Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

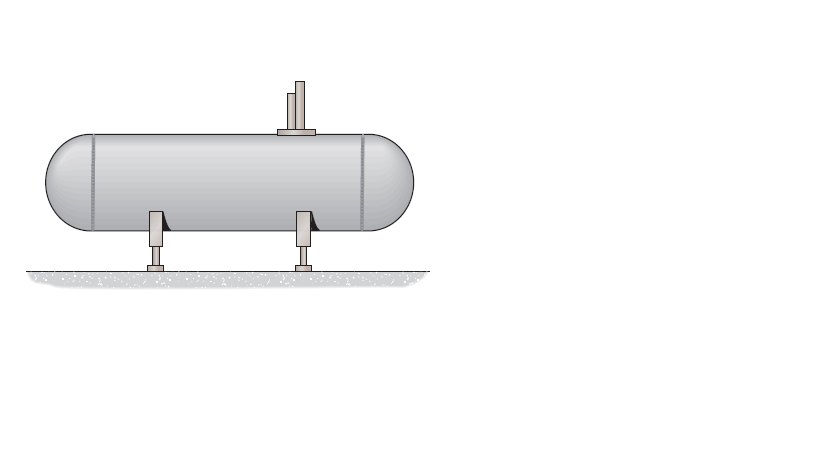

The gas tank is made from A-36 steel and has an inner diameter of 1.50 m. If the tank is designed to withstand a pressure of 5 MPa, determine the required minimum wall thickness to the nearest millimeter using (a) the maximum shear stress theory, and (b) maximum distortion energy theory. Apply a factor of safety of 1.5 against yielding.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 5 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The gas storage tank is fabricated by bolting together two half cylindrical thin shells and two hemispherical shells as shown. If the tank wall has a thickness of 50 mm for cylindrical and hemispherical shells, The bolts were installed as 40 bolts/meter. The tank and the 25 mm diameter bolts are made from material having an allowable normal stress of 150 MPa and 250 MPa, respectively. The tank has an inner diameter of 4 m. What is the maximum pressure that tank can contain.arrow_forwardA spherical gas tank has an inner radius of r = 1.5 m. If it is subjected to an internal pressure of p = 420 kPa, determine its minimum required thickness if the maximum normal stress is not to exceed 12 MPa.arrow_forwardigure 200 mm 400 mm 20 mm A Section a-a < F₁ 1 of 1 F₂ Determine the state of stress at point A on the cross section of the pipe assembly at section a -a. Take F₁ = 1540 N, F₂ = 1030 N (Figure 1) Express your answer to three significant figures and include the appropriate units. Enter negative value in the case of compression and positive in the case of tension. 4 σA= Part B μA Value Submit Request Answer (Tay) A = Find (Tzy) A- Express your answer to three significant figures and include the appropriate units. μA Units Value Units ? H ?arrow_forward

- At a temperature of 20 °C there is a gap ∆ = 0.2 mm between the lower end of the brass bar and the slab rigid suspended from the two steel bars. Neglecting the mass of the slab, determine the stress in each bar when the temperature of the assembly rises to 100°C Answer: σsteel = 15.462MPa (t), σbronze= 20.615MPa(c),arrow_forwardThe device is used to measure a change in temperature. Bars AB and CD are made of A-36 steel and 2014-T6 aluminum alloy respectively. When the temperature is at 65° F, ACE is in the horizontal position. Figure 1.5 in. -0.25 in. C 3 in. 1 of 1 اساساسا Part A Determine the vertical displacement of the pointer at E when the temperature rises to 160 ° F. (Figure 1) Express your answer with the appropriate units. SE = Value Submit Request Answer Provide Feedback Units ?arrow_forward3) A thin-walled cylindrical pressure vessel of diameter of 1.5 m is subjected to an internal pressure that varies continuously from p_min= 0.8MPa to p_max = 4 MPa. Determine the pressure vessel thickness, t, if the pressure vessel is made from steel with an ultimate strength S_u=400 MPa, a yield strength S_y=300MPa, and an endurance limit S_n-150MPa and a safety factor of two is desired. Use Modified Goodman and the maximum normal stress theory.arrow_forward

- please do not round it off until the final answerarrow_forwardThe pressure tank shown is fabricated from spirally-wrapped metal plates that are welded at the seams in the orientation shown. The tank has an inside diameter of 48 in. and a wall thickness of 0.375 in. Determine the largest allowable gage pressure if the allowable shear stress parallel to the weld is 3.10 ksi.arrow_forwardThe piston-cylinder assembly above has a wall thickness of 0.125" and an outer radius ro= 2 in. If the internal gauge pressure is 1.2 ksi, determine the maximum normal stress in the piston wall. 18 ksl O9 ksi 36 ksi N/A (this does not meet the criteria of a "thin-walled" pressure vessel)arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY