Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

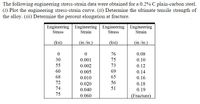

Transcribed Image Text:O The following engineering stress-strain data were obtained for a 0.2% C plain-carbon steel.

(i) Plot the engineering stress-strain curve. (ii) Determine the ultimate tensile strength of

the alloy. (iii) Determine the percent elongation at fracture.

Engineering Engineering Engineering Engineering

Stress

Strain

Stress

Strain

(ksi)

(in./in.)

(ksi)

(in./in.)

76

0.08

30

0.001

75

0.10

55

0.002

73

0.12

60

0.005

69

0.14

68

0.010

65

0.16

72

0.020

56

0.18

74

0.040

51

0.19

75

0.060

(Fracture)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- An aircraft component is fabricated from an aluminum alloy that has a plane strain fracture toughness of 31 MPa/m. It has been determined that fracture results at a stress of 227 MPa when the maximum (or critical) internal crack length is 2.47 mm. a) Determine the value of Yo√a for this same component and alloy at a stress level of 340 MPa when the maximum internal crack length is 1.24 mm. i MPa √//m b) Under these circumstances will the component fail? No Yes Unable to Determine 3arrow_forwardQ1. (i) Initial strain Please enter your supplied question data Q1. (ii) Eo B (hr¹Pa-¹) n IVICUITO Fracture 0.003 Please enter your answers here Your Q1. (i) Answers: 4.60E-34 Q1. (ii) 3.2 Q2. o (Pa) σo (Pa) 780,000,000 Q3. t (hr) Q2. A component is made from a metal that is known to be viscoelastic and behaves according to a secondary creep rate equation with constants of B and n provided as your input values. If the component is subjected to a constant force that results in the initial strain of E provided to you, determine the design stress for a secondary creep life of 1,000 hrs before attaining a limiting strain, &, of 0.01. Q3. If the same component is subjected to a constant displacement that results in the value of initial stress, o, provided to you, calculate the time for the stress to reduce to 200MPa. Young's modulus of the bolt is E = 200GPa.arrow_forwardQuestion 5: Following is tabulated data that were gathered from a series of Charpy impact tests on a tempered 4140 steel alloy. Temperature (°C) 100 75 50 25 0 -25 -50 -65 -75 -85 -100 -125 -150 -175 Impact Energy (J) 89.3 88.6 87.6 85.4 82.9 78.9 73.1 66.0 59.3 47.9 34.3 29.3 27.1 25.0 (a) Plot the data as impact energy versus temperature. (you can use Excel or other software). (b) Determine a ductile-to-brittle transition temperature as that temperature corresponding to the average of the maximum and minimum impact energies. (c) Determine a ductile-to-brittle transition temperature as that temperature at which the impact energy is 70 J.arrow_forward

- Q1/A structural part is 1-meter-long and subjected to a 50 KN load in which this part must be deformed elastically without experiencing any permanent deformation. If you know that part is made of steel, brass, aluminum, and Titanium alloys and the yield strengths and densities of these alloys are: 860 MPa, 7.9 g/cm³; 415 MPa, 8.5g/cm³; 310 MPa, 2.7 g/cm³; and 550 MPa, 4.5 g/cm³ respectively. Based on these criteria, rank the alloys from the heaviest to the lightest in weight.arrow_forwardCalculate the ductility of this steel alloy in %EL.arrow_forwardM 1:-A O photo_2021-02-1.. -> 200 stress 150 (MPa) L00 50 0.1 0-2 strain From the tensile stress-strain behavior fer the brass specimen the foibuding:- O the diameter is 12-8 mm Calcalate 1- The Yield stress. 2- Modulus of elasticity. 3 - The Tensile strength . IIarrow_forward

- Question 1 The S-N diagram for a titanium alloy is shown in the figure. Calculate the fraction of life consumed by the following sequence of loadings: 15,000 cycles at 80 MPa 120,000 cycles at 60 MPa 3,500,000 cycles at 50 MPa Maximum stress (ksi) 160 140 120 100 80 60 40 20 I 10³ 104 105 Cycles to failure 100 107arrow_forwardOne.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY