Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

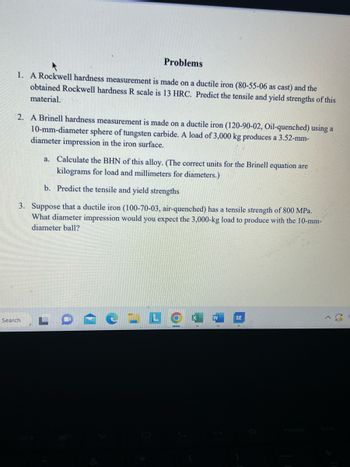

Transcribed Image Text:Problems

1. A Rockwell hardness measurement is made on a ductile iron (80-55-06 as cast) and the

obtained Rockwell hardness R scale is 13 HRC. Predict the tensile and yield strengths of this

material.

2. A Brinell hardness measurement is made on a ductile iron (120-90-02, Oil-quenched) using a

10-mm-diameter sphere of tungsten carbide. A load of 3,000 kg produces a 3.52-mm-

diameter impression in the iron surface.

a. Calculate the BHN of this alloy. (The correct units for the Brinell equation are

kilograms for load and millimeters for diameters.)

b. Predict the tensile and yield strengths

3. Suppose that a ductile iron (100-70-03, air-quenched) has a tensile strength of 800 MPa.

What diameter impression would you expect the 3,000-kg load to produce with the 10-mm-

diameter ball?

Search

LO

W

SE

Expert Solution

arrow_forward

Step 1

“Since you have posted a multiple question, we will provide the solution only to the first question as per our Q&A guidelines. Please repost the remaining questions separately.”

Given data:-

ductile iron specification= 80-55-06

Rockwell's hardness R scale = 13 HRC.

To find:-the tensile and yield strengths of this material.

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- If you could produce AISI 1020 steel with a grain size of 50 nm, what would be the expectedyield stress, assuming a Hall--Petch response? ( MPa, k=0.56 MN/m3/2). Explain eachterm in H-P relation.arrow_forward3000 kg, 10mm Steel Ball Brinell Hardness Reading of 421 is equal to what Rockwell C Reading?arrow_forwardResearch or journal about Failure of Materials Due to Creep and Fatigue. Please include the reference, Range of year from 2000 to 2022!arrow_forward

- Based on the stress-strain plots, which materials tested are stiff and which are tough? How can you tell the difference? * we tested (Steel HR250)and (Aluminium 5251)in this experimentarrow_forward(ii) The turbine blade root is found to contain a surface fatigue crack of 3.3 mm during a routine maintenance inspection. The major stop-start load cycle is experienced twice per day with a minimum stress of 34 MPa and a maximum stress of 195 MPa. The turbine blade has a KIC of 75 MPa√m. Fatigue crack growth rate data for this alloy is given by: the Paris law constant, A = 4.5 x 10-11 and the Paris law exponent, m = 3.8. How many more stop-starts would you recommend be used? Explain your reasoning. You can assume the shape factor Q = 1.2, K is in MPaNm and a (crack length) is in marrow_forwardDetermine the material property of the materials from the following website. Material Property Data (www.matweb.com) e Material: Carbon Steel C1045 (AISI 1045) Cold Drawn 1 in. round Property: Ultimate Tensile Strength (psi) 49,900arrow_forward

- Determine the material property of the materials from the following website. Material Property Data (www.matweb.com) Material: Carbon Steel C1045 (AISI 1045) Cold Drawn - 1 in. round Property: %Elongation at Break (%) 12arrow_forwardFor a certain high-temperature alloy, failure was reported after 4100 hrs at 680°C when subjected to a stress level of 270 MPa. If the same stress were applied at 725°C, how long would the sample be expected to last? State any assumptions you must make to allow you to make this determination.arrow_forwardIn the Table below Data for Mar M 247-a Nickel base superalloy is shown. (1) Plot the steady state strain rate and time to rupture to predict a relationship between the two variables. Provide an equation for the relationship that you see. (2) Give an explanation as to why the fracture elongation is going up with stress.arrow_forward

- A high-strength steel has yield strength of 1165 MPa and fracture toughness of 95 MPavm. Calculate the size of an internal crack that will lead to catastrophic failure at an applied stress of 80% yield strength. (Y = 1.00 for internal crack, and Y=1.12 for surface crack)arrow_forwardDraw a Stress/Strain graph of a mild tensile steel and identify the limit of proportionality and the yield pointarrow_forwardWhat is the maximum internal flaw size allowable for a 304 Stainless steel alloy that is loaded to a stress two thirds of its yield strength (205 MPa) and it has a fracture toughness of 95 MPa.m0.5. Assume a value of 1.3 for Yarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY