Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Transcribed Image Text:3.

(a)

(b)

(c)

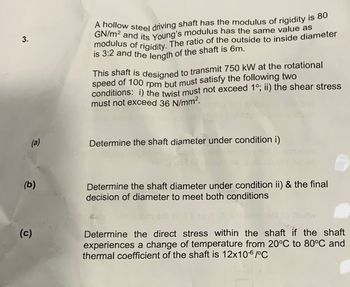

A hollow steel driving shaft has the modulus of rigidity is 80

OGN/m² and its Young's modulus has the same value as

modulus of rigidity. The ratio of the outside to inside diameter

is 3:2 and the length of the shaft is 6m.

This shaft is designed to transmit 750 kW at the rotational

speed of 100 rpm but must satisfy the following two

conditions: i) the twist must not exceed 1°; ii) the shear stress

must not exceed 36 N/mm².

Determine the shaft diameter under condition i)

01

6

Determine the shaft diameter under condition ii) & the final

decision of diameter to meet both conditions

fo

Determine the direct stress within the shaft if the shaft

experiences a change of temperature from 20°C to 80°C and

thermal coefficient of the shaft is 12x10-6/°C

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 5 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The two solid shafts are connected by the gears shown. The motor constantly supplies 20 kW of power at 15 Hz to system at A. The yield shear stress is 140 MPa for shaft (1) and 220 MPa for the shaft (2), and over all factor of safety is 2. a) Find the diameter of both shafts. b) If the modulus of rigidity of shaft (2) G is 77.2 GPa, calculate the relative angle of twist D with respect to C. 30 teeth B (1) 48 teeth Tp 0.8 marrow_forwardA composite shaft shown, composed of a steel (G = 77 GPa) core inside an aluminum (G = 25 GPa) jacket, carries a torque, T = 10 kN-m. The shaft is designed such that the aluminum jacket will fail first upon the application of the torque.What must be the minimum shear strength of steel such that the aluminum jacket will fail first? (Please explain)arrow_forwardProblem 3arrow_forward

- Problem 2. A 300-mm diameter solid disk is to be used as a flywheel in a machine to reduce speed fluctuations. If the disk material has yield strength S Y =720 MPa, density p=7000 kg/m^ 3 . and Poisson's ratio J = 0.2 ^ c , find the maximum allowable rotational speed (in rpm) for a safety factor of 1. a) Solve using the MSST. b) Solve assuming that the disk is mad of cast iron having Sut = 207MPa , Fuc = 780MPa, p = 7000 kg/m³, and Poisson's ratio v r = 0.26 , Use Coulomb-Mohr theory.arrow_forwardThe splined ends and gears attached to the steel shaft are subjected to the torques shown in Figure 4. Take G = 75 GN/m². (i) (ii) Determine the location along the 40 mm diameter shaft where the shear stress is largest and plot the variation in shear stress from the shaft centre to its outer surface. Determine the angle of twist of sections C, D, and B relative to end A by producing a graphical plot of the variation of angle of twist from end A to end B (wind-up diagram). 300 N-m 500 N-m A www. 300 mm 200 N.m MAAN 400 mm Figure 4 500 mm 400 N-marrow_forwardFigure 1 is presented the solid shaft AB rotates at 650 rpm and transmits 30 kW from the motor machine tools connected to gears F and G. Assuming that, 10 kW is taken off at gear F and 20 k taken off at gear G, knowing that allowable torsional shear stress is equal to (65 plus last digit of student ID) MPa. Design the smallest permissible diameter of shaft AB. Figure 1 150 mm 225 mm 905 mm 150 mm 60 mm 100 mm D. 60 mm B.arrow_forward

- Could you answer quickly pls? ( course: strength of materials 1)arrow_forward8.9 (A/B). A solid steel shaft of 200 mm diameter transmits 5 MW at 500 rev/min. It is proposed to alter the horsepower to 7 MW and the speed to 440 rev/min and to replace the solid shaft by a hollow shaft made of the same type of steel but having only 80% of the weight of the solid shaft. The length of both shafts is the same and the hollow shaft is to have the same maximum shear stress as the solid shaft. Find: (a) the ratio between the torque per unit angle of twist per metre for the two shafts; (b) the external and internal diameters for the hollow shaft. [L.Mech.E.] [2.085; 261, 190 mm.]arrow_forward(2) The shaft consists of a 3-in diameter aluminum segment that is rigidly joined to a 2-in diameter steel segment. The ends of the shaft are attached to rigid supports, Calculate the angle of twist developed at the interface of the two segments when the torque T = 50 kip in is applied. Use G = 4×106 psi for aluminum and G = 12×106 psi for steel. | Aluminum 3-in. diameter 6 ft T Steel 2-in. diameter 3 ft Darrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY