Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

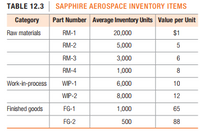

Sapphire Aerospace operates 52 weeks per year, and its cost

of goods sold last year was $6,500,000. The firm carries eight

items in inventory: four raw materials, two work-in-process

items, and two finished goods. Table 12.3 shows last year’s

average inventory levels for these items, along with their unit

values.

a. What is the average aggregate inventory value?

b. How many weeks of supply does the firm have?

c. What was the inventory turnover last year?

Transcribed Image Text:TABLE 12.3 SAPPHIRE AEROSPACE INVENTORY ITEMS

Category

Part Number Average Inventory Units Value per Unit

Raw materials

RM-1

20,000

$1

RM-2

5,000

RM-3

3,000

RM-4

1,000

8

Work-in-process

WIP-1

6,000

10

WIP-2

8,000

12

Finished goods

FG-1

1,000

65

FG-2

500

88

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 5 steps with 5 images

Knowledge Booster

Similar questions

- TOPIC : Inventory Systems for Independent Demandarrow_forwardJosie Gall's firm has developed the supply, demand, cost, and inventory data that follow. Supply Available Period 1 2 3 Regular Time 40 35 40 Overtime 15 15 15 Subcontract 10 10 10 Demand Forecast 30 units $100 $150 $200 $6 50 65 55 Initial inventory Regular-time cost per unit Overtime cost per unit Subcontract cost per unit Carrying cost per unit per month Assume that the initial inventory has no holding cost in the first period, and backorders are not permitted. Allocating production capacity to meet demand at a minimum cost using the transportation method, the total cost is (Enter your response as a whole number.)arrow_forwardGenchev Industries conducts an ABC analysis of its inventory and develops the following table from its findings. Item Annual Usage Unit Cost Dollar Usage 1 9,960 $43.20 $430,272 2 3,362 $22.80 $76,654 3 8,332 $9.90 $82,487 4 3,074 $22.30 $68,550 5 2,968 $8.40 $24,931 6 4,195 $25.00 $104,875 7 4,536 $19.20 $87,091 8 9,538 $65.60 $625,693 9 3,484 $3.20 $11,149 10 10,232 $5.70 $58,322 Which of these items is a C item? a. Item 8 b. Item 6 c. Item 5 d. Item 1arrow_forward

- Demand for stereo headphones and MP3 players for joggers has caused Nina Industries to grow almost 50 percent over the past year. The number of joggers continues to expand, so Nina expects demand for headsets to also expand, because, as yet, no safety laws have been passed to prevent joggers from wearing them. Demand for the players for last year was as follows: MONTH DEMAND (UNITS) January February 4,100 4,200 March 3,900 April 4,300 May 4,900 June 4,600 July 5,200 August 4,800 September 5,300 October 5,600 November 6,200 December 5,900arrow_forwardA major automobile manufacturer located in Georgetown, Kentucky, has two certified vendors that produce brake pads with the information shown below. New Albany Manufacturing is located in Columbus, Ohio, and LaPlaya Manufacturing is located in Monterrey, Mexico. The automobile assembly factory is assumed to operate 250 days per year. Certified Supplier New Albany Mfg. LaPlaya Mfg. Order Size (Q) 30,000 60,000 Price per Unit (P) Order quantity: Total procurement cost: Total management oversight cost: Total annual transportation cost: Annual order cost: Annual holding cost: Average annual pipeline inventory cost: Total supply chain costs: $14.38 $13.55 Oversight Cost per Unit (0) $0.00 $0.37 $ LA GA $ LA tA a. Use the Total Supply Chain Cost Excel template to compute the supply chain costs associated with each supplier if the annual demand is 480,000 brake pads. Do not round intermediate calculations. Round your answer to the nearest dollar. 30,000 units 60,000 units tA Transport Cost…arrow_forward8:02 ◄ Search Expert Q&A ☎ differentiation all can reduce the amount of inventory in the supply chain? Which of the following best explains why location pooling, lead-time pooling, and delayed Done All three strategies reduce the in-stock probability. O All three strategies make customers wait longer to receive their product. O All three strategies reduce the total lead time from the supply source (e.g., a factory) to the end consumer. All three strategies reduce the variability demand within the supply chain.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.