/year 0 Number of Batches per Year 0 Total Setup Time minutes/year b. Calculate the required capacity. (The required capacity should be in terms of the number of work cells needed) (Do not round intermediate calculations. Round up your answer to the…arrow_forwardPrevost Chemicals manufactures an industrial solvent at its only processing plant. A liquid chemical and labor are the two primary inputs. All other resources are included in manufacturing overhead. The plant never has any work-in-process or finished goods inventories. Information from the previous four periods of production follows: Chemical input (gallons) Labor input (hours) Solvent sales (gallons) Average price of chemical per gallon Average wage rate per hour Average sales price per gallon Manufacturing overhead (total) Required A Required B Required C Required: a. Compute the partial productivity measures for chemical for the four periods. b. Compute the partial productivity measures for labor for the four periods. c. Compute the total factor productivity for the four periods. Complete this question by entering your answers in the tabs below. Period Period 1 125,000 12,500 110,000 Period 1 $ 2.00 28.00 10.26 236,000 Compute the partial productivity measures for chemical for the…arrow_forwardL. Winston Martin (an allergist) has an excellent system for handling his regular patients who come in just for allergy injections. Patients arrive for an injection and fill out a name slip, which is then placed in an open slot that passes into another room staffed by one or two nurses. The specific injections for a patient are prepared, and the patient is called through a speaker system into the room to receive the injection. At certain times during the day, patient load drops and only one nurse is needed to administer the injections. Use Exhibit 712. Let's focus on the simpler case of the two-namely, when there is one nurse. Also, assume that patients arrive in a Poisson fashion and the service rate of the nurse is exponentially distributed. During this slower period, patients arrive with an interarrival time of approximately 3 minutes. It takes the nurse an average of 2.50 minutes to prepare the patients' serum and administer the injection. a. What is the average number of patients…arrow_forward

- The MacJunkin Company manufactures transmission parts. The current process uses 20 workers and produces 400 units per hour. You are considering changing the process with new manufacturing methods that increase output to 470 units per hour but will require 22 workers. Workers are paid at a rate of $15 per hour, and overhead is charged at 140% (or 1.4 times) labor costs. Finished switches sell for $80/unit. The details are as follows: Current Process New Process Output (Units/Hour) 400 470 Number of Workers 20 22 Material (Cost/Hour) $120 $150 These are the correct answers can you show me how to get these answers? A. What is the multifactor productivity ratio for the current process? 38.10 B. What is the multifactor productivity ratio for the new process? 39.92 Your answer is correct.arrow_forwardKnott's Industries manufactures standard and super premium backyard swing sets. Currently it has four identical swing-set-making machines, which are operated 275 days per year and 8 hours each day. A capacity cushion of 20 percent is desired. The following information is also known Annual Demand Standard Processing Time Average Lot Size Standard Setup Time per Lot a. Does Knott's have sufficient capacity to meet annual demand? Knott's does Standard Model 20,000 5min 50 30 min Super Premium Model 10,000 17 min 30 45 min have sufficient capacity to meet annual demand because 3 machines are needed. (Enter your response rounded up to the next whole number.) b. If Knott's was able to reduce the setup time for the Super Premium Model from 45 minutes to 30 minutes, would there be enough current capacity to produce 20,000 units of each type of swing set? If Knott's was able to reduce the setup time for the Super Premium Model from 45 minutes to 30 minutes, there would not be enough capacity to…arrow_forwardThere are four tasks performed in stations: mixing,, shaping, baking and packaging. Each cookie goes thru 1 of the 2 of shaping machines and 1 of the 3 baking ovens. Station 1 Mix 6.5 min/batch Station 2 shape 18 min/batch shape 10 min/batch Station 3 bake 17 min/batch bake 14 min/batch bake 35 min/batch Station 4 pack 9.8 min/batch 1. What is the Throughput time? 2. What is the Bottleneck time? 3. If factory operates 16 hours/day, 6 days/week, what is weekly capacity? 4. If upgrading some equipment to replace one of the existing operations. Which operation should be considered first?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.