Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

Transcribed Image Text:Problem:

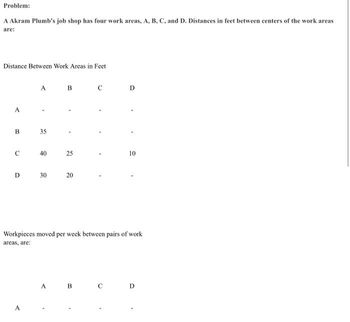

A Akram Plumb's job shop has four work areas, A, B, C, and D. Distances in feet between centers of the work areas

are:

Distance Between Work Areas in Feet

B

с

D

A

35

40

30

B

25

20

D

A B C

10

Workpieces moved per week between pairs of work

areas, are:

D

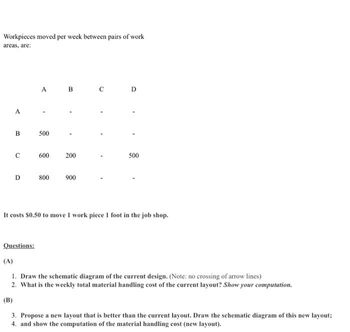

Transcribed Image Text:Workpieces moved per week between pairs of work

areas, are:

B

C

D

A B C

Questions:

500

600

800

200

900

D

500

It costs $0.50 to move 1 work piece I foot in the job shop.

(A)

1. Draw the schematic diagram of the current design. (Note: no crossing of arrow lines)

2. What is the weekly total material handling cost of the current layout? Show your computation.

(B)

3. Propose a new layout that is better than the current layout. Draw the schematic diagram of this new layout;

4. and show the computation of the material handling cost (new layout).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 5 steps with 8 images

Knowledge Booster

Similar questions

- In an evaluation of labor assignment rules when workers are not perfectly interchangeable, Paul. M. Bobrowski and Paul Sungchil Park created a dynamic job shop with 9 work centers and 9 workers, both numbered 1–9. The efficiency of each worker is specified in the following labor efficiency matrix, which represents the degree of worker cross-training.† Work Centers 1.00 0.95 0.95 0.95 0.95 0.85 0.85 0.85 0.85 0.85 1.00 0.95 0.95 0.95 0.95 0.85 0.85 0.85 0.85 0.85 1.00 0.95 0.95 0.95 0.95 0.85 0.85 0.85 0.85 0.85 1.00 0.95 0.95 0.95 0.95 0.85 0.85 0.85 0.85 0.85 1.00 0.95 0.95 0.95 0.95 0.95 0.85 0.85 0.85 0.85 1.00 0.95 0.95 0.95 0.95 0.95 0.85 0.85 0.85 0.85 1.00 0.95 0.95 0.95 0.95 0.95 0.85 0.85 0.85 0.85 1.00 0.95 0.95 0.95 0.95 0.95 0.85 0.85 0.85 0.85 1.00 W o r k e r s (a) For what work center(s) is worker 2 least efficient? (Enter your answers as a comma-separated list.) (b) For what…arrow_forwardIn a job shop, there are four machines: a miller, a planer, a drill, and a packager. The natural process times (in minutes) for each of the machines are: 8, 8, 10, and 13, respectively. The critical WIP of the system, if the four machines are connected in the order given is:arrow_forwardA local toy manufacturer is using a production line that runs 8 hours per day and produces a toy that requires a total of 7 tasks to be performed. The daily demand is 100 toys. Times of the tasks are 2.73, 2.01, 2.13, 2.0, 2.61,2.71, and 2.95 minutes for A, B, C, D, E, F, and G, respectively. However, due to the nature of the product there are precedence rules that must be observed. Such that Task A does not need any predecessors; task B requires task A to be completed. To start task C and task D, each require task B to be completed. Task C must be completed prior to stating task E. Task F needs both task D and task E to be completed. Finally, task G can start only once task F is completed.Given we apply the most remaining tasks rule for balancing the assembly line, with ties broken according to longest task time first, What will the estimated idle time in minutes for FOURTH workstation? Oa. 1.00 O b. None is the correct answer Oc. 0.06 O d. 1.85 O e. 0.09 S PAGE NEXT PAGE e here to…arrow_forward

- Find the value of X in the following Flow Shop data consisting of 5 jobs which are to be processed on two machines M1 & M2 in that order. Jobs M1 M2 A 13 21 B 8 16 C 30 25 D 11 27 E 15 25 For the sequence using Johnson’s Rule, the Make span = Xarrow_forwardA new surgical facility called Cut & Sew has opened in the United States. The branches of the facility are spread throughout the country. These are job shops that handle a variety of outpatient surgical procedures. The process of the facility is set up in a way that one doctor will cut and another will sew. The data regarding the patients and the estimated time for cutting and sewing for each patient are given in the following table: Patient A Cut Time (hours) 2.3 2.5 Sew Time (hours) 2.8 3.0 1.5 1.0 2.8 IB 2.0 0.6 3.8 If we apply the following sequence B-C-D-A-E, the makespan is place). Type your precise answer (one decimal Your Answer: Answerarrow_forwardA local toy manufacturer is using a production line that runs 8 hours per day and produces a toy that requires a total of 7 tasks to be performed. The daily demand is 100 toys. Times of the tasks are 2.73, 2.01, 2.13, 2.0, 2.61, 2.71, and 2.95 minutes for A, B, C, D, E, F, and G, respectively. However, due to the nature of the product there are precedence rules that must be observed. Such that Task A does not need any predecessors; task B requires task A to be completed. To start task C and task D, each require task B to be completed. Task C must be completed prior to stating task E. Task F needs both task D and task E to be completed. Finally, task G can start only once task Fis completed. Given we apply the most remaining tasks rule for balancing the assembly line, with ties broken according to longest task time first, What will the estimated idle time in minutes for THIRD workstation? O a. 1.00 O b. None is the correct answer 0.06 O d. 1.85 e. 0.09arrow_forward

- An assembly task was broken down into four elements, and timed using the continuous timing method. The resulting data and performance ratings are provided below. Calculate the total standard time for this task. Element 1 2 3 4 Watch Time 1.85 2.96 5.42 7.10 Observed Time Rating 95 105 120 115 Normal Time Total ST Standard Timearrow_forwardFind the value of X in the following Flow Shop data consisting of 5 jobs which are to be processed on two machines M1 & M2 in that order. M2 Jobs A 7 B 5 C D E M1 5 2 1 4 13 3 6 3 For the sequence using Johnson's Rule, the Average Flow Time Xarrow_forwardAs the Cottrell Bicycle Co. of St. Louis completes plans for its new assembly line, it identifies 25 different tasksin the production process. VP of Operations Jonathan Cottrell now faces the job of balancing the line. He lists precedencesand provides time estimates for each step based on work-sampling techniques. His goal is to produce 1,000 bicycles perstandard 40-hour workweek.Balance this operation using the shortest operation time rule and compute the efficiency of the line.arrow_forward

- The table below shows the time for each work element in an manual assembly process, along with the predecessor(s) required for each element. The ideal cycle time is 1.4 minutes, the repositioning time is 0.1 minutes, and there is one worker at each station. Work element A B C D E F G H I J Time (minutes) 0.7 0.4 0.2 0.3 0.5 0.4 0.6 0.5 0.3 0.2 Immediate predecessors - A A B B C E,F D,E G,H I 1. Using the ranked positional weights method, assign work elements to stations.arrow_forwardA work cell in a local manufacturer has a workstation with 4 machines that form a line (Machine 1-Machine 2-Machine 3-Machine 4). Each unit needs to pass through each machine in order to be completed. Each machine has a production capacity of four units per hour. What is the process time of the work cell in minutes per unit? 15 4 8 16arrow_forwardA local toy manufacturer is using a production line that runs 8 hours per day and produces a toy that requires a total of 7 tasks to be performed. The daily demand is 100 toys. Times of the tasks are 2.73, 2.01, 2.13, 2.0, 2.61, 2.71, and 2.95 minutes for A, B, C, D, E, F, and G, respectively. However, due to the nature of the product there are precedence rules that must be observed. Such that Task A does not need any predecessors; task B requires task A to be completed. To start task C and task D, each require task B to be completed. Task C must be completed prior to stating task E. Task F needs both task D and task E to be completed. Finally, task G can start only once task F is completed. Given we apply the most remaining tasks rule for balancing the assembly line, with ties broken according to longest task time first, the tasks that will be assigned to the THIRD workstation are O a. E only O b. D and F OC. B, C, and D d. None is the correct answer O e. D onlyarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.