Managerial Accounting: The Cornerstone of Business Decision-Making

7th Edition

ISBN: 9781337115773

Author: Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

I need typing clear urjent no chatgpt use i will give 5 upvotes

full explanation

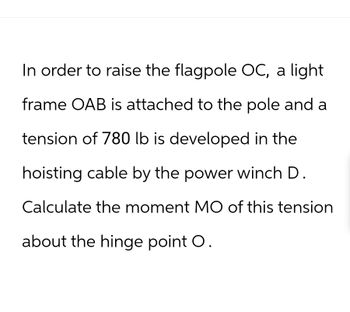

Transcribed Image Text:In order to raise the flagpole OC, a light

frame OAB is attached to the pole and a

tension of 780 lb is developed in the

hoisting cable by the power winch D.

Calculate the moment MO of this tension

about the hinge point O.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- One kg of water within a piston-cylinder assembly executes a Carnot power cycle. During isothermal expansion, the water is heated from a saturated liquid at 50 bar until is a saturated vapor. The vapor then expands adiabatically to a pressure of 5 bar and a quality of 0.8291. a) Sketch the cycle on P-v and T-s diagram. b) Evaluate the heat transfer and wor for the above processes (isothermal expansion and adiabatic expansion) c) Evaluate the thermal efficiency.arrow_forwardVernon Inc. has analyzed the setup time on its computer-controlled lathe. The setup requireschanging the type of fixture that holds a part. The average setup time has been 140 minutes,consisting of the following steps: Turn off machine and remove fixture from lathe 15 minutesGo to tool room with fixture 15Record replacement of fixture to tool room 18Return to lathe 20Clean lathe 20Return to tool room 20Record withdrawal of new fixture from tool room 12Return to lathe 15Install new fixture and turn on machine 5Total setup time 140 minutesa. Why should management be concerned about improving setup time?b. What do you recommend to Vernon Inc. for improving setup time?c. How much time would be required for a setup, using your suggestion in (b)?arrow_forwardThe production department is proposing the purchase of an automatic insertion machine. It has identified three machines and has asked the accountant to analyze them to determine which one has the best average rate of return. Machine A $43,529.50 $80,697.00 Machine B Machine C $64,675.95 310,925.00 268,990.00 431,173.00 Estimated average income Average investment Oa. Machine B Ob. Machine A Oc. Machine C Od. Machines B and C have the same preferred average rate of return.arrow_forward

- A manager must decide between two machines. The manager will take into account each machine's operating costs and initial costs, and its breakdown and repair times. Machine A has a projected average operating time of 131 hours and a projected average repair time of 4 hours. Projected times for machine B are an average operating time of 61 hours and a repair time of 5 hours. What are the projected availabilities of each machine? (Round your answers to 3 decimal places.) Answer is complete but not entirely correct. Availability 0.952 0.945 Machine A Machine Barrow_forwardUse the following infonnation for Exercises 5-44 through 5-46: The following sixsituations at Diviney Manufacturing Inc. are independent. A manual insertion process takes 30 minutes and 8 pounds of material to produce a Automating the insertion process requires 15 minutes of machine time and 7.5 pounds of material. The cost per labor hour is $12, the cost per machine hour is $ 8, and the cost per pound of materials is $10. With its original design, a gear requires 8 hours of setup By redesigning the gear so that the number of different grooves needed is reduced by 50%, the setup time is reduced by 75%.The cost per setup hour is $50. A product currently requires 6 By redesigning the manufacturing layout, the number of moves can be reduced from 6 to o. The cost per move is $20. Inspection time for a plant is 16,000 hours per The cost of inspection consists of salaries of 8 inspectors, totaling $320,000. Inspection also uses supplies costing $5 per inspection hour. The company…arrow_forwardtyping plsarrow_forward

- Medinc produces disinfectants by mixing 2 chemical solutions in a machine to become a disinfectant solution (solution 1 and solution 2). Solution 1 is the first process which is carried out at workstation A for 0.5 minutes per solution then continued at workstation B for 0.2 minutes per solution. Then together solution 1 is mixed with solution 2 at workstation C for 0.8 minutes per solution. Workstations B and C are processed at workstation D for mixing together where the process is 10 minutes per solution until it becomes a disinfectant solution for sale to customers. a. Which workstations are the bottleneck? Explain with a picture of the workstation.b. What is the resulting time (throughput time) of the entire work system above?c. How much disinfectant solution can a company produce per hour?arrow_forwardUse the following information for Exercises 5-44 through 5-46: The following six situations at Diviney Manufacturing Inc. are independent. a. A manual insertion process takes 30 minutes and 8 pounds of material to produce a product. Automating the insertion process requires 15 minutes of machine time and 7.5 pounds of material. The cost per labor hour is 12, the cost per machine hour is 8, and the cost per pound of materials is 10. b. With its original design, a gear requires 8 hours of setup time. By redesigning the gear so that the number of different grooves needed is reduced by 50%, the setup time is reduced by 75%. The cost per setup hour is 50. c. A product currently requires 6 moves. By redesigning the manufacturing layout, the number of moves can be reduced from 6 to 0. The cost per move is 20. d. Inspection time for a plant is 16,000 hours per year. The cost of inspection consists of salaries of 8 inspectors, totaling 320,000. Inspection also uses supplies costing 5 per inspection hour. The company eliminated most defective components by eliminating low-quality suppliers. The number of production errors was reduced dramatically by installing a system of statistical process control. Further quality improvements were realized by redesigning the products, making them easier to manufacture. The net effect was to achieve a close to zero-defect state and eliminate the need for any inspection activity. e. Each unit of a product requires 6 components. The average number of components is 6.5 due to component failure, requiring rework and extra components. Developing relations with the right suppliers and increasing the quality of the purchased component can reduce the average number of components to 6 components per unit. The cost per component is 500. f. A plant produces 100 different electronic products. Each product requires an average of 8 components that are purchased externally. The components are different for each part. By redesigning the products, it is possible to produce the 100 products so that they all have 4 components in common. This will reduce the demand for purchasing, receiving, and paying bills. Estimated savings from the reduced demand are 900,000 per year. 5-44 Nonvalue-Added Costs Refer to the information for Diviney Manufacturing on the previous page. Required: Estimate the nonvalue-added cost for each situation.arrow_forwardJay Corporation has provided data from a two-year period to aid in planning. The Controller has asked you to prepare a contribution format income statement. Use the information included in the Excel Simulation and the Excel functions described below to complete the task. • Cell Reference: Allows you to refer to data from another cell in the worksheet. From the Excel Simulation below, if in a blank cell, "=84" was entered, the formula would output the result from cell B4. or 17.000 in this example. • Basle Math funetlons: Allows you to use the basic math symbols to perform mathematical functions. You can use the following keys: (plus sign to add). - (minus sign to subtract). * (asterisk sign to multiply), and / (forward slash to divide). From the Excel Simulation below, if in a blank cell "=B19+B20" was entered, the formula would add the values from those cells and output the result, or 183,.800 in this example. If using the other math symbols the result would output an appropriate…arrow_forward

- Use the following information for Exercises 5-44 through 5-46: The following six situations at Diviney Manufacturing Inc. are independent. a. A manual insertion process takes 30 minutes and 8 pounds of material to produce a product. Automating the insertion process requires 15 minutes of machine time and 7.5 pounds of material. The cost per labor hour is 12, the cost per machine hour is 8, and the cost per pound of materials is 10. b. With its original design, a gear requires 8 hours of setup time. By redesigning the gear so that the number of different grooves needed is reduced by 50%, the setup time is reduced by 75%. The cost per setup hour is 50. c. A product currently requires 6 moves. By redesigning the manufacturing layout, the number of moves can be reduced from 6 to 0. The cost per move is 20. d. Inspection time for a plant is 16,000 hours per year. The cost of inspection consists of salaries of 8 inspectors, totaling 320,000. Inspection also uses supplies costing 5 per inspection hour. The company eliminated most defective components by eliminating low-quality suppliers. The number of production errors was reduced dramatically by installing a system of statistical process control. Further quality improvements were realized by redesigning the products, making them easier to manufacture. The net effect was to achieve a close to zero-defect state and eliminate the need for any inspection activity. e. Each unit of a product requires 6 components. The average number of components is 6.5 due to component failure, requiring rework and extra components. Developing relations with the right suppliers and increasing the quality of the purchased component can reduce the average number of components to 6 components per unit. The cost per component is 500. f. A plant produces 100 different electronic products. Each product requires an average of 8 components that are purchased externally. The components are different for each part. By redesigning the products, it is possible to produce the 100 products so that they all have 4 components in common. This will reduce the demand for purchasing, receiving, and paying bills. Estimated savings from the reduced demand are 900,000 per year. 5-45 Driver Analysis Refer to the information for Diviney Manufacturing on the previous page. Required: CONCEPTUAL CONNECTION For each situation, identify the possible root cause(s) of the activity cost (such as plant layout, process design, and product design).arrow_forwardKlassen Toy Company, Inc., assembles two parts (parts 1 and 2): Part 1 is first processed at workstation A for 10 minutes per unit and then processed at workstation B for 15 minutes per unit. Part 2 is simultaneously processed at workstation C for 12 minutes per unit. Work stations B and C feed the parts to an assembler at workstation D, where the two parts are assembled. The time at workstation D is 20 minutes. a) The bottleneck of this process is workstation D at 20 minutes per unit (enter your response as a whole number). b) The hourly capacity of the process is units (enter your response as a whole number).arrow_forwardMCE Craig, Inc., has provided the following information for one of its products for each hour of production: Actual velocity: 200 units (per hour) Move time: 11 minutes Inspection time: 12 minutes Rework time: 12 minutes 1. MCE is 0.42 2. What is the theoretical cycle time? Calculate MCE using actual and theoretical cycle times. If required, round your answers to two decimal places. Theoretical cycle time fill in the blank minutes Actual cycle time 0.3 minutes MCE fill in the blankarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning,

Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning, Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...

Accounting

ISBN:9781337115773

Author:Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:Cengage Learning

Principles of Accounting Volume 2

Accounting

ISBN:9781947172609

Author:OpenStax

Publisher:OpenStax College

Cornerstones of Cost Management (Cornerstones Ser...

Accounting

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Cengage Learning

Managerial Accounting

Accounting

ISBN:9781337912020

Author:Carl Warren, Ph.d. Cma William B. Tayler

Publisher:South-Western College Pub

Financial And Managerial Accounting

Accounting

ISBN:9781337902663

Author:WARREN, Carl S.

Publisher:Cengage Learning,

Essentials of Business Analytics (MindTap Course ...

Statistics

ISBN:9781305627734

Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. Anderson

Publisher:Cengage Learning