FINANCIAL ACCOUNTING

10th Edition

ISBN: 9781259964947

Author: Libby

Publisher: MCG

expand_more

expand_more

format_list_bulleted

Question

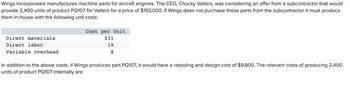

Transcribed Image Text:Wings Incorporated manufactures machine parts for aircraft engines. The CEO, Chucky Valters, was considering an offer from a subcontractor that would

provide 2,400 units of product PQ107 for Valters for a price of $150,000. If Wings does not purchase these parts from the subcontractor it must produce

them in-house with the following unit costs:

Direct materials

Direct labor

Variable overhead

Cost per Unit

$31

19

8

In addition to the above costs, if Wings produces part PQ107, it would have a retooling and design cost of $9,800. The relevant costs of producing 2,400

units of product PQ107 internally are:

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Similar questions

- Leach Finishing makes various metal fittings for the construction industry. Three of the fittings, models X-12, X-24, and X-30, require grinding on a patented machine of which Leach has only one. The cost of production information for the three products follow: X-12 $35 $ 20 18.0 Price per fitting Variable cost per fitting Units per hour of grinding The testing machine used for both models has a capacity of 3,230 hours annually. Fixed manufacturing costs are $496,000 annually. Required A Required B X-24 $ 51 $ 27 12.5 Required: a. Suppose that Leach Finishing can sell at most 59,200 units of any one fitting. How many units of each fitting model should Leach Finishing produce annually? b. Suppose that Leach Finishing can sell at most 18,000 units of any one fitting. How many units of each fitting should Leach Finishing produce annually? X-30 $ 70 $ 44 10.0 Complete this question by entering your answers in the tabs below. X-12 X-24 X-30 units units units Suppose that Leach Finishing can…arrow_forwardSpecter Company makes 20,000 units per year of a part it uses in the products it manufactures.The unit product cost of this part is computed as follows:Direct materials $25.10Direct labour 18.20Variable manufacturing overhead 2.40Fixed manufacturing overhead 13.40Unit product cost $56.70An outside supplier has offered to sell the company all these parts it needs for $56.00 a unit. Ifthe company accepts this offer, the facilities now being used to make the part could be used tomake more units of a product that is in high demand. The additional contribution margin on thisother product would be $50,000 per year.If the part were purchased from the outside supplier, all the direct labour cost of the part wouldbe avoided. However, $5.10 of the fixed manufacturing overhead cost being applied to the partwould continue even if the part were purchased from the outside supplier. This fixedmanufacturing overhead cost would be applied to the company's remaining products.Required:Part a:Calculate…arrow_forwardFremont Computer Company has been purchasing carrying cases for its portable computers at a purchase price of $78 per unit. The company, which is currently operating below full capacity, charges factory overhead to production at the rate of 40% of direct labor cost. The unit costs to produce comparable carrying cases are expected to be as follows: Direct materials $52 Direct labor 20 Factory overhead (40% of direct labor) 8 Total cost per unit $80 If Fremont Computer Company manufactures the carrying cases, fixed factory overhead costs will not increase and variable factory overhead costs associated with the cases are expected to be 10% of the direct labor costs. Required: a. Prepare a differential analysis dated September 30 to determine whether the company should make (Alternative 1) or buy (Alternative 2) the carrying case. Refer to the lists of Labels and Amount Descriptions for the exact wording of the answer choices for text entries. For those…arrow_forward

- The make or buy decision Lakeview Engine Inc. produces engines for the watercraft industry. An outside manufacturer has offered to supply several component parts used in the engine assemblies, which are currently being produced by Lakeview. The supplier will charge Lakeview $270 per engine for the set of parts. Lakeview's current costs for those part sets are direct materials, $160; direct labor, $80; and manufacturing overhead applied at 100% of direct labor. Variable manufacturing overhead is considered to be 20% of the total, and fixed overhead will not change if the part sets are acquired from the outside supplier. bd 1200 Required: Should Lakeview Engine continue to make the part sets or accept the offer to purchase them for $270? Ovinarrow_forwardYou make widgets, which is a subassembly for you main product of whatsup. An outside vendor has provided you with a quote to supply the widget part for $ 72.00 per unit Your cost records show the following: Your projected production for the widget is 12,500 units Item of Cost Per Unit Cost Direct Material $18.75 Direct Labor $38.00 Variable manufacturing overhead $9.25 Lease on manufacturing facility $36,000.00 per year Depreciation of equipment $2.50 Allocated Corporate Expenses $1.25 If this offer is accepted, you can sublease the manufacturing facility for $15,000 per year All direct and variable costs can be avoided. The equipment has no salvage value How much would net operating income be changed if the outside supplier offer was accepted? Show all calculations for full creditarrow_forwardGhuarrow_forward

- Jordan electronics currently produces the shipping containers it uses to deliver the electronics products it sells. The monthly costs of producing 9,100 containers follow Unit-level material $6,000 Unit-level labor $6,700 unit-level overhead $3,300 product-level costs* $11,700 Allocated facility-level costs $26,500 *one-third of these costs can be avoided by purchasing the containers. Russo container company has offered to sell comparable containers to Jordan for $2.80 each. Required a) Calculate the total relevant cost should Jordan continue to make the containers. b) Jordan could lease the space it currently uses in the manufacturing process if leasing would produce $11,700 per month, and calculate the total avoidable costs. Should Jordan continue to make the containers? a) Total relevant cost should Jordan continue to make the containers? Total avoidable cost Should Jordan continue to make the containers?arrow_forwardVishnuarrow_forwardplease step by step solution.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning,

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning, Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning,

Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning, Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON

Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education

Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Accounting

Accounting

ISBN:9781337272094

Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.

Publisher:Cengage Learning,

Accounting Information Systems

Accounting

ISBN:9781337619202

Author:Hall, James A.

Publisher:Cengage Learning,

Horngren's Cost Accounting: A Managerial Emphasis...

Accounting

ISBN:9780134475585

Author:Srikant M. Datar, Madhav V. Rajan

Publisher:PEARSON

Intermediate Accounting

Accounting

ISBN:9781259722660

Author:J. David Spiceland, Mark W. Nelson, Wayne M Thomas

Publisher:McGraw-Hill Education

Financial and Managerial Accounting

Accounting

ISBN:9781259726705

Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting Principles

Publisher:McGraw-Hill Education