Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

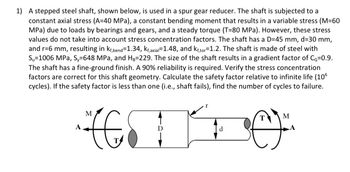

Transcribed Image Text:1) A stepped steel shaft, shown below, is used in a spur gear reducer. The shaft is subjected to a constant axial stress (A=40 MPa), a constant bending moment that results in a variable stress (M=60 MPa) due to loads by bearings and gears, and a steady torque (T=80 MPa). However, these stress values do not take into account stress concentration factors. The shaft has a D=45 mm, d=30 mm, and r=6 mm, resulting in \(k_{t,bend}=1.34\), \(k_{t,axial}=1.48\), and \(k_{t,torsion}=1.2\). The shaft is made of steel with \(S_u=1006\) MPa, \(S_y=648\) MPa, and \(H_B=229\). The size of the shaft results in a gradient factor of \(C_g=0.9\). The shaft has a fine-ground finish. A 90% reliability is required. Verify the stress concentration factors are correct for this shaft geometry. Calculate the safety factor relative to infinite life (\(10^6\) cycles). If the safety factor is less than one (i.e., shaft fails), find the number of cycles to failure.

**Diagram Explanation:**

- The diagram shows a stepped shaft with two different diameters, \(D\) and \(d\).

- The shaft is subjected to a bending moment \(M\) at both ends and a torque \(T\).

- There are forces \(A\) applied axially at the center of the larger diameter section.

- The radius \(r\) of the fillet between the two diameters is indicated.

- The visual aids support understanding of the various forces and geometries impacting the shaft's stress analysis.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The splined ends and gears attached to the steel shaft are subjected to the torques shown in Figure 4. Take G = 75 GN/m². (i) (ii) Determine the location along the 40 mm diameter shaft where the shear stress is largest and plot the variation in shear stress from the shaft centre to its outer surface. Determine the angle of twist of sections C, D, and B relative to end A by producing a graphical plot of the variation of angle of twist from end A to end B (wind-up diagram). 300 N-m 500 N-m A www. 300 mm 200 N.m MAAN 400 mm Figure 4 500 mm 400 N-marrow_forwardCould you answer quickly pls? ( course: strength of materials 1)arrow_forwardA 1.50-in.-diameter solid shaft is subjected to an axial force of P = 1700 lb, a horizontal shear force of V = 180 lb, and a concentrated torque of T = 2200 lb-in., acting in the directions shown. Assume L = 7.5 in. Section properties for the shaft are A = 1.7671 in.2, J = 0.497 in.4, Iy = Iz = 0.2485 in.4, and Q = 0.2812 in.3. Determine the normal and shear stresses at point K, and show these stresses on a stress element.arrow_forward

- In a gear set, a 36-tooth spur pinion drives a 60-tooth spur gear. The teeth of these gear are cast iron profile. The diametral pitch is 6-teeth/in, the face width si 0.5 inches, and the pressure angle is 20 degrees. Assume that the pinion transmits 10 hp at a speed of 2000 rpm. Find the tangential load in lbf Find the contact stress in kpsi, assuming CP=1960 psi.arrow_forwardTwo designs for a shaft are being considered. Both have an outside diameter of 70 m and are 900 mm long. One is solid but the other is hollow with an internal diameter of 50 mm. Both are made from steel (G=120 GPa). Compare the torsional shear stress, angle of twist of the two designs if they are subjected to a torque of 796 N. m.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY