Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

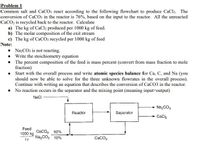

Transcribed Image Text:Problem 1

Common salt and CACO; react according to the following flowchart to produce CaCl2. The

conversion of CaCO; in the reactor is 76%, based on the input to the reactor. All the unreacted

CACO; is recycled back to the reactor. Calculate

a) The kg of CaCl2 produced per 1000 kg of feed.

b) The molar composition of the exit stream

c) The kg of CaCO; recycled per 1000 kg of feed

Note:

• Na2CO3 is not reacting.

• Write the stoichiometry equation

• The percent composition of the feed is mass percent (convert from mass fraction to mole

fraction)

• Start with the overall process and write atomic species balance for Ca, C, and Na (you

should now be able to solve for the three unknown flowrates in the overall process).

Continue with writing an equation that describes the conversion of CaCO3 in the reactor.

• No reaction occurs in the separator and the mixing point (meaning input-output)

NaCl

- Na,CO3

Reactor

Separator

-CaCl2

Feed

CaCO3 90%

NazCO3 10%

1000 kg

hr

CaCO,

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- It is desired to produce 500 kg of ethanol per hour in a continuous fermentation in a system with cell recycling. The feed culture medium contains glucose as a substrate with a concentration of 100 g/L. The kinetic expressions of growth and substrate consumption are given by: a) Knowing that X3/X1=B =3, X2=0,5X1 , that the desired conversion is 95% and that the substrate to product yield coefficient is 90% of the theoretical one, calculate the total volume of the fermenter and the recycle ratio. b) If, instead of the process with recycle, a process without recycle was used, what would be the volume of the fermenter for the same production, conversion and yield?arrow_forwardProblem 2: Liquid-liquid extraction A liquid feed stream of 1500 kg/h consisting of 35 wt. % acetonitrile (1) and 65% water (2) is to be extracted using isobutyl methyl ketone (3) as the solvent. If the flow rate of the solvent is 500 kg/h, determine the flow rates and compositions of the exit streams using the phase diagram (mass fractions) below. The overall process takes place at a constant temperature of 303 K. Acetonitrile OA 1 Extract Phase 0.2 0.8 0.4 0.6 F 0.6 E 0.4 F M 0.8 0.2 Raffinate Phase Isobutyl 1 methyl ketone 0.2 0.4 0.6 0.8 1° Water Settler,arrow_forward1. Gas absorption with a first order reaction: CO₂ is absorbed into a liquid under conditions such that the liquid side mass transfer coefficient is 2 x 10-4m/s. The diffusion coefficient of CO₂ in the liquid is 2 x 10-⁹m²/s. The interfacial concentration of CO₂ can be found using the Henry's law. Henry coefficient for CO₂ is 0.0315 bar m³/mol when expressed as p = HC at equilibrium, the C being the concentration in the liquid. The pressure is 1atm and temperature is 300K. Assume that CO₂ reacts with a dissolved solute in the liquid with a rate constant of 1s-¹. Also assume that the bulk concentration of CO₂ is zero. a. Find the Hatta number. b. Find the flux of CO₂ at the interface c. Find the flux of CO₂ going into the bulk liquid. d. What percentage of CO₂ reacts in the film itself?arrow_forward

- The formation of NO from Na and O is to be carried out in a small batch reactor. As a first approximation, we shall consider that the reaction time is more rapid than the time of cylinder compression, consequently, the reaction takes place isothermally in car eylinder at 2700 K, in a constant volume reactor (cylinder) and under a pressure of 20 atm, the initial concentration of N2 is 0.0696 mol/liter. By a specifying constant volume, we are assuming that reaction take place rapidly with respect to the movement of the piston in the cylinder. Consider that the feed consists of 77% N2, 15% Oz and 8% other gases, which may be considered inert. At this temperature the equilibrium constant (Ke-0.01). The reaction is reversible: Na + 0z + 2NO With a rate equation: Cho -TN, = k ( CN, Co, Ke Calculate: a) The equilibrium conversion of N2. b) The time required to achieve 80% of the equilibrium conversion. The formation reaction rate- constant k at this temperature is 1.11 liter mol.h' Hint: dx…arrow_forward2.133 Methanol is being produced according to the reaction CO + 2H2 CH3OH A synthesis gas stream consisting of 67.1% H2, 32.5% CO, and 0.4% CH4 (by mole) is fed into the process described below at a rate of 100 mol/h. The effluent stream from the reactor is fed into a separator (Fig. P2.13) where the methanol is completely removed, and the unconverted reactants are recycled to the reactor. To avoid the buildup of methane, a portion of the recycled stream is purged. At present operating conditions, the CO 1 2 Reactor 3 Separator 4 → Methanol 5 7 Purge Figure P2.13 Methanol rector with a separator.arrow_forwardShow all steps please, thanksarrow_forward

- An experiment on the growth rate of certain organism requires an environment of humid air enriched in oxygen. Three input streams are fed into an evaporation chamber to produce an output stream with the desired composition. A: Liquid water fed at rate of 20 cm³/min B: Air (21% O₂ and 79% N₂) C: Pure O₂ with a molar flow rate one-fifth of the molar flow rate of stream B The output gas is analyzed and is found to contain 1.5 mole% water. Draw and label the flowchart of the process, and calculate all unknown stream variables.arrow_forwardPLEASE ANSWER THIS NEED ASAParrow_forwardUsing RCRA procedures, determine if the following are classified as hazardous wastes. State the reason why or why not is is hazardous. If it is a hazardous waste, state the RCRA waste category number. Assume that the industry porducing the waste is a RCRA hazardous waste generator. 1. Sawdust in a warehouse contaminated by a spill of pentachlorobenzene. 2. Sludge from the treatment of water from the chemical conversion coating of aluminum. 3. An aqueous industrial waste stream from a plastic manufacturing plant that is discharged to a river.arrow_forward

- In the separation process illustrated below, fresh feed stream F consists of 20% A and 80% B on a mass basis. F mixes with recycle stream R to produce mixed stream M, which enters the separator. The mass ratio of A:B in stream M is 2:3. Product stream P, which leaves the separator at 100 kg/h, is pure A, while waste stream W is 5 mass % A. Recycle stream R is 80 mass % A. (a) Find all unknown stream flow rates. (b) Calculate the recycle ratio.arrow_forwardAcetic acid anhydride needs to be hydrolyzed in a continuouslyoperating cascade reactor consisting of four identical stirred tankreactors (CSTRs). The hydrolysis reaction is assumed to followfirst-order kinetics in diluted aqueous solutions.a) How large should the CSTRs be to achieve a conversion of95% at the outlet of the cascade when all the reactors operate at15°C?[10 marks]b) How large should the CSTRs be to achieve the sameconversion when all the reactors operate at 40°C?[3 marks]c) How large should be the CSTRs to achieve the sameconversion if the first reactor operates at 10°C, the second oneat 15°C, the third at 25°C, and the fourth at 40°C?[12 marks]Input volumetric flow rate of 90 L min-1is used for all cases.The rate constant has the following values at the giventemperatures: T (degrees) : 10 /15/25/40 k(min^-1) : 0.0567/0.0806/0.1580/0.3800arrow_forwardPowerplant cooling water with a temperature of 35 °C and a flowrate of 10 m3/s is discharged into a river with a temperature of 10 °C and a flowrate of 50 m3/s.a) What will the new temperature of the river be downstream of the mixing point? Draw and label your figure and state any assumptions.b) Using your knowledge of Henry’s law to justify your answer, how will this change in river temperature influence the amount of oxygen gas dissolved in the water?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The