Structural Analysis

6th Edition

ISBN: 9781337630931

Author: KASSIMALI, Aslam.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

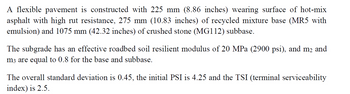

Transcribed Image Text:A flexible pavement is constructed with 225 mm (8.86 inches) wearing surface of hot-mix

asphalt with high rut resistance, 275 mm (10.83 inches) of recycled mixture base (MR5 with

emulsion) and 1075 mm (42.32 inches) of crushed stone (MG112) subbase.

The subgrade has an effective roadbed soil resilient modulus of 20 MPa (2900 psi), and m2 and

m3 are equal to 0.8 for the base and subbase.

The overall standard deviation is 0.45, the initial PSI is 4.25 and the TSI (terminal serviceability

index) is 2.5.

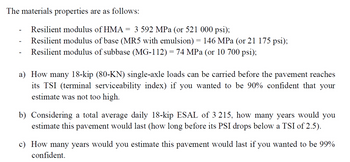

Transcribed Image Text:The materials properties are as follows:

Resilient modulus of HMA = 3 592 MPa (or 521 000 psi);

Resilient modulus of base (MR5 with emulsion) = 146 MPa (or 21 175 psi);

Resilient modulus of subbase (MG-112) = 74 MPa (or 10 700 psi);

a) How many 18-kip (80-KN) single-axle loads can be carried before the pavement reaches

its TSI (terminal serviceability index) if you wanted to be 90% confident that your

estimate was not too high.

b) Considering a total average daily 18-kip ESAL of 3 215, how many years would you

estimate this pavement would last (how long before its PSI drops below a TSI of 2.5).

c) How many years would you estimate this pavement would last if you wanted to be 99%

confident.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 6 steps with 3 images

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

Thank you for you answer, but it's not comlplete.

1- I can't see the right side of the page

2- Question B an C are not answered

Solution

by Bartleby Expert

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

Thank you for you answer, but it's not comlplete.

1- I can't see the right side of the page

2- Question B an C are not answered

Solution

by Bartleby Expert

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- A rigid pavement on a new interstate (3 lanes each direction) has been conservatively designed with a 12- inch slab, an Ec of 5.5 x 106 lb/in2 , a concrete modulus of rupture of 700 lb/in2 , a load transfer coefficient of 3.0, an initial present serviceability index of 4.5, and a terminal serviceability index of 2.5. The overall standard deviation is 0.35, the subgrade CBR is 25, and the drainage coefficient is 0.9. The pavement was designed for 600 30-kip tandem axles per day and 1400 20-kip single axle loads per day. If the desired reliability was 90%, how long was this pavement designed to last? 42 37 18 46arrow_forwardA flexible pavement is constructed with 4 inches of hot-mix asphalt wearing surface, 10 inches soil cement base and 10 inches crushed stone subbase. The subgrade has a soil resilient modulus of 12,000 lb/in2, M2 = 1.5 and M3=1.127 for the materials of the pavement structure. The overall standard deviation is 0.5, the initial PSI = 5.0 and the terminal serviceability index (TSI) is 2.5. The daily traffic has 3000 cars, 1000 trucks and 500 trailers. The axle weights are: How long in years would the pavement last if R = 98% ? (Final answer to 2 decimal places)arrow_forwardA flexible pavement has a structural number of 3.8, the initial PSI is 4.7 and the terminal serviceability is 2.5. The soil has a resilient modulus of 13,000. The overall standard deviation is 0.4 and the design reliability is 95%. The pavement is currently designed for 1800 equivalent 18-kip single-axle loads per day. What is the pavement's design life in years? If the number of 18-kip single-axle loads were to increase by 50%, by how many years would the pavement's design life be reduced?arrow_forward

- Given ESAL = 5 x 10 6, Pe = 2.5%, PP = 0.02%, PSI = 1 .7, and MR = 5000 psi, deter -mine the structural number SN of the mainline and shoulder pavement required for a reliabilityof 50% .arrow_forwardA flexible pavement is constructed with 4 inches of hot-mix asphalt wearing surface, 10 inches soil cement base and 10 inches crushed stone subbase. The subgrade has a soil resilient modulus of 12,000 Ib/in2, M2 = 1.5 and M3=1.127 for the materials of the pavement structure. The overall standard deviation is 0.5, the initial PSI = 5.0 and the terminal serviceability index (TSI) is 2.5. The daily traffic has 3000 cars, 1000 trucks and 500 trailers. The axle weights are: Cars: 20000 lb single axle 10000 lb single axle Trucks: 600O Ib single axle 18000 lb single axle Trailers: 8000 lb single axle 14000 lb tandem axle 40000 lb triple axle How long in years would the pavement last if R = 98% ? (Final %3D answer to 2 decimal places)arrow_forwardi need the answer quicklyarrow_forward

- A flexible pavement is constructed with 3 inches of hot-mix asphalt (HMA) wearing surface, 6 inches of emulsion/aggregate-bituminous base, and 6 inches of crushed stone subbase. The subgrade has a soil resilient modulus of 8,000 lb/in² , and M2 and M3 are equal to 1.0 for the materials in the pavement structure. The overall standard deviation is 0.5, the initial PSI is 4.5, and the TSI is 2.5. The daily traffic has 1080 20-kip single axles, 400 24-kip single axles, and 680 40-kip tandem axles. How many years would you estimate this pavement would last (how long before its PSI drops below a TSI of 2.5) if you wanted to be 90% confident that your estimate was not too high, and if you wanted to be 99% confident that your estimate was not too high?arrow_forward4.13) A rigid pavement is being designed with the same parameters as used in Problem 4.5. The modulus of subgrade reaction is 300 1b/in? and the slab thickness is determined to be 8.5 inches. The load transfer coefficient is 3.0, the drainage coefficient is 1.0, and the modulus of elasticity is 4 million Ib/in?. What is the design modulus of rupture? (Assume that any parameters not given in this problem are the same as those given in Problem 4.5.) 4.5 has been added for reference.arrow_forwardAn interstate highway pavement composed of asphalt surface course, cement treated base course and sand- gravel subbase course is to be designed for an ESAL of 1.2 x 10%. The quality of drainage is considered fair because water can be removed from the subbase within a week. However, there is a large amount of precipitation, so more than 25% of the time the pavement will be exposed to moisture levels approaching saturation. The materials properties are as follows: effective roadbed soil resilient modulus = 5500 psi, resilient modulus of subbase = 15000 psi, unconfined compressive strength of cement-treated base = 500 psi and resilient modulus of asphalt layer 4.3 x 10 psi. Determine the thicknesses of surface, base and subbase courses.arrow_forward

- A flexible pavement is constructed with 3 inches of hot-mix asphalt (HMA) wearingsurface, 6 inches of emulsion/aggregate-bituminous base, and 6 inches of crushedstone subbase. The subgrade has a soil resilient modulus of 8,000 lb/in2 , and M2 andM3 are equal to 1.0 for the materials in the pavement structure. The overall standarddeviation is 0.5, the initial PSI is 4.5, and the TSI is 2.5. The daily traffic has 1080 20-kipsingle axles, 400 24-kip single axles, and 680 40-kip tandem axles. How many yearswould you estimate this pavement would last (how long before its PSI drops below aTSI of 2.5) if you wanted to be 90% confident that your estimate was not too high,and if you wanted to be 99% confident that your estimate was not too high?arrow_forwardA flexible pavement is to be designed to last 10 years. The initial PSI is 4.2 and the TSI (the final PSI) is determined to be 2.5. The subgrade has a soil resilient modulus of 15,000 lb/in². Reliability is 95% with an overall standard deviation of 0.35. For design, the daily car, pickup truck and light van traffic is 40,000 and the daily truck traffic consists of 1500 passes of single-unit trucks with two single axles and 325 passes of tractor semi-trailer trucks with single, tandem, and triple axles. The axle weights are: Cars, pickups, light vans = two 2 kip single axles Single-unit truck = 8 kip single axle and 24 kip single axle Tractor semi-trailer truck = 10 kip single axle, 18 kip tandem axle, and 42 kip triple axle. ● ● M₂ and M3 are equal to 1 for the materials in the pavement structure. Four inches of hot- mix asphalt (HMA) is to be used as the wearing surface and 10 inches of crushed stone as the subbase. Determine the thickness required for the base if soil cement is the…arrow_forwardA flexible pavement is designed to last 10 years to withstand truck traffic that consists only of trucks with two 18-kip single axles. The pavement is designed for a soil CBR of 10, an initial PSI of 5.0, a TSI of 2.5, an overall standard deviation of 0.40 and a reliability of 90%, and the structural number was determined to be 6. Determine the number of daily trucks traveling in the peak direction. 150,814 B 75,407 C) 37,704 18,852arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Structural Analysis (10th Edition)

Civil Engineering

ISBN:9780134610672

Author:Russell C. Hibbeler

Publisher:PEARSON

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Fundamentals of Structural Analysis

Civil Engineering

ISBN:9780073398006

Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel Lanning

Publisher:McGraw-Hill Education

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning