Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

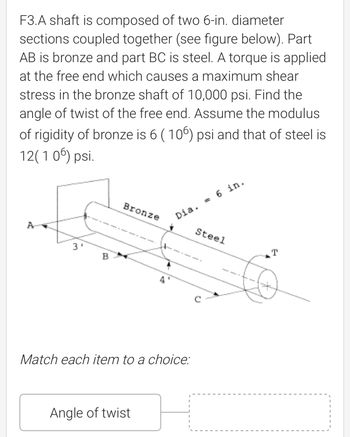

Transcribed Image Text:F3.A shaft is composed of two 6-in. diameter

sections coupled together (see figure below). Part

AB is bronze and part BC is steel. A torque is applied

at the free end which causes a maximum shear

stress in the bronze shaft of 10,000 psi. Find the

angle of twist of the free end. Assume the modulus

of rigidity of bronze is 6 (106) psi and that of steel is

12(106) psi.

Bronze

Dia. = 6 in.

A

3'

Steel

B

Match each item to a choice:

Angle of twist

T

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A shaft used in an aircraft engine is 50 mm diameter, the maximum allowable shear stress is 84 MN/m². Find the torsional strength of the shaft. If the shaft now has a hole bored in it, find the percentage reductions in strength and mass. a. If the hole is 40 mm diameter b. If the hole is 25 mm diameter.arrow_forwardThe composite shaft shown in the figure consists of two steel pipes that are connected at flange B and securely attached to rigid walls at A and C. Steel pipe (1) has an outside diameter of 168 mm and a wall thickness of 5 mm. Steel pipe (2) has an outside diameter of 126 mm and a wall thickness of 8 mm. Both pipes are 2.4 m long and have a shear modulus of 79 GPa. If a concentrated torque of 22 kN-m is applied to flange B, determine (a) the maximum shear stress magnitudes in pipes (1) and (2). (b) the rotation angle of flange B relative to support A. N Swors: LI (1) TB. B L2 (2) C Xarrow_forward2. A shaft is designed to carry torque as shown below. The shaft consists of a steel rod which is fixed against rotation at both ends. In addition, the left half of the rod is well bonded to an aluminum sleeve. The assembly is loaded by a torque of 2000 N-m as shown. - The steel rod has shear modulus G = 80 GPa and radius r= 1.5 cm (hence polar moment of inertia Ip = 7.95 x 108 m². The aluminum sleeve has shear modulus G = 26 GPa, outer radius 2.6 cm and inner radius 1.5 cm (hence polar moment of inertia I, = 7.95 x 108 m²). 2000 N sleeve -0.57 rod a. Calculate the total reaction torques at the two walls (points A and C). b. Calculate the maximum shear stresses in the steel rod and the aluminum sleeve. c. Calculate the angle of twist at point B.arrow_forward

- 1. A solid steel shaft ABCDE having diameter d = 40 mm turns with a constant angular velocity and freely in bearings at points A and E. The shaft is driven by a gear at C, which applies a torque T₂ = 625 N_m in the direction shown in the figure. Gears at B and D are driven by the shaft and have resisting torques T₁ and T3, acting in the opposite direction to the torque T2. We know T₁ = 400 N.m, but T3 is not explicitly given in the problem. Segments BC and CD have lengths LBC= 550 mm and LCD = 400 mm, respectively, and the shear modulus G = 80 GPa. Determine the maximum shear stress in each segment of the shaft and the angle of twist between gears B and D. pôrôć -LBC LCD T3 Earrow_forwardA steel stepped shaft ABCD fixed at A is subjected to three torques at points B, C and D, with magnitudes T₁ = 40 kip-in, T₂ = 50 kip-in and Ts= 30 kip-in and directions as shown in Figure 1.1. The segments AB and BC are solid with diameters dx = 3 in and dec = 2 in respectively, while segment CD is hollow with an outer diameter dan 1.5 in and a wall thickness of 0.25 in. The shear modulus of elasticity is equal to G=11.6x10³ ksl. T₁ T₂ 4 = 20 in A B L₂ = 20 in Figure 1.1 a) Draw the torsion moment diagram for the shaft and calculate how long should segment CD be so that the angle of twist between points B and D is equal to zero. T₁ 4₂-25 in b) If Ts is dropped, a fixed support is added at point D (as shown in Figure 1.2) and the length of segment CD is equal to 15 in, find the support reactions at points A and D and the maximum shear stress developed in segment BC. The magnitudes of the torques at points B and Care the same as in part a). B C L₂= 25 in T₂ * Figure 1.2 Hollow C Hollow…arrow_forwardTorsional T is applied to the hollow axis (G=80 GPa). Ewha Womans University, the maximum shear strain is γmax = 640 × 10-6rad Igo, inside andThe outside diameters are 120mm and 150mm, respectively.a. What is the maximum axial strain?b. Maximum axial stress?c. What is the maximum torque (T) meeting the above conditions?arrow_forward

- A torsional bar is subjected to two external torques (10NM and 5Nm) and a distributed torque (15NM/m) at the locations indicated in the picture. The angle of twist at A (z = 0) is 0. The shcar modulus is 2GP.. Compute the following quantitics: (a) the reaction moment at A, (b) the angle of twist at B, and (c) the angle of twist at C. OD=5cm OD=4cm 15Nm/m 10Nm 5 Nm A 15 cm 10cm 8 cm 15 cm F A 8cm B Carrow_forwardPlease help. This problem involves torsional stress and strain. Thank you.arrow_forwardA shaft ABCD is supported by a clamp at point A and is subjected to point torques at B, C and D, as shown in the figure. The shaft has variable cross-section and is solid in segments AB and CD and hollow in segment BC. The lengths and diameters of each segment are shown in the figure. Assume that the deformation is linear elastic and take the shear modulus of elasticity G = 12.1 × 10° psi. a) Using method of sections, plot the torsion moment diagram. b) Find the angle of twist for the free end (point D) with respect to the fixed support at A, QAD and the angle of twist for point C with respect to the fixed support at A, QCA. Find both angles in degrees. d₁ = 4 in d20 3.5 in, d2=2.5 in d3 = 3.0 in 25 kip-in 20 kip-in 10 kip-in A 20 in B с D ++ 25 in 30 inarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY