Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Values are m= 360mm

n= 375mm

q= 24mm

r= 18mm

P= 0.6kN

Transcribed Image Text:01:01 Fri 3 Mar

S

T

B

오

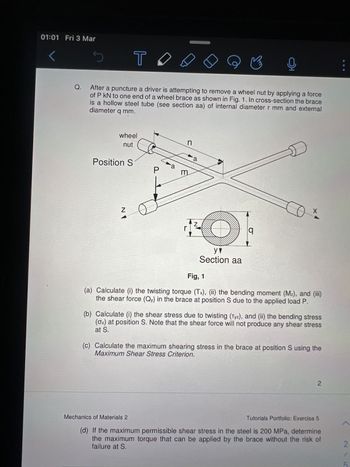

Q. After a puncture a driver is attempting to remove a wheel nut by applying a force

of P kN to one end of a wheel brace as shown in Fig. 1. In cross-section the brace

is a hollow steel tube (see section aa) of internal diameter r mm and external

diameter q mm.

wheel

nut

Position S

N

*****

a

n

m

r

a

Z

y!

Section aa

q

O

2018-

X

Fig, 1

(a) Calculate (i) the twisting torque (Tx), (ii) the bending moment (M₂), and (iii)

the shear force (Qy) in the brace at position S due to the applied load P.

(b) Calculate (i) the shear stress due to twisting (Tyz), and (ii) the bending stress

(ox) at position S. Note that the shear force will not produce any shear stress

at S.

(c) Calculate the maximum shearing stress in the brace at position S using the

Maximum Shear Stress Criterion.

2

Mechanics of Materials 2

Tutorials Portfolio: Exercise 5

(d) If the maximum permissible shear stress in the steel is 200 MPa, determine

the maximum torque that can be applied by the brace without the risk of

failure at S.

215

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 5 steps with 5 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Figure 1 shows a rotating shaft simply supported in ball bearings at A and D and loaded by a nonrotating force F of 6.8 kN. The shaft is machined from AISI 1050 cold-drawn steel. Estimate the life of the part. A 250 - 10 32 30 B 6.8 kN с D 75 100 125 10- 35 38 30 R₁₂ Figure 1. Shaft drawing showing all dimensions in millimeters; all fillets 3-mm radius A MB B M max Mc C D Figure 2. Bending-moment diagramarrow_forwardThe elongation of a bar of uniform cross section subjected to an axial force is given by the equation (omega)= PL/AE What are the dimensions of E if (omega) and L are lengths, P is a force, and A is an area?arrow_forwardX N 570mm 24° 0 AG b 320mm y 40% 530mm F 390Narrow_forward

- A 160-gram object attaches at one end of a spring and the change in length of the spring is 4 mm. What is the change in length of three springs connected in series and parallel, as shown in the figure below?arrow_forwardParvinbhaiarrow_forwardWhen a bar of 22 mm diameter is subjected to an axial pull of 60 kN the extension on the 49 mm gauge length is 0.1 mm and there is a decrease in diameter of 0.013 mm. Calculate the Young's Modulus. Provide your answer in GN/m2 to the nearest whole number.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY