Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

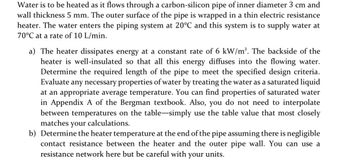

Transcribed Image Text:Water is to be heated as it flows through a carbon-silicon pipe of inner diameter 3 cm and

wall thickness 5 mm. The outer surface of the pipe is wrapped in a thin electric resistance

heater. The water enters the piping system at 20°C and this system is to supply water at

70°C at a rate of 10 L/min.

a) The heater dissipates energy at a constant rate of 6 kW/m². The backside of the

heater is well-insulated so that all this energy diffuses into the flowing water.

Determine the required length of the pipe to meet the specified design criteria.

Evaluate any necessary properties of water by treating the water as a saturated liquid

at an appropriate average temperature. You can find properties of saturated water

in Appendix A of the Bergman textbook. Also, you do not need to interpolate

between temperatures on the table-simply use the table value that most closely

matches your calculations.

b) Determine the heater temperature at the end of the pipe assuming there is negligible

contact resistance between the heater and the outer pipe wall. You can use a

resistance network here but be careful with your units.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- An electric generator at a power plant produces energy by passing superheated steam from a high temperature container (reservoir), through a pipe connected to a series of fans, and then into a low temperature reservoir. As the steam passes across the blades of the fans some of the heat energy of the steam is transformed into mechanical energy, which turns the fans which in turn are connected to a generator, which in turn converts the mechanical energy into electrical energy. If the high temperature steam has a temperature of 436.7 K and the low temperature reservoir has a temperature of 106.7 K, what is the Carnot efficiency of this process?arrow_forwardHot exhaust gases of a stationary diesel engine are to be used to generate steam in an evaporator. Exhaust gases (cp = 1051 J/kg·K) enter the heat exchanger at 550°C at a rate of 0.25 kg/s while water enters as saturated liquid and evaporates at 200°C (hfg = 1941 kJ/kg). The heat transfer surface area of the heat exchanger based on water side is 0.5 m2 and overall heat transfer coefficient is 1780 W/m2·K. Determine the rate of heat transfer, the exit temperature of exhaust gases, and the rate of evaporation of water.arrow_forwardCalculate the rate of infiltration heat loss of a room with a 150m^2 floor area and 3.6m high ceilings. Use an inside temperature of 20°C, an outside ambient temperature of 37.4°C, and an hourly ACH of 0.2 m^3. Assume the heat capacity of air is 0.717W/°C•m^2.arrow_forward

- A camper has a propane-powered refrigerator. The refrigerator consumes approximately 0.50 kgof propane per day. When propane is burned completely, it releases approximately 50. MJ/kg.The interior of the refrigerator is maintained at an average temperature of 2.0 °C, and theexterior temperature is 22 °C. Assume that the refrigerator has a surface area of 2.0 m2 and thatthe insulation has an R-value of 3.2 K · m2/W.(a) At what rate does heat flow into the refrigerator?(b) At what rate must the refrigerator remove heat from its interior?(c) How much energy is released per second from the propane combustion?(d) How much heat is delivered to the room?arrow_forwardConsider two heat exchanger configurations: parallel-flow and counter-flow. For both configurations cooling water at a flow rate of 1.5 kg/s enters the heat exchanger at 30°C and exits at 45.1°C. This water cools unused engine oil at a flow rate of 1 kg/s from 95°C to 50°C. Both configurations have the same overall heat transfer coefficient of 9,000 W/m2/K. Determine the following: 1. What is the required heat transfer area for each configuration? 2. Give that both configurations have the same inlet and outlet temperatures, what is the basis of the different areas calculated in part a?arrow_forwardQuestion #7 Steam at 320°C flows in a stainless steel pipe (k-15W/m K) whose inner and outer diameter are 5cm and 5.5cm respectively. The pipe is covered with 3cm thick glass wool insulation (-0.038W/mK). Heat is lost to the surroundings at 5°C by natural convection and radiation, with a combined natural convection and radiation heat transfer coefficient of h 15W/m² K. Taking the heat transfer coefficient inside the pipe to be happe = outside pipe = 80 W/m²K. (A) Draw the schematic diagram of this problem and label all quantities. (B) Draw the thermal network diagram of this problem and label all thermal resistors and the direction of heat flow. (C) Determine the (i) inner surface area (ii) outer surface area (iii) inner thermal resis- tance (iv) outer thermal resistance (v) thermal resistance across pipe and (vi) thermal resistance across insulation. (D) Determine the total thermal resistance for the unit length of pipe. (E) Determine the rate of heat loss from the steam per unit…arrow_forward

- determine the efficiency of the heat transfer process if a dry air parcel is heated by the earths surface at 15 c and rises adiabatically to the tropopause at -40 c. Assume the parcel follows the carnot cyclearrow_forwardA long thin-walled double-pipe heat exchanger with tube and shell diameters of 2 cm and 4 cm, respectively, is used to condense refrigerant-134a by water at 20 C. The refrigerant flows through the tube, with a convection heat transfer coefficient of hi = 4000 W/m2 K.A 1-mm-thick layer of limestone (k = 1.2 W/mK) forms on the outer surface of the inner tube. Water flows through the shell at a rate of 0.4 kg/s. Determine the overall heat transfer coefficient U of this heat exchanger with and without the fouling factor, and the error in U introduced by neglecting the fouling factor. Comment the fouling effect on this heat exchanger.arrow_forwardThe condenser of a large thermal power plant is a body-tube type heat exchanger consisting of a single body and 30000 pipes with two passes each. The pipes are thin-walled with an inner diameter of 25 mm, and steam condenses on the outer surfaces of the pipes with a convection coefficient of 11000 W / m2.K. The heat transfer required by the heat exchanger is 2000 MW, and it is provided by the flow of water through the pipes at a flow rate of 30000 kg / h. Water enters at 20 ° C, steam condenses at 50 ° C. Calculate the temperature of the cooling water leaving the condenser? Determine the required pipe length per pass? The properties of water at Tort = 300 K; Cp = 4180 j / kgK, μ = 855 × 10--6 Ns / m2, k = 0.613 W / mK, Pr = 5.83.arrow_forward

- A heat recovery device involves transferring energy from the hot flue gases passing through an annular region to pressurized water flowing through the inner tube of the annulus. The inner tube has inner and outer diameters of 24 and 30 mm and is connected by 8 struts to an insulated outer tube of 45-mm diameter. Each strut is 3 mm thick and is integrally fabricated with the inner tube from carbon steel (k = 50 W/m-K). D₂ D₁,2 Dil ↓ Water 1=3 mm Gas h Consider conditions for which water at 300 K flows through the inner tube at 0.161 kg/s while flue gases at 800 K flow through the annulus, maintaining a convection coefficient of 100 W/m².K on both the struts and the outer surface of the inner tube. What is the rate of heat transfer per unit length of tube from gas to the water? Use the Dittus-Boelter equation to obtain the water-side convection coefficient. Determine the rate of heat transfer per unit length of tube from gas to the water, in W/m. 9 = i W/marrow_forwardCold water (cp = 4180 J/kg×K) leading to a shower enters a thin-walled double-pipe counterflow heat exchanger at 15°C at a rate of 0.25 kg/s and is heated to 45°C by hot water (cp = 4190 J/kg×K) that enters at 100°C at a rate of 3 kg/s. If the overall heat transfer coefficient is 950 W/m2×K, determine the rate of heat transfer and the heat surface area of the heat exchanger using the effectiveness–NTU method.arrow_forwardA long counter-flow heat exchanger cools water from 40°C to 10°C by passing the water via the inner tube through an enclosure of cold fluid. The water is flowing through a 3-cm diameter tube at a rate of 0.27 kg/s. The cold fluid enters the enclosure at −10°C and has a convection coefficient of 1200 W/m².K. The mass flow rate of the cold fluid and its specific heat are 1.2 kg/s and 1340 J/kg-K, respectively. (a) Assuming the flow is fully developed, find out the convection coefficient of the water flow. (b) What is the length of the heat exchanger? 1554 W/m²K 2 21.9m Water Cold Fluidarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY