FINANCIAL ACCOUNTING

10th Edition

ISBN: 9781259964947

Author: Libby

Publisher: MCG

expand_more

expand_more

format_list_bulleted

Question

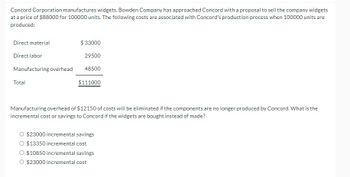

Transcribed Image Text:## Concord Corporation: Incremental Cost Analysis

### Production Costs for 100,000 Units

Concord Corporation manufactures widgets, and Bowden Company has proposed a deal to sell Concord the widgets at a price of $88,000 for 100,000 units. Below are the costs associated with Concord's production process for producing 100,000 units:

- **Direct Material:** $33,000

- **Direct Labor:** $29,500

- **Manufacturing Overhead:** $48,500

**Total Cost:** $111,000

### Incremental Cost/Savings Analysis

If Concord buys the widgets instead of making them, a manufacturing overhead cost of $12,150 will be eliminated. We need to determine the incremental cost or savings for Concord when deciding to buy the widgets from Bowden Company instead of producing them internally.

### Calculation Options

Choose the correct incremental cost or savings from the options below:

- \( \boxed{\$23,000 \text{ incremental savings}} \)

- \( \boxed{\$13,350 \text{ incremental cost}} \)

- \( \boxed{\$10,850 \text{ incremental savings}} \)

- \( \boxed{\$23,000 \text{ incremental cost}} \)

### Steps to Determine Incremental Cost/Savings

To solve for the incremental cost or savings, follow these steps:

1. **Calculate the reduced manufacturing overhead if components are no longer produced:**

$$ \text{Reduced Manufacturing Overhead} = \$48,500 - \$12,150 = \$36,350 $$

2. **Calculate the total savings from not producing the widgets:**

$$ \text{Total Cost of Production} = \$111,000 $$

$$ \text{Cost without Overhead Savings} = \$111,000 - \$12,150 = \$98,850 $$

3. **Compare the cost of buying versus making:**

Compare the cost of buying the widgets (\$88,000) with the cost of making them without the overhead savings (\$98,850).

4. **Determine the Incremental Savings:**

$$ \text{Incremental Savings} = \$98,850 - \$88,000 = \$10,850 $$

Therefore, the incremental savings for Concord if the widgets are bought instead of made is \( \$10,850 \).

### Conclusion

The correct option is:

\[ \boxed{\$10,850 \text

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Similar questions

- Vista Company manufactures electronic equipment. It currently purchases the special switches used in each of its products from an outside supplier. The supplier charges Vista $1.80 per switch. Vista’s CEO is considering purchasing either machine A or machine B so the company can manufacture its own switches. The projected data are as follows: Machine A Machine B Annual fixed costs $ 141,450 $ 188,325 Variable cost per switch 0.57 0.25 Required: For each machine, what is the minimum number of switches that Vista must make annually for total costs to equal outside purchase cost? What volume level would produce the same total costs regardless of the machine purchased? What is the most profitable alternative for producing 155,000 switches per year and what is the total cost of that alternativearrow_forwardCan you please check my workarrow_forwardFutura Company purchases the 66,000 starters that it installs in its standard line of farm tractors from a supplier for the price of $12.10 per unit. Due to a reduction in output, the company now has idle capacity that could be used to produce the starters rather than buying them from an outside supplier. However, the company's chief engineer is opposed to making the starters because the production cost per unit is $13.10 as shown below: Direct materials. Direct labor Supervision Depreciation Variable manufacturing overhead Rent Total product cost Per Unit $ 7.00 2.20 1.80 1.20 0.40 0.50 $ 13.10 Total $ 118,800 $ 79,200 $ 33,000 If Futura decides to make the starters, a supervisor would have to be hired (at a salary of $118,800) to oversee production. However, the company has sufficient idle tools and machinery such that no new equipment would have to be purchased. The rent charge above is based on space utilized in the plant and can't be avoided. The total rent on the plant is $81,000…arrow_forward

- Wings Incorporated manufactures machine parts for aircraft engines. The CEO, Chucky Valters, was considering an offer from a subcontractor that would provide 2,400 units of product PQ107 for Valters for a price of $150,000. If Wings does not purchase these parts from the subcontractor it must produce them in-house with the following unit costs: Direct materials Direct labor Variable overhead Cost per Unit $31 19 8 In addition to the above costs, if Wings produces part PQ107, it would have a retooling and design cost of $9,800. The relevant costs of producing 2,400 units of product PQ107 internally are:arrow_forwardConcord Music produces 59600 blank CDs on which to record music. The CDs have the following costs: Direct Materials $10000 Direct Labour 15700 Variable Overhead 3300 Fixed Overhead 6600 None of Concord’s fixed overhead costs can be reduced, but another product could be made that would increase the operating income by $4500 if the CDs were acquired externally. If cost minimization is the major consideration and the company would prefer to buy the CDs, what is the maximum external price that Concord would be willing to accept to acquire the 59600 units externally? $31100 $40100 $35600 $33500arrow_forwardUramilabenarrow_forward

- Millennium Printers Inc. manufactures color laser printers. Model L-1819 presently sells for $150 and has a total product cost of $120, as follows: Direct materials $90 Direct labor 20 Factory overhead 10 Total $120 It is estimated that the competitive selling price for color laser printers of this type will drop to $140 next year. Millennium Printers wants to establish a target cost to maintain its historical markup percentage on product cost. Engineers have provided the following cost reduction ideas: Purchase a plastic printer cover with snap-on assembly. This will reduce the amount of direct labor by nine minutes per unit. Add an inspection step that will add six minutes per unit of direct labor but reduce the materials cost by $3 per unit. Decrease the cycle time of the injection molding machine from four minutes to three minutes per part. Thirty percent of the direct labor and 45% of the factory overhead is related to running injection molding machines. The direct…arrow_forwardCan I get some help on this problem, please?arrow_forwardNelly Technology manufactures a particular computer component. Currently, the costs per unit are asfollows:Direct material P 50Direct labor 500Variable overhead 250Fixed overhead 400Fur Inc. has obtained Nelly with a offer to sell 10,000 units of the component for P1,100 per unit. IfNelly accepts the proposal, P2,500,000 of the fixed overhead will be eliminated. Should Nelly makeor buy the component?arrow_forward

- A distributor of fasteners is opening a new plant and considering whether to use a mechanized process or a manual process to package the product. The manual process will have a fixed cost of $36,234 and a variable cost of $2.14 per bag. The mechanized process would have a fixed cost of $84,420 and a variable cost of $1.85 per bag. The company expects to sell each bag of fasteners for $2.75. a) What is the break-even point for the manual process (in units)? b) What is the break-even point for the mechanized process (in units)? c) A point of indifference for two processes is quantity at which each process generates the same amount of profit (review video). What is the point of indifference for the two processes? (Hint: 1) Use equations to set profit of manual process equal to mechanized process and solve for quantity; 2) (Excel) If you have a break-even for each process - have only one cell that represents quantity that be used to calculates costs/revenues for each process and use Goal…arrow_forwardWhat are the fixed overhead costs of making the component?arrow_forwardBramble Corp. incurs the following costs to produce 12000 units of a subcomponent: Direct materials $8400 Direct labor 12000 Variable overhead 12000 Fixed overhead 19000 An outside supplier has offered to sell Bramble the subcomponent for $2.15 a unit. No fixed costs are avoidable. If Bramble accepts the offer, it could use the production capacity to produce another product that would generate additional income of $3600. The increase (decrease) in net income from accepting the offer would be O $(3600). $10200. O $(3000). O $3000.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning,

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning, Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning,

Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning, Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON

Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education

Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Accounting

Accounting

ISBN:9781337272094

Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.

Publisher:Cengage Learning,

Accounting Information Systems

Accounting

ISBN:9781337619202

Author:Hall, James A.

Publisher:Cengage Learning,

Horngren's Cost Accounting: A Managerial Emphasis...

Accounting

ISBN:9780134475585

Author:Srikant M. Datar, Madhav V. Rajan

Publisher:PEARSON

Intermediate Accounting

Accounting

ISBN:9781259722660

Author:J. David Spiceland, Mark W. Nelson, Wayne M Thomas

Publisher:McGraw-Hill Education

Financial and Managerial Accounting

Accounting

ISBN:9781259726705

Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting Principles

Publisher:McGraw-Hill Education