Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

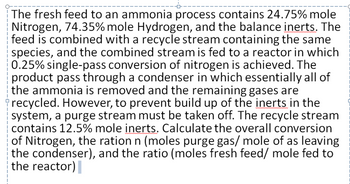

Transcribed Image Text:The fresh feed to an ammonia process contains 24.75% mole

Nitrogen, 74.35% mole Hydrogen, and the balance inerts. The

feed is combined with a recycle stream containing the same

species, and the combined stream is fed to a reactor in which

0.25% single-pass conversion of nitrogen is achieved. The

product pass through a condenser in which essentially all of

the ammonia is removed and the remaining gases are

recycled. However, to prevent build up of the inerts in the

system, a purge stream must be taken off. The recycle stream

contains 12.5% mole inerts. Calculate the overall conversion

of Nitrogen, the ration n (moles purge gas/ mole of as leaving

the condenser), and the ratio (moles fresh feed/ mole fed to

the reactor)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 2 images

Knowledge Booster

Similar questions

- 2. 100 mol/h of gaseous ethane is burned with excess air. The fuel is mixed with air before entering the furnace; fuel-air mixture is fed to the furnace at 25oC and 1 atm. All the ethane is consumed in the combustion reaction that occurs in the furnace. A cooling water jacket surrounding the furnace removes all of the heat generated by the combustion reaction. The stack gas leaves the furnace at 25oC and 1 atm and contains 5.32 mole% CO2, 1.60% CO, 7.32% O2 and the balance H2O and N2.a. Use Hess’s Law and the Heat of Combustion to calculate ∆??o (kJ/mol) for complete and incomplete combustion of ethane. b. Calculate the molar percentage of ethane in the fuel gas and the percentage excess air fed to the reactor.c. Calculate rate of heat transferred to the cooling water jacket in kW.arrow_forwardOne of the ways that benzene is produced on a large scale is the hydrodealkylation of toluene. C,H,CH; + H, C,H, + CH4 A stream of toluene is mixed with a recycle stream and enters a reactor along with a stream of pure hydrogen. The reaction products at 550 °C enter a condenser, where they are cooled to 41.0 °C. A vapor stream containing Y5CH, = 0.600 mol CH,/mol leaves the process, and a liquid stream containing x66 = 0.810 mol benzene/mol and x6 = 0.190 mol toluene/mol enters a distillation column. The distillate of the column leaves the process at n7 = 668.0 mol/h and contains y7h = 0.9000 mol benzene/mol and y7 = 0.1000 mol toluene/mol. The bottoms of the column contains X8b = 0.250 mol benzene/mol and xgt = 0.750 mol toluene/mol and is recycled back to the fresh feed. Hydrogen is fed into the process at ni = 1183 mol H,/h. This process is carried out at 760 mmHg. A n, mol/h mol H/mol YSH2 YSCH, mol CH_/mol Ysh mol b/mol Ys mol t/mol n̟ mol/h n, mol/h Condenser Улн, тol H/mol Усн,…arrow_forward11.7 mole dichloromethane (CH2Cl2) enter a reactor with 21.6 mole hydrogen (H2) and 37.5 mole oxygen (O2). The following reaction takes place: CH2Cl2 + H2 + 3/2 O2 → COCl2 + 2 H2O 6.4 mole of H2O are produced. Calculate the extent of the reaction.arrow_forward

- a process consists of two distillation columns. the composition of the feed to the first column is 30 mol% benzene, 30 mol% toluene, and 40 mol% xylene. the top stream of the first column does not contain xylene. the benzene content of the dome stream from the first column is 55 mol %. the bottoms stream from the second column has a flow of 100 mol/h and contains 15 mol% toluene and no benzene; while the top stream of the second column contains 50 mol % benzene. the upper stream flow of the first tower is twice the upper stream flow of the second tower. determine the molar flux of the fresh feed stream and the overhead stream leaving the first column.arrow_forwardFresh methanol (CH3OH) reactant is combined with recycled reactant and vaporized before being sent to a fixed-bed reactor. The reactor effluent is then cooled before being sent to the first of two distillation columns. DME (CH3)2O product is taken overhead from the first column. The second column separates the water from the unused methanol. The methanol is recycled back to the front end of the process, and the water is sent to wastewater treatment to remove trace amounts of organic compounds. Draw a block flow diagram for this process. The main reaction is 2CH3OH → (CH3)2O + H2Oarrow_forwardThe high-pressure synthesis of ammonia is known as the Haber process and can be written as: 3 H2 + N2 = 2 NH3 The reaction is an equilibrium one that results in a mixture of product (NH3) and unreacted reactants (H2 and N2). The production plant includes a splitter that separates perfectly ammonia from unreacted nitrogen and hydrogen. The unreacted N2 and H2 are recycled to the reactor with additional fresh feed. The fresh feed contains N2 and H2 in the stoichiometric ratio. The extent of reaction depends on the operating conditions: at 600 K and 300 bar and when the feed to the reactor is 80 moles/hour, the moles of NH3 generated in the reactor per unit of time are 34.50 moles/hour. A schematic of the process is given below. Determine the fluxes and compositions of all streams (Total molar flow rate (mol/h), Molar flow rate H2 (mol/h), Molar flow rate N2 (mol/h), Molar flow rate NH3 (mol/h)).arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The