Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

first 2 most important

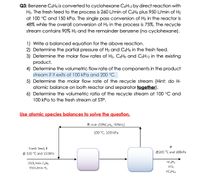

Transcribed Image Text:Q3: Benzene CaHs is converted to cyclohexane CsH12 by direct reaction with

H2. The fresh feed to the process is 260 L/min of CoHs plus 950 L/min of H2

at 100 °C and 150 kPa. The single pass conversion of H2 in the reactor is

48% while the overall conversion of Hz in the process is 75%. The recycle

stream contains 90% H2 and the remainder benzene (no cyclohexane).

1) Write a balanced equation for the above reaction.

2) Determine the partial pressure of H2 and CoHs in the fresh feed.

3) Determine the molar flow rates of H2. CsHo and C&H12 in the existing

product.

4) Determine the volumetric flow rate of the components in the product

stream if it exits at 100 kPa and 200 °C.

5) Determine the molar flow rate of the recycle stream (Hint: do H-

atomic balance on both reactor and separator together).

6) Determine the volumetric ratio of the recycle stream at 100 °C and

100 kPa to the fresh stream at STP.

Use atomic species balances to solve the question.

R male (10%CH, 90%H;)

100 °C, 100 kPa

Fresh feed, F

@ 200 °C and 100kPa

@ 100 °C and 150kPa

26OL/min CH,

950L/min H;

nH2

nC;H12

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Derivation of the general equation for interpolation: develop from scratch the equation interpolation you need to developarrow_forwardWhat types of the boundary conditions we have?arrow_forwardGive a table showing classification of mass transfer operations used in Chemical industries with phases of contactarrow_forward

- For which set of crystallographic planes will a first-order diffraction peak occur at a diffraction angle of 44.53° for FCC nickel (Ni) when monochromatic radiation having a wavelength of 0.1542 nm is used? The atomic radius for Ni is 0.1246 nm. 1) ( eTextbook and Media Assistance Usedarrow_forwardHelp mearrow_forwardQ4/ Reduce the following system by using Masson's method: G7 H8 G5 G6 G4 G₁ G2 G3 H4 H5 H6 H₁ H₂ H3 G8 H7arrow_forward

- Give a brief description of the use of hydrostatic pressure in level measurement. List the main advantages and disadvantages. What is the formula used to deduce level from pressure?arrow_forwardXi = уір ресто drive to get this equation lap = when УА + Ув YA Ус PA(T) PALT) PACT)arrow_forwardwhat is the number of electrons that an ion of iodine would most commonly have?arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The