Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

Transcribed Image Text:ing Design

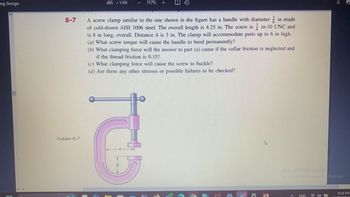

8-7

Problem 8-7

485 / 1109

157%

A screw clamp similar to the one shown in the figure has a handle with diameter

in made

of cold-drawn AISI 1006 steel. The overall length is 4.25 in. The screw is in-10 UNC and

is 8 in long, overall. Distance A is 3 in. The clamp will accommodate parts up to 6 in high.

(a) What screw torque will cause the handle to bend permanently?

(b) What clamping force will the answer to part (a) cause if the collar friction is neglected and

if the thread friction is 0.15?

(c) What clamping force will cause the screw to buckle?

(d) Are there any other stresses or possible failures to be checked?

ट

Activate Windows

Go to Settings to activat Windows.

ENG

8:58 PM

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Similar questions

- I need answer in 10 minutes please quicklyarrow_forwardA screw clamp shown in the figure has a handle with diameter 5 mm made of cold-drawn AISI 1006 steel (table E18 - page 1195). The overall length of the hand is 75 mm. The screw is M 12 coarse (table 8-1) and is 145 mm long, overall. Distance A is 50 mm. The clamp will accommodate parts up to 105 mm high.a) What is the value of screw torque that causes the handle to bend permanently?b) If the collar friction is neglected and if the thread friction is 0.075, what is the screw force value that causes the handle to bend permanently?c) What is the value of clamping force, which will cause the screw to buckle?d) Are there any other stresses or possible failures to be checked?e) If yes, calculate them.arrow_forward2. A screw clamp shown in the figure has a horizontal handle with diameter 3/8-in made of cold-drawn AISI 1006 steel. The overall length of the handle is 4.25 in. The screw is single-threaded, 3/4 in-10 UNC, and is 8 in long, overall. a. What screw torque will cause the horizontal handle to bend permanently? b. What clamping force will the answer to part a) cause if the collar friction is neglected and if the thread friction is 0.15? Hint: 1) Assume a force Fis applied at the end of the handle. Think about how this force affects the screw vs. how it affects the handle. 2) Consider in which direction the screw is "raised". - 4.25 inarrow_forward

- Don't do copy paste from other platforms.arrow_forward10) A screw clamp similar to the one shown in the figure has a handle with diameter in made of cold-drawn AISI 1006 steel. The overall length is 3 in. The screw is in-14 UNC and is 5 in long. overall. Distance A is 2 in The clamp will accommodate parts up to 4 in tagh. (a) What screw torque will cause the handle to bend permanenly? See sample problem 10.1, sections 10.4, 10.7 Given; hordle dia : 16 in L: 3in. Disa: Zin 10/29 Find: Scrcw torque ,! Assumphon : The screw torque is far cold decun AISI 1006 steel. a L: 3- 8 2.406 in %3D 4 32 T: 2.406F H:(L-3) -굵)F. 2.188F F- (2406 F: 2.188F Sy: 41 Kpsi. 32 (2-188) F TI (O.1875)3 Sy = 32M F-12:13 1bf T. 2.406 CI2:13) = 29.216f. in The lorque of the screw which will couse the scoch to bend pemorently is 29.21of. in. is 29.210f.10.arrow_forwardThe figure below shows a boat propeller mounted on a drive shaft with a 7 mm diameter (d) cylindrical drive pin inserted through the hub and the shaft. The drive shaft diameter, D, inside the hub is 69 mm. The pin is made from AISI 1020 cold rolled steel, which has a yield stress of 427 MPa and an ultimate stress of 621 MPa. If the drive pin is subjected to an overload (e.g. strikes a log), calculate the torque (Nm) required to shear the pin. Note: Assume that the max shear stress of the pin material is approximately equal 82% of the ultimate tensile stress. Do not include units in your answer. Pin F Hub Drive pin Shaft Drive shaft F Shear planes Hub Answer:arrow_forward

- The C-clamp in Figure P10–9 is made of cast zinc, ZA12. Determine the allowable clamping force that the clamp can exert if it is desired to have a design factor of 4 based on ultimate strength in either tension or compression.arrow_forwardplease help solve and explain and include FBD pleasearrow_forwardMaterial is AISI 1060. Please do not upload wrong solution from different materials. The value tried was incorrect, need help thank you.arrow_forward

- Provide FBD and solution.arrow_forwardThe two lever assembly shown below is subject to a static load F = 8250 lb. %3D (a) identical links BD can be made from based on the stress in the middle of each link. Specify the lowest-strength alloy steel from Appendix A-10 that the two (b) is the minimum recommended diameter that the pins can be machined to? The pins at B and D are made from SAE 4140 OQT 900 alloy steel. What What is the bearing stress on the pins at B and D based on the pin (c) diameter you calculated in part (b) above? 9 in 8 in C B Top View A В C B 0.75 in - -0.31 in F 0.31 in Side View Front Viewarrow_forwardSolve the question in the image uploaded.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY