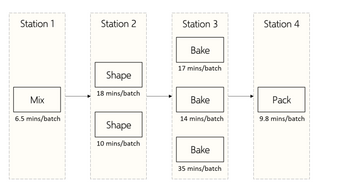

There are four tasks performed in stations: mixing,, shaping, baking and packaging. Each cookie goes thru 1 of the 2 of shaping machines and 1 of the 3 baking ovens.

Station 1 Mix 6.5 min/batch

Station 2 shape 18 min/batch shape 10 min/batch

Station 3 bake 17 min/batch bake 14 min/batch bake 35 min/batch

Station 4 pack 9.8 min/batch

1. What is the Throughput time?

2. What is the Bottleneck time?

3. If factory operates 16 hours/day, 6 days/week, what is weekly capacity?

4. If upgrading some equipment to replace one of the existing operations. Which operation should be considered first?

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

I am confused where your numbers are coming from. If look at the diagragm I attached.

The numbers used to calculate the thoroughput (15, 20 ,12) are not any numbers found in the diagragm

The miximg time is 6.5 min/batch not 15 min/dose as you indicated.

Bake times are 17, 14 and 35 min/batch not 10 min/batch as you indicated

Packing is 9.8 min/batch not 12 min/batch as you indicated.

When figuring out weekly capacity you multiple by 7 but problem indicates 6 days/week

It appears you are not solving this problem because you working with different numbers.

I am confused where your numbers are coming from. If look at the diagragm I attached.

The numbers used to calculate the thoroughput (15, 20 ,12) are not any numbers found in the diagragm

The miximg time is 6.5 min/batch not 15 min/dose as you indicated.

Bake times are 17, 14 and 35 min/batch not 10 min/batch as you indicated

Packing is 9.8 min/batch not 12 min/batch as you indicated.

When figuring out weekly capacity you multiple by 7 but problem indicates 6 days/week

It appears you are not solving this problem because you working with different numbers.

- In Richard Hall's framework, functional includes traditions of quality, customer service, human resources, or innovation. True Falsearrow_forwardManagement of Mittel Company would like to reduce the amount of time between when a customer places an order and when the order is shipped. For the first quarter of operations during the current year the following data were reported: Inspection time 0.7 days Wait time (from order to start of production) 16.9 days Process time 2.7 days Move time 1.0 days Queue time 4.3 days 1. Compute the throughput time. 2. Compute the manufacturing cycle efficiency (MCE) for the quarter. (Round your percentage answer to nearest whole percent.) 3. What percentage of the throughput time was spent in non–value-added activities? (Round your percentage answer to nearest whole percent.)arrow_forwardA production process at Brianna Bryant Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). a) is the bottleneck. 1.8 units/hr Sawing minutes per unit (round your response to two decimal places). 5 units/hr Sanding Drilling 5 units/hr b) The bottleneck time is c) The throughput time of the overall system is minutes (round your response to two decimal places). d) If the firm operates 11 hours per day, 20 days per month, the monthly capacity of the manufacturing process is Welding 2.5 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr units (enter your response as a whole number). Qarrow_forward

- A production process at Brianna Bryant Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). a) is the bottleneck. 1.8 units/hr Sawing minutes per unit (round your response to two decimal places). 5 units/hr Sanding Drilling 5 units/hr b) The bottleneck time is c) The throughput time of the overall system is minutes (round your response to two decimal places). d) If the firm operates 11 hours per day, 20 days per month, the monthly capacity of the manufacturing process is Welding 2.5 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr Assembly 0.8 units/hr units (enter your response as a whole number). Qarrow_forwardThe process of balancing an assembly line determines the ____ of the line. 1. Actual output 2. Efficiency 3. Utilizationarrow_forwardHow many units are needed to break even if eaxh completed unit has a value of $100?arrow_forward

- Please do fast ASAP fastarrow_forwardI need number 4 and 5 pleasearrow_forwardThe following table shows the process times in minutes (or minutes/unit - how many minutes to process one unit) of a six-station serial production line (1-2-3-4-5-6). Station 1 2 3 4 5 6 Which station(s) is (are) the bottleneck(s)? Station 2 Station 5 Stations 3 and 4 Stations 2 and 5 Process Time (minutes/unit) 8 11 7 7 11 4arrow_forward

- The recipe for a fruit smoothie requires 2 cups of fruit per 6 cups of yogurt to maintain a 1/3 ratio. While making the fruit smoothie, Suzy accidentally puts 3 cups of fruit into the pitcher. How many cups of yogurt should Suzy add to the pitcher to maintain the 1/3 ratio?arrow_forwardThese four steps make up what is called a machine cycle but is more often known as a process loop. When it comes to machine cycles, what factors do most people prioritise? Should I be concerned that I may have to replace machine cycle parts when they wear out? Is it feasible that doubling the number of modules available would make toggling between them easier?arrow_forwardIn Continuous manufacturing system, we need: Special purpose machines and Skilled labours ✔ Highly skilled labours and special machine tools General purpose machines and unskilled laborers. O Unskilled labours and semi automatic machinesarrow_forward

Understanding BusinessManagementISBN:9781259929434Author:William NickelsPublisher:McGraw-Hill Education

Understanding BusinessManagementISBN:9781259929434Author:William NickelsPublisher:McGraw-Hill Education Management (14th Edition)ManagementISBN:9780134527604Author:Stephen P. Robbins, Mary A. CoulterPublisher:PEARSON

Management (14th Edition)ManagementISBN:9780134527604Author:Stephen P. Robbins, Mary A. CoulterPublisher:PEARSON Spreadsheet Modeling & Decision Analysis: A Pract...ManagementISBN:9781305947412Author:Cliff RagsdalePublisher:Cengage Learning

Spreadsheet Modeling & Decision Analysis: A Pract...ManagementISBN:9781305947412Author:Cliff RagsdalePublisher:Cengage Learning Management Information Systems: Managing The Digi...ManagementISBN:9780135191798Author:Kenneth C. Laudon, Jane P. LaudonPublisher:PEARSON

Management Information Systems: Managing The Digi...ManagementISBN:9780135191798Author:Kenneth C. Laudon, Jane P. LaudonPublisher:PEARSON Business Essentials (12th Edition) (What's New in...ManagementISBN:9780134728391Author:Ronald J. Ebert, Ricky W. GriffinPublisher:PEARSON

Business Essentials (12th Edition) (What's New in...ManagementISBN:9780134728391Author:Ronald J. Ebert, Ricky W. GriffinPublisher:PEARSON Fundamentals of Management (10th Edition)ManagementISBN:9780134237473Author:Stephen P. Robbins, Mary A. Coulter, David A. De CenzoPublisher:PEARSON

Fundamentals of Management (10th Edition)ManagementISBN:9780134237473Author:Stephen P. Robbins, Mary A. Coulter, David A. De CenzoPublisher:PEARSON