Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

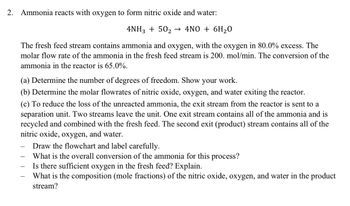

Transcribed Image Text:2. Ammonia reacts with oxygen to form nitric oxide and water:

4NH3 + 50₂ → 4NO + 6H₂O

The fresh feed stream contains ammonia and oxygen, with the oxygen in 80.0% excess. The

molar flow rate of the ammonia in the fresh feed stream is 200. mol/min. The conversion of the

ammonia in the reactor is 65.0%.

(a) Determine the number of degrees of freedom. Show your work.

(b) Determine the molar flowrates of nitric oxide, oxygen, and water exiting the reactor.

(c) To reduce the loss of the unreacted ammonia, the exit stream from the reactor is sent to a

separation unit. Two streams leave the unit. One exit stream contains all of the ammonia and is

recycled and combined with the fresh feed. The second exit (product) stream contains all of the

nitric oxide, oxygen, and water.

Draw the flowchart and label carefully.

What is the overall conversion of the ammonia for this process?

Is there sufficient oxygen in the fresh feed? Explain.

What is the composition (mole fractions) of the nitric oxide, oxygen, and water in the product

stream?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 8 images

Knowledge Booster

Similar questions

- number 8 Please try to solve by Extent reaction or Molecular balance. My professor wants the answer by those methods not chemistry x y way .arrow_forwardAmmonia is produced by the catalytic reaction of nitrogen and hydrogen.a) Write the chemical reaction and balance it. Determine the stoichiometric coefficients.b) If 15 mol/sec of H2 is fed to the reactor, determine the amount of N2 required if a 20.%excess (of N2) is desired.c) If 5.0 mol/sec of H2 exits the catalytic reactor, determine: - the number of moles of all three components exiting the reactor. - the conversion of H2 and N2. -the exiting concentration of H2, N2, and ammonia.d) What are strategies to increase the conversion of H2?arrow_forward#3 The first step in the reaction sequence for the production of nitric acid via the oxidation of ammonia is: 4NH3 + 502 2 4NO + 6H2O 75% conversion is achieved with an equimolar mixture of ammonia and oxygen fed at the rate of 100 mol/h. Determine the outlet compositions. (Hint: determine the limiting reactant).arrow_forward

- Problem 2. There has been a lot of recent interest in oxygen-enhanced combustion. In this process, pure oxygen is added to air which is then fed to a furnace along with the fuel. This increases the combustion temperature, thereby reducing the amount of pollutants and increasing the concentration of CO₂ in the flue gas, making it easier to sequester the CO₂. An Orsat analysis of the flue gas from a furnace which burns methane is as follows: 11.1 mol % CO2, 5.5 mol % O2, and 83.4 mol % N₂ (dry basis). The amounts of CO, SO₂, and CH4 in the flue gas are negligible. a.) How many moles of air were fed to the furnace per mole of pure O₂? b.) What was the percent excess oxygen fed to the furnace?arrow_forwardFor the electrolysis of CuCl2 (molten) to form Cu(s) and Cl2(g):E°Cu2+/Cu = 0.339 VE°Cl-/Cl2 = 1.360 V What minimum voltage must be used to carry out the reaction? If 1.5V is used, how much electrical energy (in kJ) will be used to produce 2g of Cl2(s)?arrow_forwardFresh methanol (CH3OH) reactant is combined with recycled reactant and vaporized before being sent to a fixed-bed reactor. The reactor effluent is then cooled before being sent to the first of two distillation columns. DME (CH3)2O product is taken overhead from the first column. The second column separates the water from the unused methanol. The methanol is recycled back to the front end of the process, and the water is sent to wastewater treatment to remove trace amounts of organic compounds. Draw a block flow diagram for this process. The main reaction is 2CH3OH → (CH3)2O + H2Oarrow_forward

- Aniline is produced by the hydrogenation of nitrobenzene. A small amount of cyclohexylamine is produced as a by-product. Nitrobenzene is fed to the reactor as a vapor with three times the required stoichiometric amount of hydrogen. The conversion of nitrobenzene to the products is 96% and the selectivity to aniline is 85%. Unreacted hydrogen is separated from the reaction products and recycled to the reactor. From the recycle line it is purged to keep the inerts in the recycle stream below 5%. The fresh hydrogen that is fed is 99.5% pure and the rest is inert. Calculate the adiabatic outlet temperature of the reaction products and indicate the relationship with respect to the reference temperature (298.15) (in K):arrow_forwardMaterial and energy balancearrow_forwardA mixture of 90g of N2, 165g of O2 and 45g of Cl2 is introduced to a reactor where the following chemical reaction is carried out in the gas phase, If the reaction has a yield of 85% yield. Calculate the products of the reaction at the outlet. N2+O2→N2O4arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The