FINANCIAL ACCOUNTING

10th Edition

ISBN: 9781259964947

Author: Libby

Publisher: MCG

expand_more

expand_more

format_list_bulleted

Question

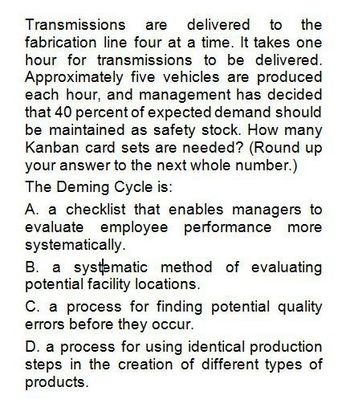

Transcribed Image Text:Transmissions are delivered to the

fabrication line four at a time. It takes one

hour for transmissions to be delivered.

Approximately five vehicles are produced

each hour, and management has decided

that 40 percent of expected demand should

be maintained as safety stock. How many

Kanban card sets are needed? (Round up

your answer to the next whole number.)

The Deming Cycle is:

A. a checklist that enables managers to

evaluate employee performance more

systematically.

B. a systematic method of evaluating

potential facility locations.

C. a process for finding potential quality

errors before they occur.

D. a process for using identical production

steps in the creation of different types of

products.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 3 images

Knowledge Booster

Similar questions

- Please show your work.arrow_forwardFiske Corporation manufactures a popular regional brand of kitchen utensils. The design and variety have been fairly constant over the last three years. The managers at Fiske are planning for some changes in the product line next year, but first they want to understand better the relation between activity and factory costs as experienced with the current products. Discussions with the plant supervisor suggest that overhead seems to vary with labor-hours, machine-hours, or both. The following data were collected from the last three years of operations: Quarter Machine-Hours Labor-Hours Factory costs 1 18,850 14,905 $ 3,388,671 2 18,590 15,477 3,425,136 3 17,480 16,720 3,617,144 4 19,240 15,983 3,573,240 5 21,280 17,501 3,812,284 6 19,630 17,369 3,777,312 7 19,240 15,290 3,531,726 8 18,850 14,366 3,369,102 9 18,460 15,994 3,512,487 10 20,670 16,995 3,730,734 11 17,550 14,278 3,135,315 12 18,460 19,244 3,723,786 Required: Use the high-low method to…arrow_forwardThe production department is proposing the purchase of an automatic insertion machine. It has identified three machines and has asked the accountant to analyze them to determine which one has the best average rate of return. Line Item Description Machine A Machine B Machine C Estimated average income $47,060.44 $72,961.50 $73,785.60 Average investment 336,146.00 243,205.00 491,904.00 a. Machine C b. Machine A c. Machines B and C have the same preferred average rate of return. d. Machine Barrow_forward

- Looking for cost savings in administrative areas, the vice-president for human resources at McMahon Corporation asked his assistant to collect data on the employee cafeterias in the four McMahon locations around the country. After two days, the assistant returned with the following data for the previous year. Mobile Lansing Spokane 23,500 Реcos Labor-hours 37,300 56,300 5,400 Meals served 114,000 222,000 79,000 13,900 Required: a. Compute the partial productivity measures for labor for the four locations. (Round your answers to 3 decimal places.) Partial Labor Location Productivity Mobile Ресos Spokane Lansingarrow_forwardDataSpan, Incorporated, automated its plant at the start of the current year and installed a flexible manufacturing system. The company is also evaluating its suppliers and moving toward Lean Production. Many adjustment problems have been encountered, including problems relating to performance measurement. After much study, the company has decided to use the performance measures below, and it has gathered data relating to these measures for the first four months of operations. Throughput time (days) Delivery cycle time (days) Manufacturing cycle efficiency (MCE) Percentage of on-time deliveries Total sales (units) 1 2 Month ? ? ? ? ? ? 91% 86% 3,460 3,312 Move time per unit Process time per unit Wait time per order before start of production Queue time per unit Inspection time per unit 3 ? ? ? 82% 3,143 4 Management has asked for your help in computing throughput time, delivery cycle time, and MCE. The following average times have been logged over the last four months: ? ? ? 78% 3,025…arrow_forwardYou work for a firm of management consultants that offers assistance to new businesses. One of your clients is Blossom Manufacturing, a company that manufactures a small, but vital, component for the specialized lighting industry. Blossom is a new company (and a new client for your employer) and you have been assigned the task of advising it of its options for financing its inventory during the first few months. The marketing experts have told you that Blossom should have at least three months of inventory on hand so it can meet all demands from its customers. The annual production of the Blossom component is projected to be 140,400 units. Annual direct labour and direct material costs together are estimated at $351,000 per year. Variable manufacturing costs are estimated to be $210,600 per year; fixed manufacturing costs are projected to be $585,000 per year. Fixed marketing and administration costs are estimated at $819,000 per year. These projections are all for the company's first…arrow_forward

- Please answer quick in 30 minutes. Prepare a comprehensive report to management highlighting three-year make-or-buy unit cost analysis and recommend appropriate action. What are the other non-cost variables that would be helpful in this analysis? As a manufacturing analyst, you are a member of a make-or-buy review team for electric components and work for a multinational company, TransAll Ltd. Your marketing group estimates the following volumes for a component required for motor assembly: Year 1; 300,000 units, Year 2: 500,000 units, Year 3: 200,000 units. A Chinese supplier has quoted the price as Mu(monetary unit) 0.10 per unit with 10 % price decrease per year for year 2 and 3 for the same component. . Shipping and handling costs are expected to be Mu 0.01 per unit for years 1 through 3. Additional inventory handling charges are Mu 0.005 per unit. In addition, purchasing costs are estimated at Mu 20 per purchase order with a purchase order being released every month for the…arrow_forwardAnswer with explanationarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning,

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning, Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning,

Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning, Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON

Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education

Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Accounting

Accounting

ISBN:9781337272094

Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.

Publisher:Cengage Learning,

Accounting Information Systems

Accounting

ISBN:9781337619202

Author:Hall, James A.

Publisher:Cengage Learning,

Horngren's Cost Accounting: A Managerial Emphasis...

Accounting

ISBN:9780134475585

Author:Srikant M. Datar, Madhav V. Rajan

Publisher:PEARSON

Intermediate Accounting

Accounting

ISBN:9781259722660

Author:J. David Spiceland, Mark W. Nelson, Wayne M Thomas

Publisher:McGraw-Hill Education

Financial and Managerial Accounting

Accounting

ISBN:9781259726705

Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting Principles

Publisher:McGraw-Hill Education