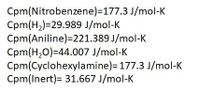

Aniline is produced by the hydrogenation of nitrobenzene. A small amount of cyclohexylamine is produced as a by-product. Nitrobenzene is fed to the reactor as a vapor with three times the required stoichiometric amount of hydrogen. The conversion of nitrobenzene to the products is 96% and the selectivity to aniline is 85%. Unreacted hydrogen is separated from the reaction products and recycled to the reactor. From the recycle line it is purged to keep the inerts in the recycle stream below 5%. The fresh hydrogen that is fed is 99.5% pure and the rest is inert. Calculate the adiabatic outlet temperature of the reaction products and indicate the relationship with respect to the reference temperature (298.15) (in K):

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 24 images

- Problem #3 (35%) Vinyl chloride is synthesized through the following reaction of acetylene and hydrochloric acid: C2 H2+ HCl → CH2CHC The following undesired reaction also occurs simultaneously, producing dichlorethane instead: C2 H2 + 2HCI C2 H4CL2 - These reactions occur in a reactor during the manufacture of vinyl chloride. In this process, the feed to the reactor contains 100 Kmol/h of acetylene. The same feed also contains HCI, 16% in excess of that needed if the desired reaction went to completion, as well as 1.2 Kmol/h of an inert contaminant (water vapor). The single-pass fractional conversion of acetylene in the reactor is 12%, and 94% of the C2H2 so reacted is consumed in the first reaction to form vinyl chloride. The only stream leaving the reactor goes to a separation unit where all the vinyl chloride and all the dichlorethane are condensed and removed through a bottom liquid stream. This liquid stream contains nothing else. The top gaseous stream from the separator is…arrow_forwardShould correctarrow_forwardF2 gas and excess iodine solid are heated together at high temperatures. The iodine sublimes and gaseous iodine heptafluoride forms. A 2.50L reaction vessel contains 350 torr of F2 gas and 2.50g of solid iodine at 250K which is then heated to 550K. What is the number of moles of excess iodine that would be left over once all the fluorine is used up? What is the total pressure at the end of the reaction? What is the partial pressure of the left over iodine gas as the end of the reaction? What is the balanced chemical equation for this reaction?arrow_forward

- The combustion of C3H6 to CO2 and H2O can be described by any of the reactions:C3H6 + 9/2 O2 → 3 CO2 + 3 H2Oor the reaction:2 C3H6 + 9 O2 → 6 CO2 + 6 H2OAssume that 10 moles / h of C3H6 are reacted with 50 moles / h of O2, achieving complete conversion of C3H6.Calculate the reaction rates that are obtained with each reaction. Explain how the two speeds are related and why.arrow_forwardGlycol is produced on commercial scale from ethylene oxide reactant, which is made by the partial oxidation of ethylene with an excess of air over a silver catalyst.The primary reaction is2C2H4 + O2 → 2C2H4OUnfortunately, some of the ethylene also undergoes complete oxidation to CO2 and water via the following reactionC2H4 + 3O2 → 2CO2+ 2H2OSuppose for a feed containing 10% ethylene, an ethylene conversion of 25% and an oxide yield of 80% is obtained from the reactant. Calculate the composition of the reactor outlet stream under such operating conditionsarrow_forwardChemical Engineering Calculation All questions are interconnected, allowed by bartleby. PROBLEM #2: In a process for the manufacture of chlorine by direct oxidation of HCl with air over a catalyst to form Cl2 and H2O, the exit product is composed of 4.4% HCl, 19.8% Cl2, 19.8% H2O, 4% O2, and 52% N2. Detailed Solution in the Following: 0. Draw Process Diagram 1. What is the balanced chemical equation? 2. The limiting reactant is _________. 3. The percentage excess of the excess reactant is _______%. 4. What is the conversion of the limiting reactant? 5. What is the extent of reaction?arrow_forward

- Acetylene (C2H2) may be formed from methane (CH4) by pyrolyzing-decomposing at high temperature according to the reaction: 2CH4 (g) → C2H2 (g) + 3H2 (g) In a commercial reactor system, the methane is supplied as a liquid at 25°C to a heater where it is heated and vapourised leaving as a vapour at 650°C. The vapour then passes to the catalytic reactor in which a conversion of 40% is achieved. It may be assumed that there are no other reactions, that operation is at a pressure of one atmosphere and that the stream leaving the reactor is all in the vapour state. With a complete block diagram of the process, determine the heat transfer rate (kW) required to the reactor if it is operated isothermally. Evaluate on the value of the heat transfer rate obtained from your calculation. Component State Δ?? °(kJ/mol) Cp (kJ/mol·K) Methane Liquid ----------- ---------- Gas -74.85 0.34 Acetylene Liquid ---------- ---------- Gas 226.75 0.42 Hydrogen Gas ---------- 0.059 The Cp…arrow_forward2. Ethanol is produced by the hydration of ethylene according to the first reaction below. However, some of the products are converted to diethyl ether according to the second reaction. C2H4 + H20 – C,H;0H 2C2H;OH - (C2H5)20 + H20 The feed to the reactor contains ethylene, steam, and N2. An effluent analysis is given in the following table: C2H4 39.12 H2O CH;OH 2.95 (C2H3)20 Component %mol With a basis of 100 kmol of effluent, determine the following: N2 45.08 0.27 12.58 b. (. ) Determine the fractional conversion of ethylene.arrow_forwardConsider the pair of reactions in which ethylene is oxidized either to ethylene oxide (desired) or to carbon dioxide (undesired) in the furnace: C₂H4+0₂-C₂H4O C₂H₂ +30₂-2 CO₂ + 2H₂O The feed mixture and air are fed at a temperature To. All gaseous effluents are at temperature T emerging from the non-isothermal reactor. a) Calculate the number of degrees of freedom of the process. How would the answer differ if the reactor were adiabatic? b) Outline a manual calculation procedure to determine the compositions of all streams.arrow_forward

- Methanol (CH3OH) and its derivative products are used as base materials in acrylic plastic, synthetic fabrics, adhesives, paints and as chemical agent in pharmaceuticals and agrichemicals. In petrochemical industry, one promising pathway to produce methanol is from conversion of syngas to methanol via hydrogenation of carbon dioxide and carbon monoxide. The reaction of this process is given as follows, CO + 2H2 → CH3OH (1) CO2 + H2 → CO + H20 (2) Suppose 1000 kmol/hr of syngas with molar composition of 22% CO2, 6.7% CO, 65% H2, 4.1% H20, 1.1% CH4 and 1.1% N2 is used as fresh feed. (a) Draw and label a complete process flow diagram of this process. (b) Calculate the amount of unreacted CO2 if given single pass conversion of CO2 is 14.2%. (c) Calculate the extent of reaction for the side reaction (2) and the amount of water produced. (d) If the selectivity of methanol to water is 92.1%, calculate the amount of methanol produced. (e) Determine mole fraction of CH3OH, CO2, CO, H2, H2O, CH4…arrow_forwardEthane is chlorinated in continuous reactor: C2H6 + Cl2 → C2H5CI + HCl Some of the product monochloroethane is further chlorinated in an undesired side reaction: C2H5CI + Cl2 → C2H4C12 + HCl The reactor is designed to yield a 15% conversion of ethane and a selectivity of 14 mole C2H5C1 /mole C2H4C12, with a negligible amount of chlorine in the product gas. Calculate a) Feed ratio (mole Cl2/mole C2H6 b) Fractional yield of monochloroethane. (Basis: Use 100 moles of C2H5CI produced).arrow_forwardOne of the ways that benzene is produced on a large scale is the hydrodealkylation of toluene. C,H,CH; + H, C,H, + CH4 A stream of toluene is mixed with a recycle stream and enters a reactor along with a stream of pure hydrogen. The reaction products at 550 °C enter a condenser, where they are cooled to 41.0 °C. A vapor stream containing Y5CH, = 0.600 mol CH,/mol leaves the process, and a liquid stream containing x66 = 0.810 mol benzene/mol and x6 = 0.190 mol toluene/mol enters a distillation column. The distillate of the column leaves the process at n7 = 668.0 mol/h and contains y7h = 0.9000 mol benzene/mol and y7 = 0.1000 mol toluene/mol. The bottoms of the column contains X8b = 0.250 mol benzene/mol and xgt = 0.750 mol toluene/mol and is recycled back to the fresh feed. Hydrogen is fed into the process at ni = 1183 mol H,/h. This process is carried out at 760 mmHg. A n, mol/h mol H/mol YSH2 YSCH, mol CH_/mol Ysh mol b/mol Ys mol t/mol n̟ mol/h n, mol/h Condenser Улн, тol H/mol Усн,…arrow_forward

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The