Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

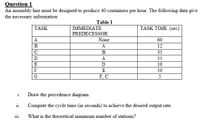

Transcribed Image Text:Question 1

An assembly line must be designed to produce 40 containers per hour. The following data give

the necessary information

Table 1

TASK

IMMEDIATE

TASK TIME (sec)

PREDECESSOR

A

None

60

B

A

12

B

35

D

A

55

E

10

F

E

50

G

F, C

i.

Draw the precedence diagram.

11.

Compute the cycle time (in seconds) to achieve the desired output rate.

111.

What is the theoretical minimum number of stations?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 3 images

Knowledge Booster

Similar questions

- Order 1 2 3 4 5 Time Since Order Arrived (hours ago) 3 1 0 6 5 You answered Sequence Order The due dates reflect the need for the order to be at its next operation. Develop separate schedules by using the FCFS and EDD rules. Compare the schedules on the basis of average flow time and average past due hours. Using the FCFS (first come, first served) decision rule for sequencing the orders, the order is Sequence Order Estimated Machine Time (hours) 15 9 7 10 3 1 5 Rule EDO FCFS 4 4 Using the EDD (earliest due date) decision rule for sequencing the orders, the order is (to resolve a tie, use order in which the orders were received) ¹2 1 4 2 3 Due Date (hours from now) 5 5 3 18 20 21 12 The average flow time and average past due hours for each option (enter your responses are real numbers rounded to two decimal place Average Flow Time Average Past Due Hoursarrow_forwardProblem 14-7 (Algo) Compute the takt time for a system where the total time per shift is 390 minutes, there is one shift, and workers are given 2 13-minute breaks and 25 minutes for lunch. Daily demand is 344 units. (Round your answer to 2 decimal places.) Takt time minutes per cyclearrow_forward2-The process of making hotdogs involves six activities: “grind”, “mix”, “stuff”, “cook”, “peel”, and “inspect”. If the capacity of activity “cook” determines the process capacity, which of the following statements are true? a- Activity “cook” is a bottleneck activity. b- The activity time of all the other five activities is shorter than activity "cook". c- Cycle time of the process of making hotdogs is equal=1/capacity of activity “cook”. d- Increasing the capacity of activity “grind” can increase the capacity of the process of making hotdogs. All statements are correct Only statement 'b' is correct Only statements 'a' and 'b' are correct Only statements 'a', 'b' and 'c' are correct Only statement 'a' is correct Only statement 'd' is correctarrow_forward

- h ow do production plants handle maintenance and repair activities to minimize downtime?arrow_forwardI have uploaded 2 pictures of the question.arrow_forwardIn the three-station process depicted in the figure below a product must go through one of the two machines at station 1 (they are parallel) before proceeding to station 2. (hr-hour, min-minutes) Capacity: 4 units/hr Station 1 Machine A Station 2 Station 3 Station 1 Machine B Capacity: Capacity: 12 units/hr 5 units/hr Capacity: 4 units/hr In one hour at most how many products the process can produce? O 5 units/hr 8 units/hr 12 units/hr O None of the abovearrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.