FINANCIAL ACCOUNTING

10th Edition

ISBN: 9781259964947

Author: Libby

Publisher: MCG

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

Transcribed Image Text:O

O

17 days

32 days

15 days

4 days

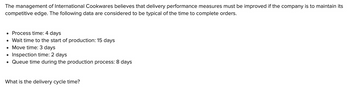

Transcribed Image Text:The management of International Cookwares believes that delivery performance measures must be improved if the company is to maintain its

competitive edge. The following data are considered to be typical of the time to complete orders.

• Process time: 4 days

• Wait time to the start of production: 15 days

• Move time: 3 days

●

Inspection time: 2 days

• Queue time during the production process: 8 days

What is the delivery cycle time?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Similar questions

- Could you please answer all the reuired fields correctly.arrow_forwardSHOW FORMULAS IN EXCELarrow_forwardKingcade Corporation keeps careful track of the time required to fill orders. Data concerning a particular order appear below: Wait time Process time Inspection time Move time Queue time The throughput time was: Multiple Choice O O 12.3 hours 27.4 hours 30.6 hours 3.2 hours Hours 18.3 1.1 0.1 2.0 9.1arrow_forward

- Wizard Corporation has analyzed their customer and order handling data for the past year and has determined the following costs: Order processing cost per order $7 Additional costs if order must be expedited (rushed) $10.00 Customer technical support calls (per call) $12 Relationship management costs (per customer per year) $1200 In addition to these costs, product costs amount to 75% of Sales. In the prior year, Wizard had the following experience with one of its customers, Chester Company: Sales $15,500 Number of orders 160 Percent of orders marked rush 70% Calls to technical support 80 Required: Calculate the profitability of the Chester Company account.arrow_forwardManagement of Mittel Company would like to reduce the amount of time between when a customer places an order and when the order is shipped. For the first quarter of operations during the current year the following data were reported: Inspection time Wait time (from order to start of production) 0.6 days 16.0 days 2.6 days 1.4 days 4.3 days Process time Move time Queue time Required: 1. Compute the throughput time. (Round your answer to 1 decimal place.) 2. Compute the manufacturing cycle efficiency (MCE) for the quarter. (Round your percentage answer to nearest whole percent.) 3. What percentage of the throughput time was spent in non-value-added activities? (Round your percentage answer to nearest whole percent.) 4. Compute the delivery cycle time. (Round your intermediate calculations and final answer to 1 decimal place.) 5. If by using Lean Production all queue time during production is eliminated, what will be the new MCE? (Do not round intermediate calculations. Round your…arrow_forwardManagement of Mittel Rhein AG of Köln, Germany, would like to reduce the amount of time between when a customer places an order and when the order is shipped. For the first quarter of operations during the current year the following data were reported: Inspection time Wait time (from order to start of production) Process time Move time Queue time Required: 0.6 days 17.1 days 3.1 days 1.2 days 4.5 days 1. Compute the throughput time. (Round your answer to 1 decimal place.) 2. Compute the manufacturing cycle efficiency (MCE) for the quarter. (Round your percentage answer to nearest whole percent.) 3. What percentage of the throughput time was spent in non-value-added activities? (Round your percentage answer to nearest whole percent.) 4. Compute the delivery cycle time. (Round your intermediate calculations and final answer to 1 decimal place.) 5. If by using Lean Production all queue time during production is eliminated, what will be the new MCE? (Round your percentage answer to 1…arrow_forward

- Swifty Corporation manufactures safes-large mobile safes, and large walk-in stationary bank safes. As part of its annual budgeting process, Swifty is analyzing the profitability of its two products. Part of this analysis involves estimating the amount of overhead to be assigned to each product line. The information shown below relates to overhead. Units planned for production Material moves per product line Purchase orders per product line Direct labor hours per product line (a) (1) One mobile safe $ (2) Your answer is correct. (b1) eTextbook and Media (a) One walk-in safe (b) The total estimated manufacturing overhead was $260,000. Under traditional costing (which assigns overhead on the basis of direct labor hours), what amount of manufacturing overhead costs are assigned to: (Round answers to 2 decimal places, e.g. 12.25.) One mobile safe $ One walk-in safe Mobile Safes Walk-in Safes $ 200 $ 300 450 800 416 50 3,536 200 The total estimated manufacturing overhead of $260,000 was…arrow_forwardSchurz Corporation's management reports that its average delivery cycle time is 29 days, its average throughput time is 13.0 days, its manufacturing cycle efficiency (MCE) is 0.20, its average move time is 0.6 day, and its average queue time is 3.0 days. Required: a. What is the wait time? (Round your answer to 1 decimal place.) b. What is the process time? (Round your answer to 1 decimal place.) c. What is the inspection time? (Round your intermediate calculations and final answer to 1 decimal place.) a b C Wait time Process time Inspection time days days daysarrow_forwardHello, I need help solving this accounting problem.arrow_forward

- Deep South Glass Company is exploring different prediction models that can be used to forecast machine maintenance costs. One independent variable under consideration is machine hours. Following are matching observations on machine maintenance costs and machine hours for the past six months: Month Machine hours Machine Maintenance costs 1 300 $20,000 400 $24,000 3 240 $17,000 4 370 $22,000 5 200 $13,000 6 225 $14,000 In a high-low model, which months' observations would be used to compute the model's parameters? 4 and 5 1 and 6 2 and 6 O 2 and 5arrow_forwardSimkin Corporation keeps careful track of the time required to fill orders. Data concerning a particular order appear below: Wait time Process time Inspection time Move time. Queue time The manufacturing cycle efficiency (MCE) was closest to: (Round your intermediate calculations to 1 decimal place.) Multiple Choice O 0.51 O 0.10 0.15 Hours 20.8 2.5 0.3 2.9 5.0 O 0.23arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning,

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning, Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning,

Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning, Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON

Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education

Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Accounting

Accounting

ISBN:9781337272094

Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.

Publisher:Cengage Learning,

Accounting Information Systems

Accounting

ISBN:9781337619202

Author:Hall, James A.

Publisher:Cengage Learning,

Horngren's Cost Accounting: A Managerial Emphasis...

Accounting

ISBN:9780134475585

Author:Srikant M. Datar, Madhav V. Rajan

Publisher:PEARSON

Intermediate Accounting

Accounting

ISBN:9781259722660

Author:J. David Spiceland, Mark W. Nelson, Wayne M Thomas

Publisher:McGraw-Hill Education

Financial and Managerial Accounting

Accounting

ISBN:9781259726705

Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting Principles

Publisher:McGraw-Hill Education