Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

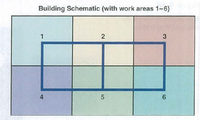

| Roy Creasey Enterprises, a machine shop, is planning to move to a new, larger location. The new building will be 60 feet long by 40 feet wide. Creasey envisions the building as having six distinct production areas, roughly equal in size. He feels strongly about safety and intends to have marked pathways throughout the building to facilitate the movement of people and materials. See the following building schematic. His foreman has completed a month-long study of the number of loads of material that have moved from one process to another in the current building. Tllis information is contained in the following flow matrix. Finally, Creasey has developed the following matrix to indicate distances between the work areas shown in the building schematic. What is the appropriate layout of the new building? |

Transcribed Image Text:Building Schematic (with work areas 1-6)

1

3

4.

2.

Transcribed Image Text:Flow Matrix between Production Processes

TO

FROM MATERIALS WELDING DRILLS LATHES GRINDERS BENDERS

Materials

100

50

50

Welding

25

50

Drills

25

50

Lathes

25

20

Grinders

50

100

Benders

10

20

Finally, Creasey has developed the following matrix to indicate

distances between the work areas shown in the building schematic.

Distance between Work Areas

2

3

4

20

40

20

40

60

20

40

20

40

60

40

20

4

20

40

20

6.

CO

5

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 6 steps with 6 images

Knowledge Booster

Similar questions

- Objectives Prepare by thinking about where to locate your business. Instruction Explain the importance of a business’s location and some key factors in determining the appropriate location. What are the key things to consider in determining the layout of the operations of the business? How does a business control the quality of its products and operations?arrow_forwardWhat is DESIGNING PROCESS LAYOUTS?arrow_forwardMunson Manufacturing, in Gainesville, Florida, wants to arrange its four work centers so as to minimize interdepartmental parts handling costs. The flows and existing facility layout are shown in the figures below. Figure 1. Parts Moved Between Work Centers A A B C D Figure 2. Existing Layout A -30¹- B -|· -30'- 350 0 0 a) For the existing layout, the cumulative "load x distance" or "movement cost" = -30'- Based on the flows shown in the matrix, one should expect that the centers A and -30'- Based on the flows shown in the matrix, one should expect that centers C and b) The aim is to improve the layout so that the total "movement cost" can be reduced. located between them is: D B 420 feet (enter your response as a whole number). A 0 0 -30'- The cumulative distance based on the overall movement of parts between work centers for this layout= C 600 225 will be next to each other as they have the highest number of moves between each other. 0 will be next to each other as they have the…arrow_forward

- 17. In planning a layout for a kitchen renovation, what additional equipment would be required for a ready prepared foodservice operation that would not be mandatory in a conventional foodservice organization? Blant chillerarrow_forwardYou have just been hired as the director of operations for Reid Chocolates, a purveyor of exceptionally fine candies. Reid Chocolates has two kitchen layouts under consideration for its recipe making and testing department. The strategy is to provide the best kitchen layout possible so that food scientists can devote their time and energy to product improvement, not wasted effort in the kitchen. You have been asked to evaluate the two kitchen layouts and to prepare a recommendation for your boss, Mr. Reid, so that he can proceed to place the contract for building the kitchens. Figure 1. Number of trips between work centers To: From: Refrigerator Counter Sink Storage Stove Refrigerator (1) 9 5 5 0 4' Counter (2) 10 For layout number one, the cumulative "load x distance" or "movement cost" = 12 0 8 Sink (3) 13 4 Sink (3) 0 The first kitchen layout is shown in Figure 2 below. The walking distance between the areas is in feet. For example, the distance from area 1 to area 2 is 4 feet, area…arrow_forwardMunson Manufacturing, in Gainesville, Florida, wants to arrange its four work centers so as to minimize K interdepartmental parts handling costs. The flows and existing facility layout are shown in the figures below. Figure 1. Parts Moved Between Work Centers A A B C D 375 0 0 Figure 2. Existing Layout A B 1-30'--1-30-1-30' C D B 450 0 0 a) For the existing layout, the cumulative "load x distance" or "movement cost" = whole number). C 550 175 0 D 50 0 725 feet (enter your response as aarrow_forward

- Topic 4 - PROCESS&TECHNOLOGY AND CAPACITY&FACILITY DESIGNa.Discuss a few objectives of facility layout, and why capacity needed to be understood?b. Elaborate the meaning of process innovation, and how did/can you apply it in your group project given during the academic semesterc.Define in brief about; i. Process Designii. Process Strategyiii. Process Planningiv.Capital Intensityv. Process Flexibilityarrow_forward2022 Develop a solution for the following line balancing problem. Task ABN T K R S Task Time (second) 70 60 120 60 240 100 190 Task Predecessor(s) A B N, T A K.R Allowing a cycle time of 6 minutes, design a NEW process using "the most following task" heuristic approach. Mark the correct answer O Workstation 1: (T); Workstation 2: (K); Workstation 3: (S) Workstation 1: (A,B,N); Workstation 2: (K): Workstation 3: (S) Workstation 1: (A.R): Workstation 2: (S) Workstation 1: (A,B.N.T); Workstation 2: (K.R): Workstation 3: (s)arrow_forwardMunson Manufacturing, in Gainesville, Florida, wants to arrange its four work centers so as to minimize interdepartmental parts handling costs. The flows and existing facility layout are shown in the figures below. Figure 1. Parts Moved Between Work Centers A D A 450 600 50 350 200 725 D Figure 2. Existing Layout A B -30 -30 -30 a) For the existing layout, the cumulative "load x distance" or "movement cost" = feet (enter your response as a whole number).arrow_forward

- Problem: A Akram Plumb's job shop has four work areas, A, B, C, and D. Distances in feet between centers of the work areas are: Distance Between Work Areas in Feet B с D A 35 40 30 B 25 20 D A B C 10 Workpieces moved per week between pairs of work areas, are: Darrow_forwardTopic 4 - PROCESS&TECHNOLOGY AND CAPACITY&FACILITY DESIGNThe design committee has collected a data on patient movement in General Hospital, Kuala Lumpur. The design committee would like to relocate the current layout of six rooms in such that the rooms become more efficient and customer-friendly. Number of patient movement from all rooms are given as in Table Q4d.(table Q4d added) No. 1 to 6 stands for:1 = Intake Dept., 2 = Examination room, 3 = Radiology,4 = Laboratory, 5 = Orthopedics, 6 = Waiting room(Figure Q4d added)From the above data;i. Analyze the non-adjacent loads for the CURRENT LAYOUT of the six rooms as shown in Figure Q4d.ii. If the current layout is relocated as NEW LAYOUT 1 and NEW LAYOUT 2 as shown in Figure Q4d, determine the new non-adjacent loads for both new layouts.iii. Comments on your result. Note: Number of patient movement = LoadNon-adjacent loads = loads given by non-adjacent (not neighbour) roomsarrow_forwarddo fast.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.