Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Topic Video

Question

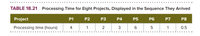

Given the projects displayed in Table 18.21, if FCFS is used to sequence the jobs, what

is the average flow time of the projects (in hours)?

Transcribed Image Text:TABLE 18.21 Processing Time for Eight Projects, Displayed in the Sequence They Arrived

Project

P1

P2

P3

P4

P5

P6

P7

P8

Processing time (hours)

4

2

3

6

5

1

0.5

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- Eight jobs have arrived in the following order: Job Processing Time Due Date 1 7 23 2 3 9 3 5 8 4 2 11 5 6 16 6 9 18 7 14 40 8 4 31 Find and compare the performance measures for the following sequencing rules using the Excel Sequencing template. Round your answers to two decimal places. Process in the order they have arrived Flow Time Lateness Tardiness Averagearrow_forwardK Courtney is a programmer receiving requests each week to analyze a large data base. Five jobs were on her desk Monday morning, and she must decide in what order to write the code. Assume that all jobs arrived today (day 1 and hour 1), in the order shown below. Courtney has assigned the number of hours required to do the coding as noted. Note that Courtney works an 8-hour day and today is a work day. JOB A C D E DUE DATE (HOURS HENCE) 10 16 14 36 26 DURATION (HOURS REQUIRED) 6 3758 a) Sequence the jobs according to EDD. According to the EDD rule, the sequence of jobs should be A, C, B, E, D b) What is the average completion (flow) time? The average completion (flow) time is days (round your response to one decimal place).arrow_forwardCourtney is a programmer receiving requests each week to analyze a large data base. Five jobs were on her desk Monday morning, and she must decide in what order to write the code. Assume that all jobs arrived today (day 1 and hour 1), in the order shown below. Courtney has assigned the number of hours required to do the coding as noted. Note that Courtney works an 8-hour day and today is a work day. DURATION (HOURS REQUIRED) 14 7 2 JOB ABCDE DUE DATE (HOURS HENCE) 36 14 16 6 26 6 10 a) Sequence the jobs according to EDD. According to the EDD rule, the sequence of jobs should be D, B, C, E, A. b) What is the average completion (flow) time? The average completion (flow) time is 19.6 days (round your response to one decimal place). c) What is the average job lateness? The average job lateness is 0.6 days (round your response to one decimal place). d) What is the average number of jobs in the system? The average number of jobs in the system is jobs (round your response to one decimal…arrow_forward

- The following jobs are waiting to be processed atJeremy LaMontagne’s machine center. Today is day 250. Using the critical ratio scheduling rule, in what sequencewould the jobs be processed?arrow_forwardRon Satterfield's excavation company uses both Gantt scheduling charts and Gantt load charts. Today, which is the end of day 7, Ron is reviewing the Gantt chart depicting these schedules: Job #151 was scheduled to begin on day 3 and to take 7 days. It got started on time and is 1 day ahead of schedule. Job #177 was scheduled to begin on day 3 and take 5 days. It is currently on time. Job #179 was scheduled to start on day 6 and take 3 days. It actually got started on day 5 and is progressing according to plan. Job #211 was scheduled to begin on day 5, but missing equipment delayed it until day 6. It is progressing as expected and should take 3 days. Job #215 was scheduled to begin on day 4 and take 5 days. It got started on time but has since fallen behind 2 days. This exercise contains only part a. a) Add the actual progress to the Gantt schedule shown on the right (on which the planned timings have been already plotted as blue lines). Using the line drawing tool, plot the actual…arrow_forwardFive customers brought in computers to be repaired to a small shop. Estimated repair times (in days) and dates promised are given below. Due dates were set based on available technicians; however, one technician had a medical emergency and will be unavailable for at least two weeks so processing times were adjusted. Customer job 1 Processing time (days) Due date (days) 6 Use the EDD rule and compute the start time, flow time, lateness, and tardiness for each job. Use minus sign to enter negative lateness values, if any. If your answer is zero, enter "0". Sequence Start Time, days Flow Time, days Lateness, days Tardiness, days -Select- -Select- -Sclect. -Select- -Select- UI 5 LI TE 10 MAarrow_forward

- Given the data below, using the SPT heuristic sequencing rule, determine the completion date and tardiness for each job as well as the average completion time and average tardiness for all four jobs. Which of the following statements is true? Job Processing time (days) Due date (in days) A 10 10 B 5 8 C 15 25 D 8 15 a.Jobs B and D will have no tardiness b.The tardiness for Job A is 12 days c.The average tardiness is 19.75 d.The average completion time is 6.5arrow_forwardA work system has five serial stations that have process times of 5, 9, 4, 9, and 8. To complete processing, a unit needs to go through all stations. What is the process cycle time of the system?arrow_forwardSo how to calculate the following below: Avg. lateness = ? days Avg. completion time = ?? days Avg. number of jobs in the system = ? jobsarrow_forward

- As the Cottrell Bicycle Co. of St. Louis completes plans for its new assembly line, it identifies 25 different tasksin the production process. VP of Operations Jonathan Cottrell now faces the job of balancing the line. He lists precedencesand provides time estimates for each step based on work-sampling techniques. His goal is to produce 1,000 bicycles perstandard 40-hour workweek.Balance this operation using the shortest operation time rule and compute the efficiency of the line.arrow_forwardA work cell in a local manufacturer has a workstation with 4 machines that form a line (Machine 1-Machine 2-Machine 3-Machine 4). Each unit needs to pass through each machine in order to be completed. Each machine has a production capacity of four units per hour. What is the process time of the work cell in minutes per unit? 15 4 8 16arrow_forward24 The job that arrived first at a work center or machine will be processed first and completed. Which of the following priority rules does this statement represent? a first come, first served b shortest processing time c critical ratio d earliest due datearrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.