Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

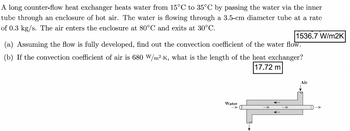

Transcribed Image Text:A long counter-flow heat exchanger heats water from 15°C to 35°C by passing the water via the inner

tube through an enclosure of hot air. The water is flowing through a 3.5-cm diameter tube at a rate

of 0.3 kg/s. The air enters the enclosure at 80°C and exits at 30°C.

1536.7 W/m2K

(a) Assuming the flow is fully developed, find out the convection coefficient of the water flow.

(b) If the convection coefficient of air is 680 W/m².K, what is the length of the heat exchanger?

17.72 m

Water

Air

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The water (C, = 4180 J/kg - °C) enters the 2.5-cm internal-diameter tube of a double-pipe counter-flow heat exchanger at 17°C at a rate of 3 kg/s. It is heated by steam condensing at 120°C (he = 2203 kJ/kg) in the shell. If the overall heat transfer coefficient of the heat exchanger is 1500 W/m? - °C, determine the length of the tube required in order to heat the water to 80°C. Steam 120°C Water 80°C 17°C 3 kg/sarrow_forwardHot coolant water is supplied to a shell and tube heat-exchanger with two shells and twelve tube passes at rate of 1.5 kg/s and a temperature of 350°C. The heat exchanged is used to warm 2.6 kg/s of process water from 15°C to 125°C. Determine the required heat-transfer surface-area when the overall heat transfer coefficient is 1700 W/m-K. You may assume that the water pressure is sufficiently high so that no phase changes occur within the system and the water specific heat is constant at 4.18 kJ/kg.K. Answer: m2arrow_forwardConsider two heat exchanger configurations: parallel-flow and counter-flow. For both configurations cooling water at a flow rate of 1.5 kg/s enters the heat exchanger at 30°C and exits at 45.1°C. This water cools unused engine oil at a flow rate of 1 kg/s from 95°C to 50°C. Both configurations have the same overall heat transfer coefficient of 9,000 W/m2/K. Determine the following: 1. What is the required heat transfer area for each configuration? 2. Give that both configurations have the same inlet and outlet temperatures, what is the basis of the different areas calculated in part a?arrow_forward

- A shell-and-tube heat exchanger is used for cooling 47 kg/s of a process stream flowing through the tubes from 160°C to 100°C. This heat exchanger has a total of 100 identical tubes, each with an inside diameter of 2.5 cm and negligible wall thickness. The average properties of the process stream are r = 950 kg/m3, k = 0.50 W/m·K, cp = 3.5 kJ/kg·K and m = 2.0 mPa·s. The coolant stream is water (cp = 4.18 kJ/kg·K) at a flow rate of 66 kg/s and an inlet temperature of 10°C, which yields an average shellside heat transfer coefficient of 4.0 kW/m2·K. Calculate the tube length if the heat exchanger has (a) a one-shell pass and a one-tube pass and (b) a one-shell pass and four-tube passes.arrow_forwardWater enters at 20 ℃ at a rate of 0.2 kg/s in a double-pipe parallel flow heat exchanger is to be heated to 70 ℃ by geothermal water that enters the heat exchanger at 155 ℃ at a rate of 0.3 kg/s. The overall heat transfer coefficient of the heat exchanger is 500 W/m2. ℃. The internal diameter of the tube is 1.2 cm. Determine the length of the heat exchanger. The specific heats of the water and geothermal water are given to be 4.18 and 4.31 kJ/kg.℃, respectively. Select one: a. 25.4 m b. 30.5 m c. 20.7 m d. 27.5 marrow_forwardThe oil (cp= 1759 J/kg.℃) from an oil cooled electric transformer is cooled from 79.5℃ to 29.4℃ at the rate of 1360.5kg per hour. This is done in an oil-water heat exchanger that receives 2948kg/hr of water at 15.6℃. For the heat exchanger U=295 W/m2℃. Find the exit temperature of water. answer: 25.294 degrees Carrow_forward

- based on a double-pipe counter flow heat exchanger to be used to cool oil that enters the heat exchanger at 300°F to 105°F at a rate of 5 lbm/s by water that enters at 70°F at a rate of 3 Ibm/s. The diameter of the tube is 1 in. and the length is 20 ft. The measured overall heat transfer coefficient of this heat exchanger is 2.14 Btu/s-ft2-°F. [Oil, c, = 0.525 Btu/lbm°F, Water, c, = 1.0 %3D Btu/lbm°F] The logarithmic mean temperature difference in °C is 46.1 cannot be determined 35.0 59.4arrow_forwardQ14) A 65-kg beef carcass (k-0.47 W/m °C and a-0.13x10-6 m²/s) initially at a uniform temperature of 37°C is to be cooled by refrigerated air at -6°C flowing at a velocity of 1.8 m/s. The average heat transfer coefficient between the carcass and the air is 22 W/m2°C. Treating the carcass as a cylinder of diameter 24 cm and height 1.4 m and disregarding heat transfer from the base and top surfaces, determine how long it will take for the center temperature of the carcass to drop to 4°C. Also, determine if any part of the carcass will freeze during this process. Air -6°C Beef 37°Carrow_forwardExhaust gas at 400°C and 1 bar from internal-combustion engines flows at the rate of 125 mol-s¹ into a waste-heat boiler where saturated steam is generated at a pressure of 1200kPa. Water enters the boiler at 20°C (To), and the exhaust gases are cooled to within 10°C of the steam temperature. The heat capacity of the exhaust gases is Cp /R =3.34 + 1.12 x10-³ T/K. The steam flows into an adiabatic turbine and exhausts at a pressure of 25 kPa. If the turbine efficiency n is 72%, (a) What is Ws, the power output of the turbine? (b) What is the thermodynamic efficiency of the boiler/turbine combination? (c) Determine SG for the boiler and for the turbine. (d) Express Wlost (boiler) and Wlost (turbine) as fractions of | Wideal ], the ideal work of the process.arrow_forward

- A heat exchanger is being used to transfer heat between water and a benzene. The benzene enters the heat exchanger at 1.2 m3/h with a temperature of 90 C. The water enters the heat exchanger at 1 m3/h at a temperature of 15°C. The UA product of the heat exchanger is found to be 2800 kJ/h-°K. . Determine (a) the outlet temperature of water and benzene (b) the heat transfer rate between the fluids for a counter-flow heat exchanger.arrow_forwardA counter-flow heat exchanger is used to cool oil (cp = 2.20 kJ/kg⋅ºC) from 110ºC to 85ºC at a rate of 0.75 kg/s by cold water (cp = 4.18 kJ/kg⋅ºC) that enters the heat exchanger at 20ºC at a rate of 0.6 kg/s. If the overall heat transfer coefficient is 800 W/m2⋅ºC, the heat transfer area of the heat exchanger is a. 0.760 m2 b. 0.790 m2 c. 0.805 m2 d. 0.745 m2 e. 0.775 marrow_forwardCold water (cp = 4180 J/kg×K) leading to a shower enters a thin-walled double-pipe counterflow heat exchanger at 15°C at a rate of 0.25 kg/s and is heated to 45°C by hot water (cp = 4190 J/kg×K) that enters at 100°C at a rate of 3 kg/s. If the overall heat transfer coefficient is 950 W/m2×K, determine the rate of heat transfer and the heat surface area of the heat exchanger using the effectiveness–NTU method.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY