Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

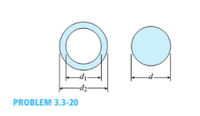

A hollow aluminum tube used in a roof structure has an outside diameter d:z=

104mm and an inside d1=82 mm (see figure). The tube is 2.75 m long, and the aluminum has shear modulus G7 = 28GPa.

a.If the tube is twisted in pure torsion by torques acting at the ends,what is the angle of twist (in degrees) when the ma.xjmum shear stress is 48 MPa?

b. what diameter disrequired for a solid shaft (see figure) to resist the same torque with the same maximum stress?

c. what is the ratio of the weight of the hollow tube to the weight of the solid shaft?

Transcribed Image Text:PROBLEM 3.3-20

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- T.L Tr4 %3D J = " (r* – rf) (Tubular shaft) Tr (Solid shaft) G.J 3. The shaft in the figure below consists of 75 mm diameter bronze segment that is rigidly joint to 50 diameter steel segment. The ends of the shaft are attached to rigid supports (fixed supports). Calculate the absolute maximum shear stress developed in each segment when the torque T= 5.1 kN-m is applied (a = 2 m and b = 1.5 m). Use G = 35 GPa for bronze, and G = 75 GPa for steel. (21 pts) 75 mm 50 mm Bronze Steelarrow_forwardI need the answer as soon as possiblearrow_forwardThe figure below shows a section of a column subjected to load P, which is applied 50 mm from the midline of the section's web. The column is made from material, which has an allowable normal stress of 180 MPa (both in tension and compression). The area of the section is 10050 mm?; the principal moments of inertia Imar = 146.554x106 mm and Imin 20.076x10° mm*. !! Determine the maximum allowable load P. 15 mm 150 mm 15 mm 150 mm 50 mm 15 mm 100 mm 100 mm 1194.6 kN 363.6 kN 1809.0 kN O 516.4 kN O 189.5 kNarrow_forward

- The shaft in Figure below consists of a 3-in. -diameter aluminum segment that is rigidly joined to a 2-in. -diameter steel segment. The ends of the shaft are attached to rigid supports, Calculate the maximum shear stress developed in each segment when the torque T= 10 kip.in is applied. Use G = 4×106 psi for aluminum and G = 12×106 psi for steel. Aluminum 3-in. diameter 6 ft T Steel 2-in. diameter 3 ftarrow_forwardA circular steel tube of length L = 1.1 m is loaded in torsion by torques T (see figure). T T r2 (a) If the inner radius of the tube is r, = 51 mm and the measured angle of twist between the ends is 0.5°, what is the shear strain y, (in radians) at the inner surface? (Enter the magnitude.) rad (b) If the maximum allowable shear strain is 0.00043 rad and the angle of twist is to be kept at 0.45° by adjusting the torque T, what is the maximum permissible outer radius (r,)may (in mm)? mmarrow_forwardA circular hollow shaft is subjected to a torsional moment T = 30 kNm and a compressiveload P = 80 kN, as shown. The shaft has an outer diameter D = 120 mmand inner diameter d = 100 mm. Points A and B are on the surface of the shaft. (a)Calculate the direct and shear stress at point A. (b)Calculate the maximum,minimum and oriention of the max and min principal stresses at point A. (c)Calculate the maximum in-plane shear stress at point A and the orientation.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY