Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

thumb_up100%

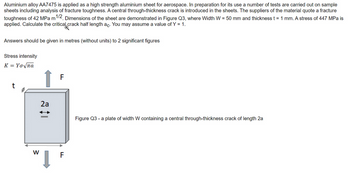

Transcribed Image Text:Aluminium alloy AA7475 is applied as a high strength aluminium sheet for aerospace. In preparation for its use a number of tests are carried out on sample

sheets including analysis of fracture toughness. A central through-thickness crack is introduced in the sheets. The suppliers of the material quote a fracture

toughness of 42 MPa m1/2. Dimensions of the sheet are demonstrated in Figure Q3, where Width W = 50 mm and thickness t = 1 mm. A stress of 447 MPa is

applied. Calculate the critical crack half length ac. You may assume a value of Y = 1.

Answers should be given in metres (without units) to 2 significant figures

Stress intensity

K = Υσ πα

t

W

2a

↓

F

F

Figure Q3- a plate of width W containing a central through-thickness crack of length 2a

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Consider a metal rod with a critical resolved shear stress of 40 MPa for a specific crystallographic plane (hkl). The angle between the normal to the plane and the applied force is 30 degrees, and the angle between the slip direction and the force is 15 degrees. Two force levels of F1 = 75 N and F2 = 40 N is applied. The cross-sectional area of the rod is 1 mm^(2). Will the slip initiate at the two force levels? Select one: a. F1: Yes, F2: No b. F1: No, F2: No OC. F1: Yes, F2: Yes Od. F1: No, F2: Yesarrow_forwardStress Strain Diagram The Data shown in the table have been obtained from a tensile test conducted on a high-strength steel. The test specimen had a diameter of 0.505 inch and a gage length of 2.00 inch. Using software. plot the Stress-Strain Diagram for this steel and determine its: A= TTdT(050s A %3D 1. Proportional Limit, 2. Modulus of Elasticity, 3. Yield Strength (SY) at 0.2% Offset, 4. Ultimate Strength (Su), 5. Percent Elongation in 2.00 inch, 6. Percent Reduction in Area, 7. Present the results (for Steps 1-6) in a highly organized table. e Altac ie sheet (as problelle 4 A = 0.2.002 BEOINNING of the effort Elongation (in) Elongation (In) Load Load #: #3 (Ib) (Ib) 1 0.0170 15 12,300 0.0004 1,500 16 12,200 0.0200 0.0010 3. 3,100 17 12,000 0.0275 0.0016 4,700 18 13,000 0.0335 5. 6,300 0.0022 19 15,000 0.0400 0.0026 6. 8,000 20 16,200 0.055 0.0032 9,500 21 17,500 0.0680 0.0035 8. 11,000 22 18,800 0.1080 0.0041 11,800 23 19,600 0.1515 0.0051 24 20,100 0.2010 10 12,300 0.0071 25…arrow_forwardA Tensile Tests of structural steel indicate that it fails whe the axial tensile strain is 1.80x10 μ. 3 Let maximum change in length that 0.25 [in] diamoren in tension car with stand before failure Length Find Structural Steel rad it It is 24 [in] in ni sa 9102arrow_forward

- Parrow_forwardA steel specimen 12mm diameter has gauge length 50mm. the steel specimen had tested via tensile test under maximum load 66KN with elongation 7.5mm, and the yield load of this specimen is 15KN with elongation 2.4mm. Calculate: 1- The engineering ultimate stress (ultimate tensile strength), and engineering strain at this point. 2- The engineering stress and strain at yield point. 3- The modulus of elasticity, and the modulus of resilience. 4- The final or fracture strain of a steel specimen, if you know that the final length of specimen after testing is 58.5mm. 5- The true stress and strain for ultimate point. any four point sirarrow_forward100 mm must elongate only 5 mm when a tensle load of 100,000 N is applied. Under these A cylindrical specimen of a brass alloy having a circumstances what must be the radius of the specimen? Consider this brass alloy to have the stress-strain behavior shown in Figure below. Tensile strengh 450 MPa (65,000 p A00 10 pu 300 200- 30 Yield strength 250 MPa (36,000 psi 2아 100 1아 100 0.005 0.20 0.30 0.40arrow_forward

- Rigid bar ABCD is loaded and supported. Steel [E=30,000 ksi] bars (1) and (2) are unstressed before the load P is applied. Bar (1) has a cross-sectional area of 0.625 in.2 and bar (2) has a cross-sectional area of 1.25 in. 2. After load P is applied, the strain in bar (2) is found to be 900 με. If there is a clearance of 0.05 in. in the pin connection at C, determine: (a) the stresses in bars (1) and (2).(b) the vertical deflection of point D.(c) the load P.arrow_forwardIn the attached picture there is a sketch of a socket wrench. Assume the wrench is held at a fixed point “A”. The yield stress of the material is known to be 500 MPa. Answer the questions below Describe the stresses at point “A” and their causes and calculate the stresses. Determine the factor of safety against yield assuming the Tresca yield criteria. Determine the factor of safety against yield assuming the von Mises yield criteria using both principal stresses and “Cartesian” stresses. Do your values match or not, and is this expected? Explain. Do the calculated values make sense with the respect to the Tresca value? Explain, why or why not?arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY