Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Topic Video

Question

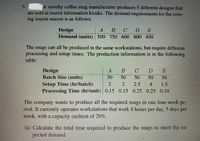

Transcribed Image Text:A novelty coffee mug manufacturer produces 5 different designs that

are sold at tourist information kiosks. The demand requirements for the com-

3.

ing tourist season is as follows:

Design

Demand (units) 500 750 600 800 450

A

B

C

DE

The mugs can all be produced in the same workstations, but require different

processing and setup times. The production information is in the following

table:

Design

Batch Size (units)

C

D

50

50

50

50

50

Setup Time (hr/batch)

Processing Time (hr/unit) 0.15 0.15 0.25 0.25 0.10

2.5

4

1.5

The company wants to produce all the required mugs in one four-week pe-

riod. It currently operates workstations that work 8 hours per day, 5 days per

week, with a capacity cushion of 20%.

(a) Calculate the total time required to produce the mugs to meet the ex-

pected demand.

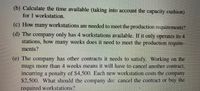

Transcribed Image Text:(b) Calculate the time available (taking into account the capacity cushion)

for 1 workstation.

(c) How many workstations are needed to meet the production requirements?

(d) The company only has 4 workstations available. If it only operates its 4

stations, how many weeks does it need to meet the production require-

ments?

(e) The company has other contracts it needs to satisfy. Working on the

mugs more than 4 weeks means it will have to cancel another contract,

incurring a penalty of $4,500. Each new workstation costs the company

$2,500. What should the company do: cancel the contract oF buy the

required workstations?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- Production Company Universal Controlsmanufactures control units. Their new models areeI Argon I and eI Argon II. To make each unit ofArgon I, use 6 meters and 3 controllers. For fa-craft each unit of Argon II, they use 10 meters and Scontrollers. The company receives a total of 760 me-managers and daily controllers of their suppliers.How many units of each model can you produce?seriously? Assume that all parts are used. Note: Solve freely # OF ARGON UNITS I # OF ARGON UNITS IIarrow_forwardComplete the MPS record below for a single item. (Enter your responses as integers. A response of "0" is equivalent to being not applicable.) Item: A Quantity on Hand: 80 Forecast Customer orders (booked) Projected on-hand inventory MPS quantity 1 70 40 ☐☐ January 2 70 65 80 Order Policy: 100 units Lead Time: 1 week February Week 4 40 0 5 45 35 50 70 45 0 8 50 0arrow_forwardExplain how is ordering in small lot sizes essential for just in time implementation and what benefi are epected to be achieved ?arrow_forward

- Problem 5: You have the following information:Demand rate = 250 units per hourLead time = 15 hourscontainer capacity = 300 units per hourSafety Stock = 20%a Determine the number of Kanban cards required.b Convert these Kanban cards into the number of hoursof demand they represent.c. If the container size is reduce from 300 to 150 units,what impacts, if any, will it have on inventory levels?arrow_forward• 1An advantage of a make-to-stock process is which of the following? o It responds directly to customer orderso It allows the firm to avoid inventory costso Rapid delivery of a standard producto All units of output are uniqueCorrect• 2According to Little’s law, which of the following can be used to estimate inventory?o Set up time times throughput rateo Process time times cycle timeo Process velocity times flow timeo Throughput rate times flow timeCorrect• 3Which of the following is a principle of reengineering? o Integrate the outcomes of parallel activitieso Organize around the taskso Treat geographically dispersed resources as though they were centralizedo Capture information many times, at the source and where it is interpretedCorrect• 4Which of the following is one of the major types of stakeholders impacted by most consulting projects?o International government regulatorso Other consultantso…arrow_forward29 Meritor is so pleased with the outcome from previous suggestions that the consultants are invited back for more work. The consultants now suggest a more complete robotic automation of the making of muffler assemblies and also a reduction in container size to five per container. Meritor implements these suggestions and the result is that the muffler assembly fabrication cell now averages approximately 20 assemblies per hour, and the catalytic converter assembly cell can now respond to an order for a batch of catalytic converters in one hour. The safety stock remains at 11.5 percent. How many kanban cards are needed? Note: Round up your answer to the next whole number.arrow_forward

- Opportunity costs are relevant to which of the following decisions? Whether to accept a special order when capacity is limited Whether to makeor buy a product No Yes No No Yes No Yes Yesarrow_forwardRick Wing has a repetitive manufacturing plant producing automobile steering wheels. Use the following data to prepare for a reduced lot size. The firm uses a work year of 300 days. Setup labor cost Annual holding cost Daily production (8 hours) Annual demand for steering wheels Desired lot size (2 hours of production) $60.00 per hour $19 per unit 1,040 units/day 33,000 (300 days x daily demand of 110 units) Q = 260 units a) Setup cost = $ b) Setup time = (round your response to two decimal places). minutes (round your response to two decimal places).arrow_forwardwhat does the ENABLE component of SCOR model cover and why is it not sequential like other parts of the model? give examplesarrow_forward

- If economic order quantity is 2,500 units and consumption in units for one year are 15,000 units, then number of orders in a year will be: a. 10 orders b. 5 orders c. 12 orders d. 6 ordersarrow_forwardRick Wing has a repetitive manufacturing plantproducing automobile steering wheels. Use the following datato prepare for a reduced lot size. The firm uses a work year of305 days. a) What is the setup cost, based on the desired lot size?b) What is the setup time, based on $40 per hour setup labor?arrow_forwardA bagel store orders cream cheese from three suppliers, Cheesy Cream Corp. (CCC), Super Smooth & Sons (SSS), and Bagel's Best Friend Co. (BBF). One month, the total order of cheese came to 100 tons. (The store does do a booming trade.) The costs were $80, $50 and $65 per ton from the three suppliers respectively, with the total cost amounting to $6,710. Given that the store ordered the same amount from CCC and BBF, how many tons of cream cheese were ordered from each supplier? Cheesy Cream Corp.____ tons Super Smooth & Sons ____tons Bagel's Best Friend Co. _____tonsarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.