FINANCIAL ACCOUNTING

10th Edition

ISBN: 9781259964947

Author: Libby

Publisher: MCG

expand_more

expand_more

format_list_bulleted

Concept explainers

Topic Video

Question

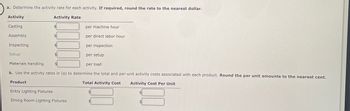

Transcribed Image Text:a. Determine the activity rate for each activity. If required, round the rate to the nearest dollar.

Activity Rate

Activity

Casting

Assembly

Inspecting

$

per machine hour

per direct labor hour

per inspection

Setup

per setup

Materials handling

per load

b. Use the activity rates in (a) to determine the total and per-unit activity costs associated with each product. Round the per unit amounts to the nearest cent.

Product

Total Activity Cost Activity Cost Per Unit

$

Entry Lighting Fixtures

Dining Room Lighting Fixtures

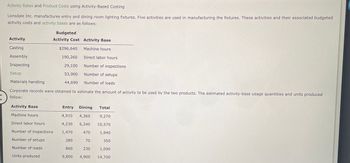

Transcribed Image Text:Activity Rates and Product Costs using Activity-Based Costing

Lonsdale Inc. manufactures entry and dining room lighting fixtures. Five activities are used in manufacturing the fixtures. These activities and their associated budgeted

activity costs and activity bases are as follows:

Budgeted

Activity Cost Activity Base

Machine hours

Direct labor hours

Number of inspections

Number of setups

Number of loads

Activity

Casting

Assembly

Inspecting

Setup

Materials handling

Corporate records were obtained to estimate the amount of activity to be used by the two products. The estimated activity-base usage quantities and units produced

follow:

Activity Base

Machine hours

Direct labor hours

Number of inspections

Number of setups

Number of loads

Units produced

$296,640

190,260

29,100

53,900

44,690

Entry Dining Total

4,910 4,360

9,270

4,230 6,340 10,570

1,470

470

1,940

280

350

860

70

230

1,090

9,800 4,900 14,700

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Similar questions

- Panamint Systems Corporation is estimating activity costs associated with producing disk drives, tapes drives, and wire drives. The indirect labor can be traced to four separate activity pools. The budgeted activity cost and activity base data by product are provided below. Procurement Scheduling Materials handling Product development Production Disk drives Tape drives Wire drives Activity Cost Activity Base $392,400 Number of purchase orders 233,100 Number of production orders 409,400 Number of moves 708,700 Number of engineering changes 1,526,300 Machine hours Number of Purchase Orders Number of Number Number of of Moves Engineering Changes 11 7 23 Production Orders 4,090 280 1,800 185 12,000 910 The activity-based cost for each disk drive unit is Oa. $793.58 Ob. $21.93 Oc. $235.34 Od. $191.6 1 1,410 740 4,500 Machine Hours 1,800 8,300 11,500 Number of Units 2,300 4,300 2,400arrow_forwardActivity-Based Costing Zeus Industries manufactures two types of electrical power units, custom and standard, which involve four factory overhead activities-production setup, procurement, quality control, and materials management. An activity analysis of the overhead revealed the following estimated activity costs and activity bases for these activities: Activity Activity Cost Activity Base Production setup $ 44,000 Number of setups Procurement 13,500 Number of purchase orders (PO) Quality control 97,500 Number of inspections Materials management 84,000 Number of components Total $239,000 The activity-base usage quantities for each product are as follows: Purchase Setups Inspections Components Unit Volume Orders Custom 290 760 1,200 500 2,000 Standard 110 140 300 200 2,000 400 900 1,500 700 4,000 Total a. Determine an activity rate for each activity. Activity Rates Production Setup Procurement Quality Control Materials Management Activity cost + Activity base /setup /PO $ /inspection…arrow_forwardIndirect Cost Allocation: Direct Method Sprint Manufacturing Company has two production departments, Melting and Molding. Direct general plant management and plant security costs benefit both production departments. Sprint allocates general plant management costs on the basis of the number of production employees and plant security costs on the basis of space occupied by the production departments. In November, the following overhead costs were recorded: Melting Department overhead $110,000 Molding Department overhead 400,000 General plant management 100,000 Plant security 50,000 Other pertinent data follow: Melting Molding Number of employees 35 40 Space occupied (square feet) 10,000 20,000 Machine hours 10,000 2,000 Direct labor hours 4,000 20,000 a. Prepare a schedule allocating general plant management costs and plant security costs to the Meltingand Molding Departments. Department Total Melting…arrow_forward

- Barnett Products manufactures three types of remote-control devices: Economy, Standard, and Deluxe. The company, which uses activity-based costing, has identified five activities (and related cost drivers). Each activity, its budgeted cost, and related cost driver is identified below. Activity Cost Cost Driver Material handling $ 281,000 Number of parts Material insertion 3,060,000 Number of parts Automated machinery 873,000 Machine hours Finishing 194,000 Direct labor hours Packaging 194,000 Orders shipped Total $ 4,602,000 The following information pertains to the three product lines for next year: Economy Standard Deluxe Units to be produced 14,300 9,700 2,600 Orders to be shipped 1,910 580 270 Number of parts per unit 15 20 25 Machine hours per unit 1 2 5 Labor hours per unit 3 3 3 What is Barnett’s pool rate…arrow_forwardActivity Rates and Product Costs using Activity-Based Costing Lonsdale Inc. manufactures entry and dining room lighting fixtures. Five activities are used in manufacturing the fixtures. These activities and their associated budgeted activity costs and activity bases are as follows: Activity Casting Assembly Inspecting Setup Materials handling Activity Base Machine hours Direct labor hours Number of inspections Number of setups Number of loads Units produced Budgeted Activity Cost Activity Base Corporate records were obtained to estimate the amount c activity to be used by the two products. The estimated activity-base usage quantities and units produced follow: Entry Dining Total 5,440 4,830 10,270 4,680 7,030 11,710 1,870 590 2,460 270 810 10,800 Activity Casting Assembly Inspecting Setup Materials handling a. Determine the activity rate for each activity. If required, round the rate to the nearest dollar. Activity Rate $ $ $ $225,940 Machine hours 222,490 39,360 46,860 50,470 $ Direct…arrow_forwardActivity Base Entry Dining Total Machine hours 5,320 4,710 10,030 Direct labor hours 4,570 6,860 11,430 Number of inspections 1,940 610 2,550 Number of setups 310 70 380 Number of loads 700 190 890 Units produced 10,600 5,300 15,900 a. Determine the activity rate for each activity. If required, round the rate to the nearest dollar. Activity Activity Rate Casting per machine hour Assembly per direct labor hour Inspecting 24 per inspection Setup per setup Materials handling per load b. Use the activity rates in (a) to determine the total and per-unit activity costs associated with each product. Round the per unit amounts to the nearest cent. Product Total Activity Cost Activity Cost Per Unit Entry Lighting Fixtures Dining Room Lighting Fixturesarrow_forward

- Activity-Based Costing Zeus Industries manufactures two types of electrical power units, custom and standard, which involve four factory overhead activities—production setup, procurement, quality control, and materials management. An activity analysis of the overhead revealed the following estimated activity costs and activity bases for these activities: Activity Activity Cost Activity Base Production setup $ 44,000 Number of setups Procurement 13,500 Number of purchase orders (PO) Quality control 97,500 Number of inspections Materials management 84,000 Number of components Total $239,000 The activity-base usage quantities for each product are as follows: Setups PurchaseOrders Inspections Components Unit Volume Custom 290 760 1,200 500 2,000 Standard 110 140 300 200 2,000 Total 400 900 1,500 700 4,000 a. Determine an activity rate for each activity. Activity Rates Production Setup Procurement Quality Control…arrow_forwardActivity Rates and Product Costs using Activity-Based Costing Garfield Inc. manufactures entry and dining room lighting fixtures. Five activities are used in manufacturing the fixtures. These activities and their associated budgeted activity costs and activity bases are as follows: Activity BudgetedActivity Cost Activity Base Casting $560,000 Machine hours Assembly 75,000 Direct labor hours Inspecting 30,000 Number of inspections Setup 18,750 Number of setups Materials handling 14,000 Number of loads Corporate records were obtained to estimate the amount of activity to be used by the two products. The estimated activity-base usage quantities and units produced follow: Activity Base Entry Dining Total Machine hours 7,500 12,500 20,000 Direct labor hours 2,000 3,000 5,000 Number of inspections 500 250 750 Number of setups 150 100 250 Number of loads 400 300 700 Units produced 5,000 2,500 7,500 a.…arrow_forwardDawson Company manufactures small table lamps and desk lamps. The following shows the activities per product and the total overhead information: Units Setups Inspections Assembly (dlh) 3,400 3,600 8,800 7,200 Small table lamps Desk lamps 8,400 14,000 43,200 43,200 Total Activity-Base Usage Budgeted Activity Cost 10,800 $109,080 22,400 114,240 75,600 340,200 Activity Setups Inspections Assembly (dlh) The total factory overhead (rounded to the nearest cent) to be allocated to each unit of small table lamps is O a. $80.47 O b. $136.80 O c. $48.28 O d. $104.61arrow_forward

- Activity-Based Product Costing Sweet Sugar Company manufactures three products (white sugar, brown sugar, and powdered sugar) in a continuous production process. Senior management has asked the controller to conduct an activity-based costing study. The controller identified the amount of factory overhead required by the critical activities of the organization as follows: Activity Budgeted Activity Cost Production $415,800 Setup 268,800 Inspection 131,200 Shipping 111,600 Customer service 93,800 Total $1,021,200 The activity bases identified for each activity are as follows: Activity Activity Base Production Machine hours Setup Number of setups Inspection Number of inspections Shipping Number of customer orders Customer service Number of customer service requests The activity-base usage quantities and units produced for the three products were determined from corporate records and are as follows: Machine Hours Number…arrow_forwardplease answer within the format by providing formula the detailed workingPlease provide answer in text (Without image)Please provide answer in text (Without image)Please provide answer in text (Without image)arrow_forwardPanamint Systems Corporation is estimating activity costs associated with producing disk drives, tapes drives, and wire drives. The indirect labor can be traced to four separate activity pools. The budgeted activity cost and activity base data by product are provided below. Activity Cost Activity Base Procurement $364,200 Number of purchase orders Scheduling 243,400 Number of production orders Materials handling 417,300 Number of moves Product development 773,900 Number of engineering changes Production 1,428,300 Machine hours Number of Number of Number Number of Number Purchase Production of Engineering Machine of Orders Orders Moves Changes Hours Units Disk drives 4,120 270 1,500 11 2,200 2,100 Tape drives 2,400 245 500 7 8,500 3,500 Wire drives 11,500 790 3,500 21 10,700 2,400 The activity-based cost for each tape drive unit is Oa. $291.69 Ob. $239.52 Oc. $740.06 Od. $20.21arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning,

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning, Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning,

Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning, Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON

Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education

Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Accounting

Accounting

ISBN:9781337272094

Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.

Publisher:Cengage Learning,

Accounting Information Systems

Accounting

ISBN:9781337619202

Author:Hall, James A.

Publisher:Cengage Learning,

Horngren's Cost Accounting: A Managerial Emphasis...

Accounting

ISBN:9780134475585

Author:Srikant M. Datar, Madhav V. Rajan

Publisher:PEARSON

Intermediate Accounting

Accounting

ISBN:9781259722660

Author:J. David Spiceland, Mark W. Nelson, Wayne M Thomas

Publisher:McGraw-Hill Education

Financial and Managerial Accounting

Accounting

ISBN:9781259726705

Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting Principles

Publisher:McGraw-Hill Education