Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

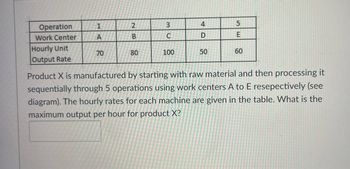

Transcribed Image Text:Operation

1

Work Center

A

2B

3

4

C

D

SE

5

Hourly Unit

70

80

100

50

60

60

Output Rate

Product X is manufactured by starting with raw material and then processing it

sequentially through 5 operations using work centers A to E resepectively (see

diagram). The hourly rates for each machine are given in the table. What is the

maximum output per hour for product X?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Similar questions

- Given this set of daily service operations, and assuming a processing order of A-B-C-D-E: Service Operation Number of Daily Reps 22 12 4 18 8 Cycle A B C D E Click here for the Excel Data File a. Determine the number of repetitions for each service if four cycles are used. Hint: include one more unit of A in Cycles 1 & 2 than in Cycles 3 & 4. Include one more unit CD in Cycles 3 & 4 than in Cycles 1 & 2. This will result in the same total number of units (repetitions) in each cycle. Cycle A B CD A B С C D E E 6 6 2 b. Determine the number of repetitions for each service if two cycles are used. 9 6 2 6 3 9 5 4 5 1arrow_forwardA production process consists of a three-step operation. The scrap rate is 13 percent for the first step and 10 percent for the other two steps. a. If the desired daily output is 472 units, how many units must be started to allow for loss due to scrap? (Do not round intermediate calculations. Round up your final answer to the next whole number.) Number of units 534 b. If the scrap rate for each step could be cut in half at every operation, how many units would this save in terms of the scrap allowance? (Do not round intermediate calculations. Round up your final answer to the next whole number.) Number of units c. If the scrap represents a cost of $10 per unit, how much is it costing the company per day for the original scrap rate (i.e. the Part a scrap rate)? (Round your final answer to the nearest whole number.) Costarrow_forwardOperation managemetnarrow_forward

- Up, Up, and Away is a producer of kites and wind socks. Relevant data on the bottleneck operation in the shop for the upcoming fiscal year are given in the following table Wind Socks 10,000 units/year Item Demand forecast Lot size Standard processing time Standard setup time Kites 32,000 units/year 25 units 0.4 hourlunit 3.0 hours/lot 70 units 0.8 hour/unit 40 hours/fol The shop works two shifts per day, 8 hours per shift, 210 days per year. Currently, the company operates four machines, and desires a 25 percent capacity cushion. How many machines should be purchased to meet the upcoming year's demand without resorting to any short-term capacity solutions? The number of additional machines required is (Enter your response rounded up to the next whole number)arrow_forwardMake legs Finish furniture Assemble Cut wood and ship Make topsarrow_forwardPlease ignore diagram in the picture. The focus is on filling out the table based on information provided in bold text. You have an upstream department that feeds two downstream packing departments: Pack Singles and Pack Multis. Those Packing departments feed a Shipping department that loads the outbound truck. 40% of your Pick volume goes to Pack Singles and has a packing rate 171 units per labor hour. 70% of the Pick volume goes to Pack multis and has a pack rate rate of 266 units per labor hour. Your pickers pick both single and multis items all day at an overall average rate of 114 units per labor hour. All units process go through the ship process at a rate of 570 units per hour. If you have 102 people and must pack 47,880 ints in pack multis over a 10 hour shift, fill out table below: Department % Volume Rate Daily volume Number of people Pick Pack single 12 Pack multus Shiparrow_forward

- . Baskin-Robbins (BR) has a line that produces half-gallon ice cream packs. All the stations inthis line are single-machine and the line is nearly balanced. Suppose that BR hired you as theproduction manager to evaluate the performance of the line. You have estimated that thebottleneck rate to be 2,337 packs per 19-hour day and the raw process time to be 30 minutes.The actual production rate of this line is 1,900 packs per day with the average cycle time of 2.9hours.(a) Estimate the average WIP for this line:WIP: ______________(b) Compare the performance of this line to the minimum expected performance:THMEP : ______________ CT MEP: ______________arrow_forwardA production process consists of a three-step operation. The scrap rate is 13 percent for the first step and 12 percent for the other two steps. a. If the desired daily output is 455 units, how many units must be started to allow for loss due to scrap? (Do not round intermediate calculations. Round up your final answer to the next whole number.) Number of units b. If the scrap rate for each step could be cut in half at every operation, how ma units would this save in terms of the scrap allowance? (Do not round intermediate calculations. Round up your final answer to the next whole number.) Number of units c. If the scrap represents a cost of $10 per unit, how much is it costing the company per day for the original scrap rate (i.e. the Part a scrap rate)? (Round your final answer to the nearest whole number.) Cost e here to search 5 6 & 7 R T Y (? 75°F Partly cloudy * 8 0 KL B N M alt ctarrow_forwardThe Big Black Bird Company (BBBC) has a large order for special plastic-lined military uniforms to be used in an urgent military operation. Working the normal two shifts of 40 hours each per week, the BBBC production process usually produces 2,500 uniforms per week at a standard cost of $120 each. 68 employees work the first shift and 30 the second. The contract price is $220 per uniform. Because of the urgent need, BBBC is authorized to use around-the-clock production six days per week. When each of the two shifts works 72 hours per week, production increases to 3,800 uniforms per week but at a cost of $144 each. a. The multifactor productivity level for two shifts working 72 hours when compared to the level of the normal two shifts.arrow_forward

- A production process consists of a three-step operation. The scrap rate is 14 percent for the first step and 8 percent for the other two steps. a. If the desired daily output is 492 units, how many units must be started to allow for loss due to scrap? (Do not round intermediate calculations. Round up your final answer to the next whole number.) b. If the scrap rate for each step could be cut in half at every operation, how many units would this save in terms of the scrap allowance? (Do not round intermediate calculations. Round up your final answer to the next whole number.) c. If the scrap represents a cost of $10 per unit, how much is it costing the company per day for the original scrap rate (i.e. the Part a scrap rate)? (Round your final answer to the nearest whole number.)arrow_forwardA process has 10 resources and two types of flow units. How many columns will therebe in the demand matrix?a. 2b. 5c. 10d. 20arrow_forwardH4. Explain properly and show all calculation stepsarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.