Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

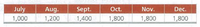

| The S&OP team at Ka nsas Furniture has received the fo llowing estimates of demand requirements: a) Assuming one-time stockout costs for lost sales of $ 100 per unit, inventory carrying costs of $25 per unit per month, and zero beginning and ending inventory, evaluate these two plans on an incremental cost basis: • Plan A: Produce at a steady rate (equal to minimum requirements) of I ,000 units per month and subcontract additional units at a $60 per unit premium cost. • Plan B: Vary the workforce, to produce the prior month's demand. The fi rm produced I ,300 units in June. The cost of hiring additional workers is $3,000 per 100 units produced. The cost of layoffs is $6,000 per l 00 units cut back. Nore: Both hiring and layoff costs are incurred in the month of the change, (i.e., going from production of I ,300 in July to 1,000 in August requires a layofT [and related costs] of 300 units in August, j ust as going from production of I ,000 in A ugust to 1,200 in September requires hiring [and rela ted costs] of200 units in September). b) Which plan is best and why? |

Transcribed Image Text:July

Aug.

Sept.

Oct.

Nov.

Dec.

1,000

1,200

1,400

1,800

1,800

1,800

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 3 images

Knowledge Booster

Similar questions

- Arrange a plan to order from the supplier using Part Period Balancing and Least Unit Cost method based on the data. Ordering lead time of the components is 1 period. Calculate the total cost of each method.arrow_forwardThe Bawl Corporation supplies alloy ball bearings to automanufacturers in Detroit. Because of its specialized manu-facturing process, considerable work-in-process and rawmaterials are needed. The current inventory levels are$2,470,000 and $1,566,000, respectively. In addition, fin-ished goods inventory is $1,200,000 and sales (at cost) forthe current year are expected to be about $48 million. Ex-press total inventory asa. Weeks of supplyb. Inventory turnsarrow_forwarda) GOT7 Soda Pop, Inc., has a new fruits drink. The production planner has assembled the following cost data and demand forecast as follow: [GOT7 Soda Pop, Inc., mempunyai minuman buah-buahan yang baru, Perancang pengeluaran telah mengumpul data tentang kos dan ramalan permintaan seperti berikut:] Quarter Demand 1,800 First Second 1,200 Third 1,600 Fourth 1,300 Table 1: Cost and demand forecast [Jadual 1: Kos dan ramalan permintaan] Previous quater's output 1,300 cases Beginning inventory 0 cases Stockout cost Inventory holding cost Hiring employees Terminating employees Subcontracting cost Unit cost on regular time Overtime cost RM150 RM40 per case at the end of quater RM40 per case RM80 per case RM60 per case RM30 per case RM15 extra per case You as the production planner need to develop an aggregate planning. You are required to: [Anda sebagai perancang pengeluaran perlu membangunkan perancangan agregat Anda dikehendaki untuk:] i) Assess plan A: strategy that hires and fires…arrow_forward

- Discuss the role of cross-functional collaboration in effective aggregate planningarrow_forwardComplete the master production schedule (enter your responses as whole numbers). On-hand inventory at end of week 1: 190 Week Forecasted demand Booked orders Projected ending inventory Master production schedule Available to promise 2 280 125 680 770 3 400 170 280 4 290 265 640 650 5 250 150 390 6 260 265 965 840 7 250 240 715 8 290 125 1295 870 555 9 310 190 985arrow_forwardQ2) Eagle Fabrication has the following aggregate demand requirements and other data for the upcoming four quarters. Quarter Demand Previous quarter's output 1500 units 1 1400 Beginning inventory 200 units 2 1000 Stockout cost $50 per unit 3 1500 Inventory holding cost $8 per unit at end of quarter 4 1300 Hiring workers $5 per unit Laying off workers $10 per unit Unit cost $30 per unit Overtime $10 extra per unit Which of the following production plans is better: Plan A—chase demand by hiring and layoffs; or Plan B—produce at a constant rate of 1200 and obtain the remainder from overtime? Finish the calculation. imagearrow_forward

- Vartan Information Technologies has a division called Useless Transistors. It is considering an « overhaul » of Useless Transistors’ operations or moving Useless overseas. Inventory management is receiving considerable attention. Vartan collected data for the years 2014, 2015, and a forecast for 2016. This data is provided below. What would be Useless Transistors’ weeks of supply for 2015? Projected 2014 2015 2016 Sales $127,890,000 $148,900,000 $192,340,000 Beginning Inventory $3,897,234 $5,467,983 $6,183,230 Ending Inventory $5,467,983 $6,183,230 $4,654,129 Cost of Goods Sold $16,876,400 $20,376,548 $22,346,786 Group of answer choicesarrow_forwardSapphire Aerospace operates 52 weeks per year, and its costof goods sold last year was $6,500,000. The firm carries eightitems in inventory: four raw materials, two work-in-processitems, and two finished goods. Table 12.3 shows last year’saverage inventory levels for these items, along with their unitvalues.a. What is the average aggregate inventory value?b. How many weeks of supply does the firm have?c. What was the inventory turnover last year?arrow_forwardThe S&OP team at Kansas Furniture, has received estimates of demand requirements as shown in the table. Assuming one-time stockout costs for lost sales of $100 per unit, inventory carrying costs of $25 per unit per month, and zero beginning and ending inventory, evaluate the following plan on an incremental cost basis: Plan A: Produce at a steady rate (equal to minimum requirements) of 1,200 units per month and subcontract additional units at a $70 per unit premium cost. Subcontracting capacity is limited to 500 units per month. (Enter all responses as whole numbers). The total cost, excluding normal time labor costs, for Plan A = $ Month Ending Subcontract Demand Production Inventory (Units) 1 July 1200 1,200 0 0 2 August 1300 1,200 0 100 3 September 1200 1,200 0 0 4 October 1700 1,200 0 500 5 November 1650 1,200 0 450 6 December 1400 1,200 0 200 (Enter your response as a whole number.)arrow_forward

- Flora’s Fabulous Fountains’ (FFF) top product is its ModelA. Using the information given, draw the product structure treefor the Model Aarrow_forwardExplain what ABC production analysis consists of.arrow_forwardQ7. The president of Rose Bowl Enterprises, Desmond Howard, projects the firms aggregate DEMAND requirements over the next 8 months as follows: These are the monthly DEMAND, not production. MONTH JAN FEB MAR APR MAY JUN JULY AUG DEMAND 1,400 1,600 1,800 1,800 2,200 2,200 1,800 1,800 PRODUCTION 1,600 from December INVENTORY 200 from Dec plus 200 His operations manager is considering a new plan, which begins in January with 200 units on hand. Stockout cost of lost sales is $100 per unit. Inventory holding cost is $20 per unit per month. Ignore any idle time costs. The plan is called plan A. Plan A: Vary the workforce level to execute a strategy that produces the quantity demanded in the prior month. The December demand was given as 1,600 units per month. Therefore, the production for JAN will be 1,600. However, only 1,400 are needed. Therefore, the extra 200 produced go into inventory and there is a holding cost for inventory. Also, per the above, you already have 200 units in inventory…arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.